The project is integrated with 600 MW/2,400 MWh energy storage systems (ESS). The tender allowed bidders flexibility in choosing project sizes, with a minimum bid of 50 MW and a maximum cap of 600 MW.

SJVN Limited has announced the results of its auction for developing 1,200 MW of interstate transmission system (ISTS)-connected solar power projects integrated with 600 MW/2,400 MWh energy storage systems (ESS). The auction witnessed active participation from several major renewable energy developers, with competitive tariffs being discovered.

SAEL Industries, Jindal India Renewable Energy, Sembcorp Green and JBM Renewables each won capacities of 150 MW, 300 MW, 150 MW, and 150 MW respectively, all quoting a tariff of ₹3.32 per kWh. Fastnote Biofuels (Hindustan Power) was awarded 100 MW at a slightly higher tariff of ₹3.33 per kWh. Reliance NU Energies (a part of Reliance Power) secured 350 MW out of its quoted 600 MW at ₹3.33 per kWh using the bucket-filling method. This auction, initially floated in September 2024, marks a significant step toward enhancing India’s renewable energy portfolio with integrated storage solutions.

The tender allowed bidders flexibility in choosing project sizes, with a minimum bid of 50 MW and a maximum cap of 600 MW. Eligible projects included those under construction, yet to be commissioned, or commissioned but supplying power on a short-term merchant basis. However, projects already accepted under other state or central schemes or those with power purchase agreements (PPAs) in place with designated beneficiaries were excluded.

A key feature of the tender was its technological openness. Developers were permitted to use crystalline silicon, thin-film, or concentrated photovoltaic modules, with or without trackers. Moreover, the tender mandated the use of commercially established and operational technologies to reduce execution risk and ensure timely completion.

This auction highlights the growing momentum of solar-plus-storage projects in India, promoting a stable and flexible renewable energy supply and aiding in grid management through integrated ESS components.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The current revision of the SHAKTI policy, enriched with innovative features, is set to significantly enhance its scope and impact across the power sector.

In a meeting chaired by the PM Narendra Modi held recently Cabinet Committee on Economic Affairs (CCEA) approved the Revised SHAKTI (Scheme for Harnessing and Allocating Koyala Transparently in India) Policy for Coal Allocation to Power Sector. The Revised SHAKTI Policy adds to the series of coal sector reforms being undertaken by the Government.

With the introduction of SHAKTI Policy in 2017, there was a paradigm shift of coal allocation mechanism from a nomination-based regime to a more transparent way of allocation of coal linkages through auction / tariff-based bidding. Now, the multiple paras of the SHAKTI Policy, for coal linkage, have been mapped to only two Windows in the Revised SHAKTI Policy, aligning with the spirit of ease of doing business, encouraging competition, efficiency, better use of capacity, seamless pit head thermal capacity addition and affordable power to the country.

The current revision of the SHAKTI policy, enriched with innovative features, is set to significantly enhance its scope and impact across the power sector. This update aims to provide greater flexibility in coal allocation, broaden the eligibility criteria to include more stakeholders, and improve overall accessibility to coal resources. Together, these changes are expected to strengthen the power sector’s operational efficiency and reliability.

The new policy will ensure coal linkage to all power producers leading to generation of more power, cheaper tariffs and an overall positive impact on the economy, thereby leading to increased employment generation potential. The reliable and affordable power supply to various sectors would catalyse economic activities and support the Atmanirbhar Bharat Initiative. The increased availability of domestic coal, in a simplified manner would also facilitate the revival of remaining stressed power assets. The linkage coal can now be used for generating power from Un-requisitioned Surplus (URS) capacity, for sale in power markets, which will not only deepen power markets by increasing availability of power in power exchanges but will also ensure optimum utilisation of generating stations.

Further, the new linkages offered to the power sector would increase the coal availability for the power sector and increase the mining activities in the coal bearing regions resulting in generation of higher revenue to the State Governments which can be utilised for development of these regions and local population in general. The policy would encourage pit head thermal capacity addition and facilitate imported coal substitution in the Imported Coal Based (ICB) plants that can secure domestic coal thereby reducing their import coal dependency.

The Revised SHAKTI Policy introduces two key windows for granting fresh coal linkages to Thermal Power Plants (TPPs) in the Central Sector, State Sector and Independent Power Producers (IPPs). Under Window-I, coal is allocated at the notified price. The existing mechanism for granting coal linkages to Central Sector TPPs, including Joint Ventures (JVs) and their subsidiaries, will continue. Additionally, coal linkages will be earmarked to States or to an agency authorised by a group of States based on recommendations from the Ministry of Power. These earmarked linkages can be used by State Gencos or IPPs identified through competitive bidding (TBCB) or existing IPPs with a PPA under Section 62 of the Electricity Act, 2003, including for setting up new or expansion units with PPAs under Section 62.

Window-II allows all domestic coal-based power producers, including those using imported coal if required, to obtain coal through an auction by paying a premium over the notified price. This window supports flexibility in electricity sales and offers coal for periods ranging from up to 12 months to as long as 25 years. The revised policy aims to maximise the use of domestic coal, ensure smooth capacity addition in the thermal sector, reduce reliance on imported coal and strengthen the country’s energy independence in line with the government’s objective of ensuring Energy Security for All.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Minister lauded the progress made by Goa in implementing infrastructure upgrades under the Revamped Distribution Sector Scheme (RDSS) to curb losses.

Power Minister Manohar Lal Khattar called on the Goa government to consider the possibility of establishing a nuclear power facility to boost local power generation and ensure long-term energy security and sustainability.

During a high-level review meeting held in Panaji with Goa Chief Minister Dr. Pramod Sawant and senior officials, the Minister highlighted that nearly 80 percent of Goa’s electricity is currently procured from outside the state. He emphasised the importance of exploring all possible avenues for local power generation to enhance self-reliance and reduce dependency.

Commending the Goa Electricity Department for its effective efforts in achieving universal electrification and maintaining consistent power availability, Khattar noted, “Goa has shown exemplary performance by reducing AT\&C (Aggregate Technical and Commercial) losses to 9.32 percent, significantly below the national average. This is a testament to the state’s sustained efforts in improving the efficiency of its power distribution system.”

The Minister lauded the progress made by Goa in implementing infrastructure upgrades under the Revamped Distribution Sector Scheme (RDSS) to curb losses. However, he stressed the need to expedite the rollout of smart meters, calling it a transformative step for consumer engagement with power distribution companies (DISCOMs).

“Now that the contracts have been awarded, I am confident the implementation will gain momentum. Prioritising saturation of smart meters in government offices, colonies, commercial and industrial units and high-load consumers will help ensure digitisation and improved service delivery,” Khattar added.

Highlighting the role of renewable energy in enhancing operational efficiency and reducing power costs, the Minister urged Goa to further integrate clean energy sources into the grid. He also acknowledged the state’s citizen-friendly initiatives in simplifying rooftop solar installations and new electricity connections.

The meeting concluded with an assurance from the Ministry of Power to provide full support to Goa in achieving its energy goals and strengthening its power infrastructure.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

In a unique step towards gender-sensitive care one of the five MMUs exclusively dedicated to women’s healthcare will be staffed entirely by female medical professionals.

REC Limited, has extended financial support of ₹6.01 crore under its Corporate Social Responsibility (CSR) initiatives for the procurement and operation of five Mobile Medical Units (MMUs) in the state of Uttarakhand. The initiative was inaugurated by Pushkar Singh Dhami, Chief Minister of Uttarakhand. The MMUs, deployed in partnership with CSC Academy, will operate across three districts — Haridwar (2 units), Udham Singh Nagar (2 units), and Tehri Garhwal (1 unit) — with a special focus on remote and underserved communities. Outfitted with essential diagnostic and treatment facilities, these units will operate six days a week and are designed to provide free primary healthcare services at the doorsteps of marginalised populations.

