OPGW is the dual shield for earthing & lightning protection in transmission lines

By Staff Report July 3, 2025 6:35 pm IST

By Staff Report July 3, 2025 6:35 pm IST

Steel Products Limited (SPL), a pioneer in live-line OPGW installations, has successfully deployed and commissioned over 45,000 km of OPGW across voltage levels ranging from 132 kV to 765 kV.

In the ever-evolving domain of power transmission, the dual mandate of safeguarding assets and ensuring uninterrupted communication is increasingly being met through a single innovation: Optical Ground Wire (OPGW). Originally designed as a composite conductor that combines the mechanical strength of a ground wire with the data-carrying capacity of optical fibres, OPGW today plays a pivotal role in lightning protection, system grounding, and grid communication.

Role of earthing & lightning protection

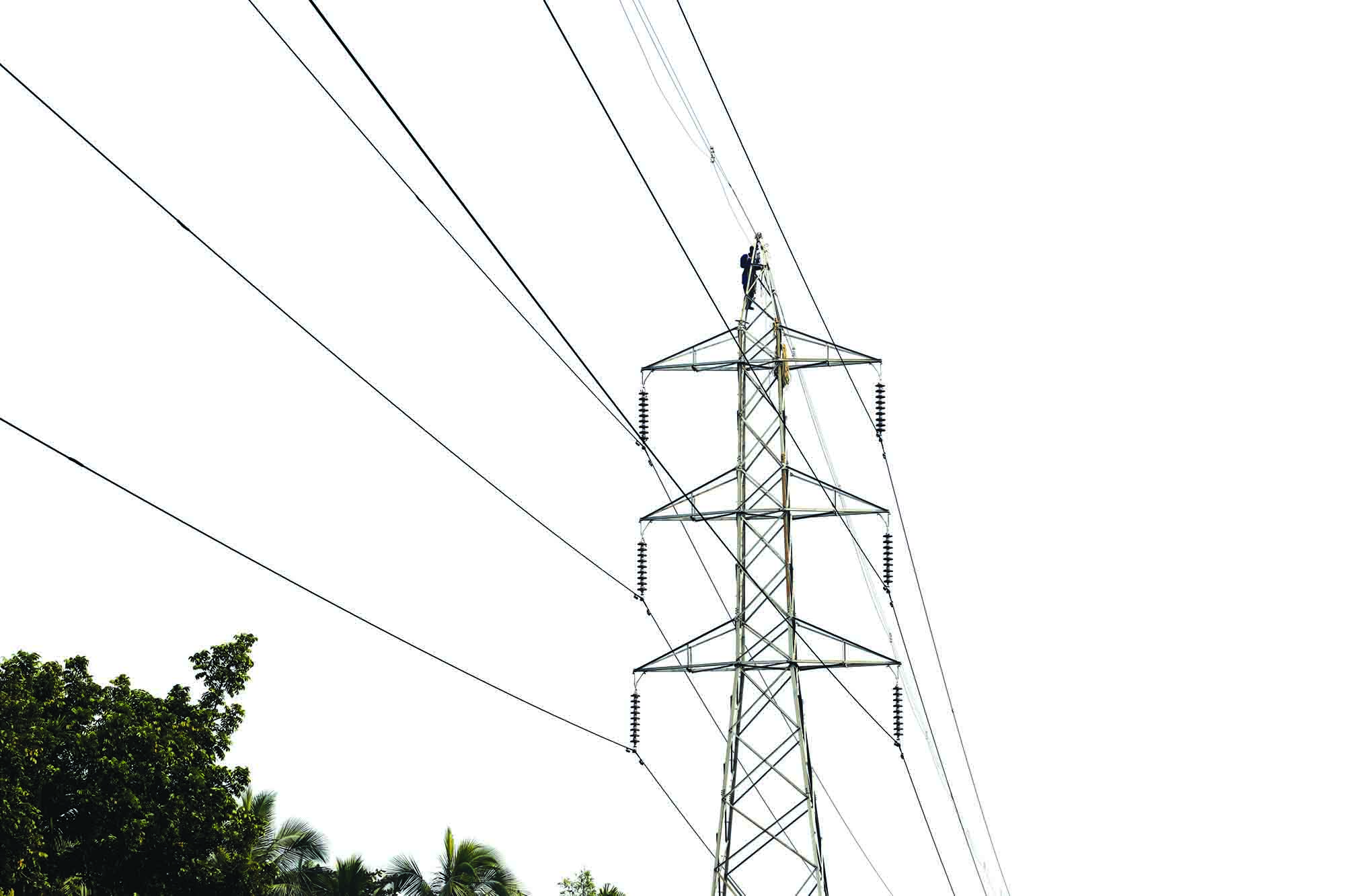

High-voltage transmission lines, especially those operating at 132 kV and above, are naturally exposed to atmospheric discharges. Lightning strikes are a leading cause of faults and outages on transmission networks. In this context, ground wires (also called earth wires or shield wires) are strung above the phase conductors to intercept lightning strokes, channelling them safely into the earth, thus shielding the conductors and associated equipment.

However, conventional ground wires, while effective at dissipating surge energy, do not contribute to grid intelligence. This is where OPGW becomes a transformative asset.

Evolution of ground wire

Optical Ground Wire (OPGW) integrates optical fibres within a metallic ground wire structure, providing primary lightning protection to the phase conductors, a system grounding path for fault currents, and high-speed, reliable communication for SCADA, protection, and utility operations. By replacing standard ground wires with OPGW, utilities are modernising their earthing systems while building a digital backbone for grid automation.

OPGW in lightning performance

OPGW, being metallic in construction (typically of aluminium-clad steel or aluminium alloy wires), retains all characteristics of a conventional earth wire in terms of:

Properly installed OPGW with optimal sag-tension and tower shielding angles contributes significantly to the lightning performance index (LPI) of the transmission line.