In a unique step towards gender-sensitive care, one of the five MMUs is exclusively dedicated to women’s healthcare will be staffed entirely by female medical professionals. This Women’s Mobile Medical Unit aims to address the specific health needs of women in conservative and hard-to-reach regions.The MMUs will function in close coordination with the Chief Medical Officers (CMOs) and the Uttarakhand State Health Department, ensuring alignment with government healthcare strategies and continuity of care. The project is a vital part of the government’s vision of “Swasth Uttarakhand, Samriddh Uttarakhand”, and will contribute to strengthening last-mile healthcare delivery.

This deployment is part of REC Foundation’s wider initiative titled ‘Doctor Aapke Dwaar’, which is already operational through Mobile Health Clinics in other states including Bihar, Chhattisgarh, Tamil Nadu, and Punjab. REC Limited remains steadfast in its mission to bridge the rural healthcare gap and empower lives through sustainable and impactful social responsibility initiatives.

Health Minister of Uttarakhand; Rajesh Kumar, Secretary, Health Department; Sunita Tamta, Director General Health; Sunil Bisht, CPM, REC RO Dehradun; Jha, COO, CSC Academy, and other senior officials from REC and CSC Academy were present at the inauguration.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

This project in Gujarat is slated for commissioning in the first half of 2026 as per the Power Purchase Agreement (PPA) terms.

BluPine Energy announced the successful financial closure of debt funding worth ₹376 crore for its 100 MW solar power project being developed in Tharad, Banaskantha district, Gujarat. The project, undertaken under its wholly owned subsidiary Solarcraft Power India 5 Pvt. Ltd., is being developed under the GUVNL 22 tender. Standard Chartered acted as a Sole Mandated Lead Arranger, Lender, Green Loan Coordinator and Account Bank. The financing documents have been executed for the ₹376 crore project finance green loan secured from Standard Chartered, marking the financial closure of the project.

Sanjeev Bhatia, Chief Financial Officer, BluPine Energy, said, “This closure underpins BluPine’s commitment to financial stewardship, robust corporate governance, and strong execution capabilities. It reinforces our strategy of scaling up clean energy infrastructure while ensuring commercial viability and sustainable returns. As we continue to develop world-class energy solutions to meet India’s growing electricity demands, partnering with premier financial institutions that share our commitment to a cleaner, stronger grid is essential. This is a significant transaction, and we thank our lending partners for their continued confidence in BluPine and our ability to build top-of-the-line energy centers.”

Prasad Hegde, Regional Head, Infrastructure & Development Finance Group, India and South Asia, Standard Chartered, said, “We are delighted to be the first port of call and primary relationship Bank to BluPine in India and ensure timely financial closure of their projects. Standard Chartered is committed to help businesses adapt to climate change, build resilience and provide an opportunity for them to thrive long-term. The Group globally also has plans to mobilise $300 billion in sustainable finance by 2030 which will assist in this journey. India is one of the key markets in the Group for sustainable finance and our work will continue to support the country’s ambition to reduce overall carbon emissions.”

This project is slated for commissioning in the first half of 2026, as per the Power Purchase Agreement (PPA) terms. Once operational, it will contribute significantly to Gujarat’s renewable energy targets and support India’s broader energy transition agenda. BluPine Energy remains focused on expanding its renewable energy footprint with a diversified portfolio of high-quality solar and wind energy projects across India.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

For this ₹5,000 crore project GAIL plans to develop a diversified renewable energy portfolio in the state including ground-mounted solar, rooftop solar, floating solar, wind energy and the required storage solutions.

The Karnataka government has signed a memorandum of understanding (MoU) with GAIL (India) Limited to establish 1 GW of renewable energy capacity in the state with an estimated investment of ₹5,000 crore. The initiative is part of Karnataka’s ongoing efforts to position itself as a leading green energy hub in India.

GAIL plans to develop a diversified renewable energy portfolio in the state, including ground-mounted solar, rooftop solar, floating solar, wind energy and the required storage solutions. The projects will be implemented through land acquisition on a lease basis from farmers or with support from the Karnataka Industrial Areas Development Board (KIADB) for land allocation. The state government has assured swift facilitation of approvals, registrations, and applicable concessions to accelerate the process.

GAIL is also looking to acquire suitable land within the state’s solar parks to speed up implementation under its capital expenditure strategy. This partnership is expected to not only enhance Karnataka’s renewable energy capacity but also contribute significantly to employment generation and infrastructure development in the region.

Karnataka already hosts one of the largest solar parks in the country—Pavagada Solar Park—which produces 2,050 MW of power annually. Building on this success, local farmers have expressed willingness to offer an additional 10,000 acres of land for similar renewable energy projects, providing further scope for expansion.

The MoU was signed in the presence of M.B. Patil, Minister for Large and Medium Industries and Infrastructure Development, K.J. George, Minister for Energy and T.D. Rajegowda, chairman of Karnataka Renewable Energy Development Ltd (KREDL).

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The latest order brings the total contribution to the Khavda Renewable Energy Park to approximately 1.3 GW from Vikram Solar alone.

Vikram Solar Limited secured an order from Gujarat Industries Power Company Limited. It will supply 326.625 MW of high-efficiency solar modules for Khavda Renewable Energy Park—a key project in the Great Rann of Kutch, Gujarat.

The latest order brings its total contribution to the prestigious Khavda Renewable Energy Park to approximately 1.3 GW—a considerable share of this development. Expected to be fully operational by December 2026, the park will also aim to generate employment opportunities in the region.

The modules are scheduled for delivery in FY 25-26, further reinforcing Vikram Solar’s leadership in India’s green energy transition. This order underscores the company’s commitment in delivering high-performance solar modules designed to withstand challenging climatic conditions.

Gyanesh Chaudhary, Chairman & Managing Director of Vikram Solar, stated: “We are thrilled to secure this order, which reinforces the strong and enduring relationship between Vikram Solar and GIPCL. The Khavda project represents more than just scale—it symbolises a collective push toward energy security and sustainability. With this order, we are contributing to one of the most important renewable energy projects in India.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The PMT JV, operator of the Tapti fields under a production sharing contract with the Government of India comprises of ONGC with a 40 percent participating interest and RIL and BG Exploration & Production India Ltd (BGEPIL-Shell) with 30 percent each.

In a landmark achievement for India’s energy sector, the Panna-Mukta and Tapti (PMT) joint venture partners – Shell (through BGEPIL), Reliance Industries Limited (RIL), and Oil and Natural Gas Corporation Limited (ONGC) have successfully completed the country’s first offshore facilities decommissioning project with the safe removal of mid and south Tapti field facilities.

The PMT JV, operator of the Tapti fields under a production sharing contract with the Government of India, comprises of ONGC with a 40 percent participating interest, and RIL and BG Exploration & Production India Ltd (BGEPIL-Shell) with 30 percent each.

The milestone project involved removal of five wellhead platforms, associated infield pipelines, load-in at the onshore dismantling yard and the safe plugging and abandonment of 38 wells – all executed in line with the approved decommissioning plan. Production from the Tapti fields ceased in March 2016, and this project demonstrates a high level of planning, coordination, and compliance with regulatory frameworks while upholding the highest safety and environmental standards.

Aligned with the Government of India’s ‘Make in India’ vision, the PMT JV awarded major contracts to Indian companies Larsen and Toubro (L&T) for offshore execution and Chowgule Shipyard (CLSPL) for onshore dismantling. Offshore operations have now been completed safely, and dismantling is underway at CLSPL’s facilities in Ratnagiri, further strengthening India’s domestic capabilities in offshore and onshore energy infrastructure.

The Tapti decommissioning project also played a pioneering role in shaping India’s regulatory and operational framework for offshore decommissioning. Developed collaboratively with key stakeholders—including the Union Ministry of Petroleum and Natural Gas (MoPNG), Directorate General of Hydrocarbons (DGH), and Oil Industry Safety Directorate (OISD), the project sets a benchmark for future offshore energy transitions, rooted in global best practices and adapted for Indian conditions.

Nipun Pradhan, Managing Director, BGEPIL and GM Shell Upstream India, said, “The safe and successful completion of the Tapti offshore project is a landmark moment for India’s offshore energy sector. This project sets a new benchmark for responsible decommissioning, made possible by global expertise, strong collaboration, and an unwavering commitment to safety and sustainability. Shell is proud to be part of this historic journey alongside our partners Reliance, ONGC, and the Government of India.”

“The safe and responsible offshore decommissioning by the PMT JV marks a significant step forward for India’s energy sector. From the outset, the JV partners worked tirelessly to strengthen local supply chains and enhance the technical and safety capabilities of Indian contractors especially for offshore dismantling activities. This project has successfully delivered on the Indian Government’s ambition of ‘Make and Break in India’,” said Sanjay Barman Roy, President, E&P, Reliance Industries Limited.

Pankaj Kumar, Director (Production), ONGC, remarked, “This first-of-its-kind large-scale offshore decommissioning underscores ONGC’s commitment to responsible energy practices. The project’s complexity, especially its proximity to ONGC’s live assets demanded strategic planning, precise execution, and utmost focus on safety. It marks a defining moment in India’s energy landscape and sets a strong foundation for the next chapter in offshore infrastructure transformation.”

Globally, offshore decommissioning is a complex endeavour, often involving evolving regulations, developing contractor ecosystems, and fluctuating market dynamics. The successful Tapti decommissioning project demonstrates what can be achieved through multi-stakeholder collaboration and serves as a model for environmental responsibility, safety, and efficiency in India’s growing energy transition journey.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

For utility-scale and grid-scale power projects, crystalline silicon (c-Si) modules must maintain a minimum efficiency of 20%, while cadmium telluride (CdTe) thin-film modules are required to meet a threshold of 19%. Similarly, for rooftop solar systems and solar-powered pumps, the minimum efficiency standards remain at 19.5% for c-Si modules and 18.5% for CdTe modules.

The Ministry of New and Renewable Energy (MNRE) has updated the minimum efficiency requirements for solar modules listed under the Approved List of Models and Manufacturers (ALMM). These revisions specifically apply to off-grid solar power projects and applications such as solar lamps, streetlights, fans, and similar systems where each solar module has a capacity of less than 200 Wp. Notably, solar-powered agricultural pumps and rooftop systems are excluded from these changes. Under the revised norms, the minimum efficiency requirement for crystalline silicon (c-Si) modules has been reduced from 19 percent to 18 percent . Meanwhile, the efficiency standard for cadmium telluride (CdTe) thin-film modules remains unchanged at 18 percent.

To accommodate these off-grid systems, MNRE has created a separate list within the ALMM framework, titled ALMM List-I (DRE), which will operate independently from the main ALMM List-I. Additionally, MNRE has introduced a new fourth category called “Any other application.” This includes solar projects that do not fall under utility/grid-scale, rooftop, solar pump, or off-grid classifications. For this category, the minimum efficiency requirements are set at 19 percent for c-Si modules and 18 percent for CdTe thin-film modules.

The minimum efficiency requirements remain unchanged for solar modules across various applications. For utility-scale and grid-scale power projects, crystalline silicon (c-Si) modules must maintain a minimum efficiency of 20 percent, while cadmium telluride (CdTe) thin-film modules are required to meet a threshold of 19 percent . Similarly, for rooftop solar systems and solar-powered pumps, the minimum efficiency standards remain at 19.5 percent for c-Si modules and 18.5 percent for CdTe modules.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

THDC India Ltd., a subsidiary of NTPC is in the final stages of commissioning India’s first Variable Speed Pumped Storage Plant of 1000 MW capacity at Tehri, Uttarakhand.

Pankaj Agarwal, Power Secretary has emphasised that ensuring grid stability is a matter of urgent national priority and every state must actively contribute to this effort. Underlining the need for Sub-regions within states to become self-sufficient from a grid management perspective Pankaj stated that a strong focus should be on flexible generation and load shifting.

The secretary highlighted the current need while speaking on a high-level brainstorming session on “Pumped Storage Projects: Powering India’s Renewable Future” organised at the SCOPE Convention Centre, New Delhi by THDC India Ltd. and Central Electricity Authority (CEA) in association with NTPC with the support of CBIP and INCOLD.

He added that there is a need of brainstorming and policy dialogue to fast-track PSP development, with a focus on reviewing procedural delays and streamlining processes and platforms like these are vital for building consensus and enabling coordinated sectoral action.

Adding to it, Akash Tripathi, Additional Secretary (Hydro) in his address, highlighted that the genesis of this workshop lies in the need to bring together relevant stakeholders to collaborate on accelerating the development of Pumped Storage Projects (PSPs). He noted that the workshop aims to foster brainstorming and exchange of key policy perspectives on how to fast-track PSP implementation

Moreover, M.G. Gokhale, Member (Hydro), CEA highlighted the vast potential of Pumped Storage Projects (PSPs) in India, emphasising their critical role in achieving the country’s Net Zero targets through reliable energy storage. He noted that, around 3 GW of PSP capacity is expected to be added in 2025-26, including the commissioning of the 1000 MW Tehri PSP in the coming months.

The speaker, Gurdeep Singh, CMD, NTPC stressed the urgent need for large-scale deployment of Pumped Storage Projects (PSPs), stating that the energy transition cannot succeed without robust storage solutions. Given the intermittent nature of renewables, he emphasised the need of storage capabilities for a stable shift to renewable energy and reliable grid management. R.K. Vishnoi, CMD, THDCIL welcomed the imminent dignitaries and emphasised that the workshop is aimed at deliberating on the development of Pumped Storage Projects (PSPs). He noted that the focus will be on identifying roadblocks and exploring ways to ensure faster and more efficient execution of projects on the ground. Vishnoi also addressed the scope of automation in various aspects of operations and how it can ensure seamless operations and enhance efficiency.

Deliberations highlighted the urgent need for streamlined policy support, faster clearance mechanisms, robust financing options, and strengthened collaboration between central and state agencies to scale up PSP deployment across India.

Notably, THDC India Ltd., a subsidiary of NTPC, is also in the final stages of commissioning India’s first Variable Speed Pumped Storage Plant of 1000 MW capacity at Tehri, Uttarakhand, having successfully completed critical tests—marking a significant milestone in India’s energy storage journey.

The session witnessed the participation of over 300 distinguished delegates including top government officials, policymakers, developers, environmental experts, regulators, and senior representatives from the public and private sectors from near about 95 organisations and institutions from all around the country. The day-long event focused on the growing role of Pumped Storage Projects (PSPs) in supporting India’s renewable energy transition and achieving the national target of net zero emissions by 2070.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The company recorded an execution amounting to ₹51.95 crore with significant contributions coming from the oil and gas and power sectors, both domestically and via international operations including DEE Thailand.

DEE Development Engineers Limited reported a robust order book with INR 98.36 crore inflow at Group level, closing at INR 1,274.58 crore as of 30th April 2025. The company recorded an execution amounting to ₹51.95 crore, with significant contributions coming from the oil and gas and power sectors, both domestically and via international operations, including DEE Thailand. Notably, the oil and gas segment remained the largest contributor, with a closing order book of ₹938.53 crore.