Additionally, the optical fibre core remains electrically insulated and is protected against electromagnetic interference, making it a fail-safe channel for protection signalling even during high-voltage transients.

Grounding aspects of OPGW

Each tower in a transmission line must be adequately earthed to dissipate lightning and fault currents into the soil with minimal resistance. When OPGW is used, its continuity is critical for an effective earth path. Key considerations include:

-Bonding and grounding of OPGW at every tower

-Use of grounding clamps with low contact resistance-Maintenance of tower footing resistance (TFR) within design limits, typically below 10 ohms

-Implementation of surge arresters at terminals and critical points

A well-grounded OPGW system can significantly improve lightning flashover performance and reduce line-tripping rates.

Strategic advantages of OPGW deployment

OPGW (Optical Ground Wire) offers a cost-effective and efficient solution by combining grounding and high-speed communication in a single deployment, significantly reducing infrastructure costs. It enables real-time data transmission, essential for grid monitoring, fault detection, load management, and temperature tracking, thereby supporting advanced automation. With a longer lifespan than traditional ground wires or underground fibre, OPGW ensures greater reliability and reduced maintenance needs. Moreover, it utilises existing Right of Way (ROW), eliminating the need for new land acquisition, unlike underground fibre installations. Its cyber-secure communication capabilities make it particularly crucial for safeguarding national transmission networks.

OPGW and live-line installation

To avoid disruptions to grid operation, many utilities now opt for live-line installation of OPGW, where existing ground wires are replaced without de-energising the line. This complex but safe operation demands:

-Specialised live-line tools and equipment

-Trained and skilled crew

-Detailed safety procedures and risk assessment

Steel Products Limited (SPL), a pioneer in live-line OPGW installations, has successfully deployed and commissioned over 45,000 km of OPGW across voltage levels ranging from 132 kV to 765 kV. Leveraging its extensive installation expertise, SPL now maintains a 30,000 km OPGW network spanning four regions across India, ensuring a reliable communication infrastructure.

Authored by:

CEng. Ankit Tinna, General Manager- Steel Products Ltd.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.