Commenting on this progress, Krishan Lalit Bansal, Chairman and Managing Director, shared, “Despite broader market challenges, we remain committed to delivering high-quality engineering solutions across the energy, oil and gas, and industrial sectors. We will continue to uphold this standard, reflecting the trust our clients place in us and our ability to execute complex projects reliably. As we expand our global footprint and strengthen our core offerings, our focus remains on building long-term value for our stakeholders while supporting the growth of the industry.”

There is a Power Purchase Agreement (PPA) in place with Punjab Discom for our Biomass Power Generation business. The average billing for the preceding two fiscal years has been ₹80 crore per year. The Punjab State Electricity Regulatory Commission has passed an interim Order revising the tariff of Malwa Power Private Limited for a fixed tariff of Rs. 3.50 per unit as the PPA has expired on 26.04.2025, however, this rate will be revised shortly by a final Order. For ease of understanding, we have considered the order inflow and execution amount to be the same for this period.

With a strong order pipeline, diversified client base, and expanding international operations, DEE Development Engineers Limited remains well-positioned to drive sustained growth and value creation in the coming quarters.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Prime Minister, Narendra Modi

“We are now working on feasibility studies for electricity grid interconnectivity between India and Saudi Arabia and the wider region.”

Anil Saboo, Chairman & MD – Elektrolites (Power) Pvt Ltd

“Any cost incurred or spent on smart grid equipment like Fault Passage Indicators (FPIs), Auto-reclosers and Load Break Switches (LBS) can typically be recovered within 2 to 3 years.”

Kalidas Bhangare, MD- Testo India

“Environmental conditions in the electrical and power sectors directly influence the reliability and longevity of substation equipment and control room operations.”

Hardik Kothiya, Founder and Managing Director- Rayzon Solar

“The biggest advantage of generating solar power near the substation is supporting tail-end distribution by maintaining healthy voltage where, otherwise, the voltage gets dropped.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

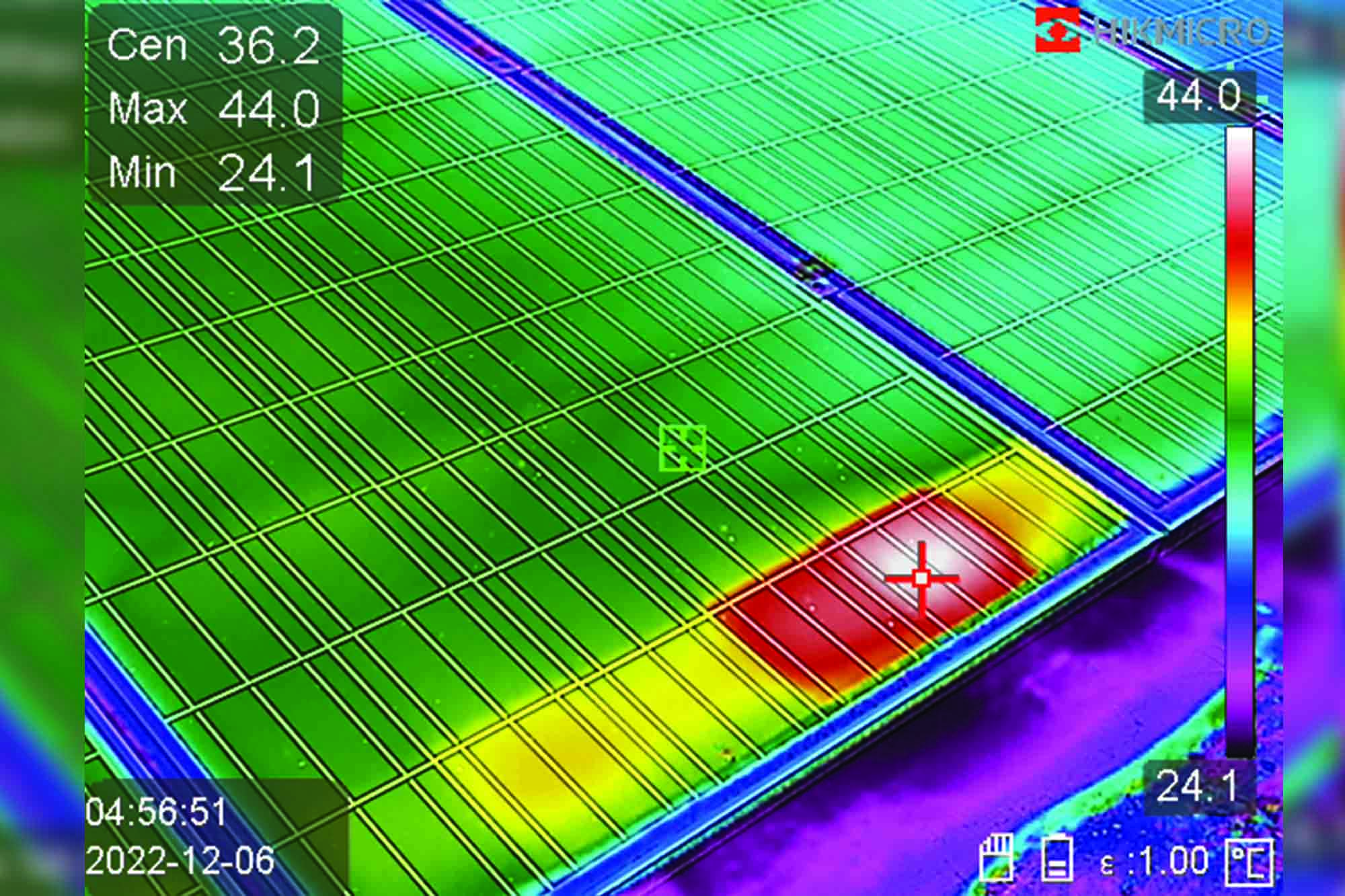

The company’s M Series thermal imaging camera provides a noninvasive method for assessing the health of solar panels and associated components.

As the world increasingly embraces sustainable energy solutions, the blending of cutting-edge technologies becomes increasingly crucial. One such ground-breaking integration is the fusion of thermal imaging with solar energy systems, which offers new avenues for efficiency and optimisation in capturing sun energy.

Enhancing Solar Panel Efficiency with Thermal Imaging

Optimisation in traditional solar panel setups relies heavily on manual adjustments and periodic maintenance. However, we can revolutionise this process by integrating thermal imaging technology pioneered by HIKMICRO’s expertise in the field.

Thermal cameras detect subtle temperature variations across solar panels, identifying areas of inefficiency caused by dust accumulation, shading or faulty cells. Armed with this data, system operators can precisely target cleaning efforts and repairs, ensuring maximum energy output and extending the installation’s lifespan.

Monitoring System Performance and Health

Beyond the initial installation phase, continuous monitoring is essential for the long-term performance of solar energy systems. HIKMICRO’s thermal imaging camera, like the M Series, provides a noninvasive method to assess the health of solar panels and associated components.

Regular thermal scans allow operators to identify potential issues such as overheating, electrical faults or degradation, enabling proactive maintenance and minimising downtime.

Predictive Maintenance and Fault Detection

Drawing on the predictive capabilities of thermal imaging technology, we can anticipate and prevent system failures before they occur with SP Series and G Series. Anomalies detected through thermal scans, such as abnormal temperature gradients or hotspots, are early indicators of underlying issues. Thanks to the early intervention facilitated by HIKMICRO’s innovative thermal imaging solutions, this proactive approach enhances system reliability and reduces operational costs.

Optimising Energy Harvesting in Real-Time

Real-time thermal imaging combined with advanced analytics empowers the dynamic optimisation of energy harvesting strategies. By continuously monitoring solar panel performance and environmental conditions, systems can autonomously adjust parameters such as tilt angle, orientation and tracking mechanisms to maximise energy yield. This adaptive approach ensures optimal operation under varying sunlight intensity and weather conditions, enhancing overall system efficiency and ROI.

Fusing thermal imaging technology with solar energy systems represents a significant step forward in renewable energy management. HIKMICRO’s dedication to innovation and excellence in thermal imaging solutions makes us committed to supporting the advancement of solar energy technologies.

Join us as we unlock solar power’s full potential, leveraging thermal imaging insights to create a brighter, cleaner, and more sustainable future.

***********************************************************************************************************

Authored By:

Ashish P. Dhakan, MD & CEO- Prama Hikvision India Private Limited

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

By adopting cutting-edge technologies like Perovskite solar cells, the company ensures that its energy systems are effective and environmentally responsible, aligning with global sustainability goals.

Solar photovoltaic (PV) systems are pivotal in transitioning substations from reliance on conventional power sources to renewable energy. By harnessing sunlight to generate electricity, these systems offer a sustainable alternative to fossil fuels, thereby reducing greenhouse gas emissions and environmental degradation.

Reducing Dependency on Conventional Power Sources

Integrating solar PV into substations enhances grid resilience and efficiency. It reduces transmission and distribution losses, lowers generation costs and bolsters energy security. This integration is particularly beneficial in regions with high solar irradiance, such as India, where solar energy can significantly offset conventional energy consumption.

Novasys Greenergy, India’s leading renewable energy company, exemplifies this transition. By implementing solar PV systems in substations, the company not only reduces dependency on traditional power sources but also contributes to the country’s renewable energy goals. The company’s initiatives align with the country’s sustainable development and energy independence.

Submersible Substations in Flood-Prone Areas

Floating solar panel farms or floating photovoltaics (FPVs) present an innovative solution for energy generation in flood-prone areas. By installing solar panels on water bodies, FPVs utilise otherwise unused spaces and reduce land-use conflicts. The water-cooling effect enhances panel efficiency, and the shade provided by the panels can reduce evaporation, benefiting the local ecosystem.

Integrating FPVs with submersible substations in flood-prone regions ensures continuous power supply during flooding events. Submersible substations are designed to operate underwater, maintaining grid stability when traditional substations might fail. The combination of FPVs and submersible substations offers a resilient energy infrastructure capable of withstanding extreme weather conditions.

Novasys is at the forefront of deploying such integrated systems in India. By leveraging FPVs alongside submersible substations, the firm addresses the dual challenges of land scarcity and flooding, ensuring reliable and sustainable energy access in vulnerable regions.

Innovations Enhancing Efficiency and Sustainability

Recent advancements in solar panel technology have significantly improved energy efficiency and sustainability. Perovskite solar cells, for instance, offer higher efficiency rates and lower production costs than traditional silicon-based cells. These cells can be manufactured using less energy-intensive processes, reducing their environmental impact.

Bifacial solar panels capture sunlight from both sides and can increase energy output by up to 30 percent in environments with reflective surfaces. Additionally, lightweight and flexible solar panels are expanding the applicability of solar energy to diverse settings, including disaster relief and remote areas.

Novasys Greenergy incorporates these innovations into its solar solutions, enhancing the efficiency and sustainability of its projects. By adopting cutting-edge technologies, the company ensures that its energy systems are not only effective but also environmentally responsible, aligning with global sustainability goals.

Financing Models Supporting the Manufacture of Solar Panels

Innovative financing models are crucial for scaling up solar panel manufacturing in India. Power Purchase Agreements (PPAs) and solar leasing allow businesses and consumers to adopt solar energy with minimal upfront costs, paying only for the electricity generated. Pay-as-you-go (PAYG) systems and community financing models make solar energy accessible to low-income households and small enterprises.

Government initiatives such as green bonds and concessional loans further support the renewable energy sector by providing flexible lending terms and reducing investment risks. These financial mechanisms encourage private sector participation and facilitate the expansion of solar manufacturing capacities.

Novasys leverages these financing models to enhance its manufacturing capabilities. By utilising innovative financial instruments, the firm can invest in advanced technologies and expand its production, contributing to the country’s renewable energy targets and economic growth.

India is undergoing a significant transition toward sustainable energy, including modernising its critical power infrastructure. In this ongoing change, Novasys Greenergy is playing a crucial role. By integrating advanced solar technologies and building resilient energy systems, the company is reducing dependence on conventional power sources, improving energy access, and paving the way for a cleaner, more secure energy future.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Advanced solutions such as gas-insulated switchgear (GIS) are gaining traction due to their compact design, environmental benefits and lower maintenance requirements.

The global energy landscape is profoundly transforming due to urbanisation, industrial growth, renewable energy integration and the push for sustainability. In India, these shifts are reshaping the electrical infrastructure, with switchgear innovations emerging as a cornerstone of efficient and sustainable power distribution systems. As sustainability and environment-friendly solutions progress, next-generation switchgear solutions are poised to play an important role in enabling smarter and safer energy management.

Evolving Electrical Landscape in India

Rapid urbanisation and industrialisation have significantly increased energy demands in India. Government initiatives such as ‘Make in India’, ‘Smart Cities Mission’, and ‘PM-KUSUM’ drive infrastructure development and renewable energy adoption. While these continued efforts have created robust opportunities for advanced switchgear solutions, integrating renewable energy sources like solar and wind power into the grid has created unique challenges for switchgear design, creating a need for more advanced, smarter and sustainable solutions. The systems must address fluctuating loads and decentralised power generation while maintaining efficiency. Advanced solutions such as gas-insulated switchgear (GIS) are gaining traction due to their compact design, environmental benefits and lower maintenance requirements.

The accelerating energy demands in India, marked by a surge in electricity consumption at ~9 per cent annually since FY2021 (compared to 5 per cent in the previous decade), as highlighted in the CEEW study, underscore the urgency of modernising grid infrastructure amid rapid renewable energy adoption. Notably, the CEEW analysis emphasises that smart grid technologies, including GIS with real-time monitoring, could enable demand flexibility to avert ₹14,000 crore in battery storage costs by 2030. This positions such innovations as critical enablers of clean energy transition in India while meeting urbanisation-driven power demands.

Digitisation of Electrical Grids

The push for grid modernisation and renewable energy expansion demands a smarter, more resilient, and more efficient electrical infrastructure. Digital technologies like IoT, AI and predictive maintenance are at the core of this transformation, enabling a shift from traditional grid management to an intelligent, data-driven ecosystem. From dodging unpredictable equipment failure to extended lifespan, a robust automated ecosystem will be crucial to optimising the performance of electrical systems. Moreover, integrating smart grids and decentralised power sources demands adaptive switchgear capable of handling dynamic loads while ensuring seamless connectivity. As a result, the shift toward digital switchgear is becoming essential for modernising the electrical infrastructure and meeting the challenges of India’s increasingly complex energy landscape.

Modern switchgear technologies enhance monitoring and control through digital sensors and advanced communication features. This digital revolution is vital for ensuring grid resilience in the face of natural disasters or cyber threats. It not only enhances operational efficiency but also seamlessly integrates with renewable energy sources, making it essential for modern infrastructure development.

Switchgear integrated with smart grid technologies enhances operational efficiency by enabling automated fault detection, load balancing, and demand response management. For instance, IoT-based switchgear allows utilities to track performance metrics remotely, reducing downtime and optimising energy usage. These innovations improve reliability and facilitate seamless integration with renewable energy sources.

Addressing Challenges in the Sector

Despite its growth potential, the switchgear industry in India faces several significant challenges that could hinder its progress. One of the primary hurdles is regulatory compliance, as manufacturers must adhere to stringent environmental norms while striving to maintain cost-effectiveness. This balancing act is particularly critical in a price-sensitive market like India, where cost optimisation is essential. Additionally, the rapid adoption of advanced technologies necessitates a skilled workforce proficient in digitalisation and smart grid systems, which is currently lacking.

The industry also contends with increasing competition from unorganised sectors and low-quality imports, further complicating the landscape. To navigate these challenges effectively, industry stakeholders must collaborate on policy support, innovation incentives, and skill development programs. Such cooperation can help address compliance, cost management, and workforce training complexities, ultimately driving the sector toward sustainable growth and technological advancement.

The Way Forward

Enhanced safety features, such as arc-flash detection systems and insulated designs, are gaining traction due to growing consumer awareness of electrical hazards. These advancements ensure robust protection and align with the industry’s push toward eco-friendly materials that reduce environmental impact.

Compact designs, particularly Gas-Insulated Switchgear (GIS), are becoming increasingly popular in urban areas with significant space constraints. GIS offers reduced installation time, lower maintenance costs, and enhanced reliability, making it ideal for city buildings and renewable energy projects.

As we progress, the symphony among policymakers, industry leaders, and consumers will be crucial in achieving a greener and more efficient electrical future powered by cutting-edge switchgear technologies.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

A smart hybrid inverter that seamlessly integrates with batteries, solar panels, and the grid gives end-users complete control over their energy sources.

As India accelerates towards achieving its renewable energy goals, reliable solar inverters and grid-connected systems are the backbone of this transformation. These technologies directly influence the reliability and quality of power delivered. At the forefront of this revolution is Vsole Solar Pvt. Ltd., a pioneering solar inverter manufacturer in India known for its cutting-edge R&D and innovative solutions.

The critical role of solar inverters

Solar inverters have a multi-functional role rather than just being a conversion device. While their primary function is to convert DC power generated by solar panels into usable AC power, modern solar inverters are essential for grid synchronisation, power quality management and remote monitoring with analytics. These inverters also ensure load balancing and protection, enhancing system efficiency, stability and reliability. Even the best solar panels cannot function optimally without a high-performance solar inverter. Leveraging this potential, Vsole Solar has engineered a diverse range of single-phase, three-phase and hybrid solar inverters tailored to India’s unique power challenges.

Grid-connected systems

In a grid-connected system, the solar inverter ensures smooth interaction between the solar system and the utility grid. Modern solar inverters have numerous benefits. They enable excess power export through net metering, allowing homeowners and businesses to sell surplus energy. Hybrid inverters provide reliable power backup during grid outages. Additionally, advanced inverters enhance grid stability by minimising harmonic distortion, regulating voltage, and stabilising frequency for consistent power quality.

Vsole’s grid-tied inverters are built with the prime requisites in mind, including offering high efficiency (over 98%), smart connectivity, and compatibility with the latest grid standards.

Enhancing reliability

Reliability is not optional in a country like India, where voltage fluctuations and frequent outages are common; it is essential.

Vsole inverters are designed with advanced MPPT (Maximum Power Point Tracking) algorithms, anti-islanding protection, and robust surge protection. This ensures stable operation during voltage fluctuations, maximises energy harvest even with partial shading, and promotes long system life with reduced maintenance requirements and improved reliability.

One of Vsole’s outstanding innovations is its Smart Hybrid Inverter, which seamlessly integrates with batteries, solar panels, and the grid, giving end-users complete control over their energy sources.

Growing concern about power quality

Power quality directly impacts the lifespan of electrical equipment, system efficiency and safety. Poor power quality can result in equipment damage, data loss and higher energy bills. This is where the smart features of Vsole solar inverters come into play. By actively managing voltage levels, reactive power, harmonics and frequency deviations, Vsole inverters ensure optimal performance across all applications, from residential rooftops to large-scale industrial systems.

Moreover, integrating real-time monitoring and diagnostics allows for proactive maintenance and fault detection, significantly reducing system downtime.

Customisation and innovation

What sets Vsole Solar Pvt. Ltd. apart from others in the industry is its commitment to continuous innovation and customer-centric design. Whether it is creating rugged inverters for coastal climates or compact models for urban rooftops, Vsole offers tailored solutions that meet a wide array of needs. The R&D team works closely with EPC companies, developers, and government agencies to ensure that every product is aligned with evolving industry standards and user expectations.

Reliable power for industrial unit

A recent deployment of Vsole’s Three-Phase On-Grid Inverter at a manufacturing unit highlights the impact of quality inverters. Faced with erratic power supply and rising electricity costs, the unit integrated a 200kW solar system using Vsole inverters.

After six months, electricity bills dropped by 22 percent, inverter-related downtime was eliminated, and machine efficiency improved significantly due to consistently stable voltage output. This is one of many success stories that reflect the trust Vsole has built across sectors.

For more information visit: www.vsolesolar.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The company’s transformers are engineered to withstand higher fault levels and voltage fluctuations, ensuring stable performance of solar and wind-powered grids.

With over 30 years of expertise, Lamco Transformers Pvt. Ltd. has been a trusted name in manufacturing and supplying distribution and power transformers up to 10 MVA in the 33/22/11 kV class. Committed to engineering excellence and sustainability, Lamco plays a vital role in powering the energy future in India. Under the leadership of Amardeep Singh, the company continues to innovate and uphold the highest quality standards. As the energy landscape evolves, Lamco remains at the forefront, delivering reliable solutions that support green growth and infrastructure development. Let us explore the company’s inspiring journey and impact on India’s power sector.

Innovating for renewable energy integration

Lamco is advancing transformer technology to meet renewable energy integration challenges, including dynamic loads and power intermittency. Its transformers are engineered to withstand higher fault levels and voltage fluctuations, ensuring stable solar and wind-powered grid performance. The company also provides compact substation units and custom winding designs that reduce energy losses enhancing transmission efficiency. These innovations make Lamco’s solutions ideal for renewable applications, supporting reliable and sustainable power delivery. Lamco helps utilities and developers optimise their infrastructure for the evolving demands of clean energy integration by focusing on performance, efficiency, and adaptability.

Driving substation digitalisation

Lamco has integrated intelligent monitoring systems into its transformers in response to the national push for smart substations. These advanced systems support predictive maintenance by continuously analysing transformer health and performance data. By detecting potential issues before they escalate, the smart features help minimise unplanned outages, reduce downtime and extend equipment lifespan. This proactive approach ensures a more reliable and uninterrupted power supply. With real-time monitoring and diagnostics, Lamco’s transformers contribute to enhanced grid stability and operational efficiency, aligning with modern power infrastructure goals and reinforcing the commitment to innovation in the energy sector.

Strategic partnerships for scalable sustainability

Lamco has collaborated with companies like WinSun Green Pvt. Ltd., fostering holistic energy solutions through synergistic efforts. Together, it is developing scalable infrastructure where power generation, transmission and monitoring systems function seamlessly. This partnership enables the deployment of hybrid solutions that integrate solar and wind energy supported by advanced transformer technologies. These integrated systems are designed to minimise transmission losses and enhance grid stability. Lamco aims to deliver reliable, efficient and sustainable energy by focusing on rural and industrial regions across India. The joint efforts of both companies support clean energy goals and strengthen the backbone of the country’s evolving power ecosystem.

Lamco Transformers continues to set benchmarks in the Indian power sector, reinforcing its position as a transformer manufacturer and a trusted partner in national progress. The company remains dedicated to supporting energy transition and digital empowerment in India, aligning its innovations with the sector’s evolving needs. With a strong commitment to quality, sustainability and technological advancement, Lamco plays a vital role in shaping a resilient and future-ready power infrastructure across the country.

Authored by : Amardeep Singh, MD & Founder- Lamco Transformers Pvt. Ltd.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Finance Minister in her recent budget has committed 100 GW of nuclear energy by 2047 and immediate provision has been made of ₹20,000 Crore for research and development.

In line with the National Nuclear Energy Mission, the Institute of Chemical Technology (ICT), Mumbai, has announced the launch of the Centre for Energy Science and Technology, a bold and visionary initiative positioning India at the forefront of the global nuclear energy revolution. Drawing upon ICT’s historic strengths in research, innovation, and industry collaboration, the new centre is poised to become a national nucleus for excellence in advanced nuclear energy systems and workforce development.

The announcement was made at a prestigious conclave on ‘Industry-Academia Partnership for Nuclear Science and Technology Development’ at K.V. Auditorium, Institute of Chemical Technology, on 6 May, 2025 in Mumbai. Guest of honour, Dr. Anil Kakodkar, Chancellor, Homi Bhabha National Institute (HBNI) and former chairman, AEC and Secretary, DAE, Govt. of India, addressed the dignitaries present at the conclave.

“The academic community, in its pursuit of independent and original thought, plays a critical role in shaping the future of our nation and the world. It serves as a guiding light for governments as they chart long-term policies and goals. The backbone of any nation’s progress lies in its commitment to research and development, and I commend the Institute of Chemical Technology (ICT) for taking a leadership role in advancing R&D in nuclear energy—an area vital to India’s energy security and sustainable growth.” said Dr. Anil Kakodkar.

With a legacy rooted in scientific achievement and societal impact, ICT now sets its sights on reshaping India’s energy landscape. The Centre will focus on next-generation nuclear technologies including Small Modular Reactors (SMRs), Micro Modular Reactors (MMRs), Hydrogen Generation, and Accelerator Technologies — critical pillars in India’s clean energy transition.

The Centre will:

Speaking on the initiative, Prof. J B Joshi, Chancellor ICT, emphasised, “India’s energy security depends on our ability to innovate boldly and act decisively. ICT’s Centre for Energy Science and Technology will be a beacon of research, talent, and technology, aligned with the national vision for self-reliance and sustainability.”

Through this initiative, ICT reinforces its reputation as a national institution of excellence, and a driving force in India’s development agenda. The Centre will not only transform the country’s nuclear energy capabilities but also cultivate a generation of technologists, researchers, and policy leaders committed to clean, reliable, and secure energy for all.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Serentica Renewables, has signed a Power Supply and Consumption Agreement (PSCA) with INOX Air Products (INOXAP) to supply renewable energy through Inter-State Transmission System (ISTS) project.

Serentica Renewables, has signed a This agreement marks a significant milestone in Serentica’s growth journey as it expands its clean energy solutions beyond state borders, enabling large-scale, multi-location industrial customers to transition to sustainable operations. The 75 MW of hybrid energy will significantly increase INOX Air Products’ renewable energy portfolio, spanning four of its key manufacturing sites in four different states.

Akshay Hiranandani, CEO of Serentica Renewables, said, “This partnership reflects our shared commitment in driving decarbonisation across India’s industrial ecosystem. The scale and inter-state nature of this project showcases our evolving capabilities to deliver firm, reliable, and geographically flexible clean energy to large enterprises. This project represents a major step forward in enabling large industrial customers like INOX to seamlessly transition to sustainable operations across the country.”

Commenting on the partnership, S K Jena, Head – Operations (LASU & Onsite plants), INOX Air Products, said, “With decarbonisation as a priority, we are committed to integrating sustainable practices into every facet of our operations. This agreement with Serentica is a major leap in our decarbonisation journey, as this would enable us to significantly increase the share of renewable energy in our energy consumption mix and get closer to our Net-Zero target. We are excited to reinforce our commitment to clean energy, while ensuring operational excellence across our facilities.”

Serentica’s hybrid renewable solutions integrate wind, solar, and storage assets to ensure 24X7, reliable clean power delivery. Through such partnerships, Serentica continues to accelerate the decarbonisation of hard-to-abate sectors and contribute to India’s broader net-zero ambitions.Power Supply and Consumption Agreement (PSCA) with INOX Air Products (INOXAP). Under this agreement, Serentica will supply 75 MW of hybrid renewable energy to INOXAP – its marquee customer – through Inter-State Transmission System (ISTS) project, enabling competitive tariffs and flexible power usage across multiple locations in different states.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Amplus Solar has been part of the Gentari group since 2023. This integration further brings together Amplus Solar’s deep expertise in the C&I segment with Gentari’s broader utility-scale ambitions.

Clean energy solutions company Gentari announces the integration of its Commercial & Industrial (C&I)-focused platform, Amplus Solar, into the Gentari brand, marking a significant milestone in its journey in India. This strategic move not only reflects a unified brand identity but also signals the consolidation of Gentari’s renewable energy (RE) business in the country.

Amplus Solar has been part of the Gentari group since 2023, contributing significantly to Gentari’s renewables portfolio. This integration further brings together Amplus Solar’s deep expertise in the C&I segment with Gentari’s broader utility-scale ambitions. By operating under a single brand, Gentari will be able to advance stronger alignment across teams and functions, positioning the group to deliver more cohesive and scalable clean energy solutions across both distributed and utility-scale segments.

“This rebrand represents more than just a name change – it marks the next phase of Gentari’s integrated strategy for India as one of our key markets. By bringing together our capabilities in C&I and utility-scale renewables under one roof, we are strengthening our foundation to deliver greater value to our customers. Under a united Gentari brand, we intend to take a more unified and impactful approach in accelerating energy transition in India,” said Sushil Purohit, Chief Executive Officer of Gentari.

As part of this transition, Sharad Pungalia has been appointed as the Gentari Head of India. Sharad, who has been serving as the Chief Executive Officer of Amplus Solar, has been instrumental in scaling Amplus Solar, overseeing the growth of more than 2.4 GW of operational and under-construction distributed energy assets.

With over 20 years of experience in India’s energy sector, Sharad will now lead Gentari’s overall integrated operations in India, spanning its Renewable Energy, Hydrogen, and Green Mobility businesses, reinforcing the company’s commitment to supporting India’s clean energy transition and contributing to Gentari’s global aspirations.

“Sharad’s leadership at Amplus Solar has been instrumental in strengthening Gentari’s foothold in the renewables space. His depth of industry experience and track record in scaling clean energy solutions position him well to further propel our India operations forward. We are confident that under his leadership, we will continue to unlock significant value for our stakeholders,” said Sushil.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

These portable devices, equipped with advanced features such as PC and Bluetooth connectivity, help engineers conduct remote monitoring and testing, greatly enhancing field productivity and response times.

The power infrastructure in India is undergoing a rapid shift to meet the rising energy demands of newly emerging manufacturing hubs propelled by the government’s ‘Make-in-India’ initiative. As industrial growth accelerates, the need for reliable, efficient and technologically advanced power generation, transmission, and distribution systems becomes increasingly vital. In this evolving landscape, modern Testing and Measurement (T&M) instruments play a crucial role in ensuring operational efficiency, safety and performance, particularly within substations.

These portable devices, equipped with advanced features such as PC and Bluetooth connectivity, help engineers conduct remote monitoring and testing, greatly enhancing field productivity and response times.

T&M tools are also instrumental in validating the functionality of digital substations, facilitating accurate real-time monitoring and control. Devices such as power analysers and relay test sets are critical for verifying the precision of protection schemes, thereby improving the reliability and resilience of the overall power system.

Advanced T&M Instruments

The ‘Make-in-India’ initiative by the Central government has encouraged domestic and foreign companies to establish manufacturing units nationwide. This industrial growth demands a significant electricity generation, transmission, and distribution capacity boost. Modern power infrastructure is increasingly adopting advanced testing and measurement instruments to support this expansion. These instruments have PC connectivity, enabling remote monitoring of critical electrical parameters such as voltage, current, frequency and temperature.

Remote monitoring not only enhances operational efficiency but also allows for quicker detection and response to faults. Integrating such technology with intelligent control systems allows modern power stations and substations to be managed more efficiently and reliably. This reduces downtime, improves safety and ensures a stable power supply to meet the growing demands of industrial expansion. Consequently, adopting smart technologies in the power sector is vital in supporting the country’s manufacturing-led economic development.

Enhancing SCADA System Reliability

Supervisory Control and Data Acquisition (SCADA) systems manage operations in digital substations by receiving field signals. These signals are processed by microcontrollers based on pre-defined logic circuits to monitor electrical parameters accurately. To ensure equipment malfunctions cause no errors, SCADA systems rely on precise electronic measurements. However, testing and measurement instruments play a critical role in validating the actual performance and reliability of substation systems. By comparing measured data against expected values, these instruments help confirm the correct functioning of substation components and detect any anomalies early. Integrating digital control and advanced measurement tools ensures safety and performance in modern power systems.

Boosting the Performance of Electrical Systems

Power analysers are crucial in ensuring the reliable operation of electrical systems in substations. These advanced instruments perform various measurements, including AC voltage, AC current, frequency, dips, swells, harmonics, power, energy, power factor, flicker, unbalance, inrush current and voltage transients. By monitoring these parameters, power analysers help detect abnormalities, inefficiencies or potential faults in the system at an early stage. This allows for timely corrective actions, reducing the risk of system failures and enhancing overall operational safety. Their data also aids in verifying system performance and compliance with standards. Through continuous and accurate monitoring, power analysers contribute significantly to digital substations’ optimal functioning, stability and reliability in modern power networks.

*******************************

Authored by: Chandmal Goliya, Managing Director- Kusam Electrical Industries Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The MECO 6363 Battery Capacity Tester operates efficiently in environments ranging from 0°C to 40°C and can handle a maximum input voltage of 50V DC.

The MECO Battery Capacity Tester (Model: 6363) is a compact and reliable device engineered for precise measurement of internal impedance/resistance and open circuit voltage across various secondary battery types, including NiMH, NiCd, Li-ion, Alkaline, and Lead-Acid batteries. It is designed with cutting-edge technology and employs the AC four-terminal method to eliminate lead and contact impedance, ensuring highly accurate results. This tester covers a wide resistance measurement range from 4mΩ to 40Ω, with an impressive resolution of 1μΩ. It can also measure voltages up to 40V, offering a fine resolution of 10mV. The MECO 6363 can operate efficiently in environments ranging from 0°C to 40°C and can handle a maximum input voltage of 50V DC.

Equipped with a dual display, it shows both internal impedance and voltage simultaneously, providing a clear snapshot of the battery’s health. The tester features 99 composite comparator functions, allowing users to preset impedance and voltage thresholds for quick and reliable battery deterioration analysis. Additionally, the unit includes pin-type leads for accurate 4-terminal measurement, enabling easy and stable contact with battery electrodes.

Key features such as memory and read function, manual data logging of up to 999 datasets, and online testing capability without shutting down the battery make it an ideal choice for professionals. The device also includes a PC interface with user-friendly software, facilitating data transfer and analysis on a computer.

With its compact and lightweight design, the MECO 6363 is perfect for on-site and lab-based battery diagnostics. It rates battery conditions as Pass, Warning, or Fail, helping users assess battery life effectively. Overall, this tester is essential for accurate battery capacity evaluation and long-term maintenance.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

According to the National Crime Records Bureau, around one lakh people lost their lives because of electrocution in the last decade alone.

Electrocution, electrical fire and lightning kill 15,000 a year. Also 75000 (approx.) suffer because of these deaths, there is loss of property and assets, dreams of many people associated with deceased shatter. Around 1 lakh people died due to electrocution in the last decade, as per NCRB data.

NCRB data of deaths due to lighting electrocution and short circuit fire 2020-2022

According to the National Crime Records Bureau, around one lakh people lost their lives because of electrocution in the last decade alone. The annual average of fatalities rose to 12,500 per year or 30 fatalities every day.

Causes of electrocution and electrical fire hazard

Electrocution and electrical fires in electrical installations can result from various issues such as over currents caused by overloads or short circuits, presence of harmonics, and earth faults. Electric arcs in cables, loose connections and failure or incorrect selection of protection devices also pose significant risks. Additional causes include improper cable selection, mismatched lighting components, misuse of extension cords for heavy loads, and outdated or damaged equipment. Over voltages, inadequate earthing design, and lack of proper testing or verification further contribute to these hazards.

Role of adequate earthing/grounding

Grounding/earthing means making a connection to the general mass of earth. The use of grounding is so widespread in an electric system that at practically every point in the system from the generators to the consumers’ equipment, earth connections are made.

There are two types grounding:

Equipment and neutral earthing

The objectives of general grounding system

The general grounding system serves multiple critical objectives within a power system. It provides a low-resistance return path for fault currents, ensuring the safety of personnel and protection of equipment. By minimising ground potential rise (GPR) during faults, it prevents hazardous voltage differences with respect to remote ground. It also offers a safe discharge path for power system transients like lightning and over voltages. Additionally, the system ensures uniform potential bonding of conductive objects within a substation, reducing the risk of dangerous potential differences. It further prevents electrostatic charge buildup and allows sufficient fault current flow for proper operation of protection systems.

Unearth system and shock hazard

The main objective of grounding electrical systems is to provide a suitably low resistance path for the discharge of fault current which ultimately provides safety to working personnel and costly installed equipment by providing sufficient current to safety devices.

Electrocution due to high-tension wires

Inadequate clearance: Temporary structures erected for public processions often lack proper planning and supervision, resulting in insufficient clearance between the structures and overhead high-tension wires. Failure to maintain adequate distance increases the risk of accidental contact, especially when structures sway due to wind or crowd movement.

Ignorance and negligence: Organisers and participants may lack awareness about the dangers posed by high-tension wires or fail to recognise the potential hazards associated with erecting structures near them. Ignorance coupled with negligence in adhering to safety guidelines exacerbates the risk of electrocution incidents.

Lack of coordination: Coordination between event organisers, local authorities, and power distribution companies is often inadequate, leading to haphazard planning and implementation of safety measures. Failure to coordinate activities such as route planning, structure placement, and crowd management increases the likelihood of accidents involving high-tension wires.

Encroachment and unauthorised construction: Encroachment on public spaces and unauthorised construction near high-tension wire corridors is a common phenomenon in many Indian cities and towns. Informal settlements, temporary shelters, and makeshift structures often encroach upon the safety buffer zones around high-tension wires, heightening the risk of electrocution during public processions.

Electrical safety at industrial location, generating station and substations

Industries, generating station and substations are critical components of electrical networks, but they also pose significant risks if safety measures are not strictly enforced.

Causes of electrocution and fire in substations include:

High voltage exposure: Industries and substations contain high-voltage equipment that poses a severe risk of electrocution to untrained personnel or trespassers who come into contact with live components.

Equipment failure: Malfunctions or breakdowns of transformers, circuit breakers, and other substation equipment can result in electrical arcs, sparks, and fires.

Lack of proper enclosure: Unprotected or poorly enclosed panels or substations may expose electrical components to environmental factors such as moisture, debris, and wildlife, increasing the risk of failures and fires.

Inadequate security measures: Substations that lack sufficient security measures are vulnerable to unauthorised access, which can lead to tampering, theft, or vandalism that compromises safety.

Insufficient training: Workers at factories or substations must receive comprehensive training on electrical safety protocols and emergency procedures to mitigate risks effectively.

Golden rules to ensure safety

To ensure safety at industrial locations, substations or generating stations, follow these seven golden rules. Begin by thoroughly evaluating the task and conducting an on-site Hazard Identification and Risk Assessment (HIRA). Clearly identify the work location and the specific equipment involved. Apply for a permit to work and review the job details with the team. Disconnect electrical sources and secure them against reconnection using Lockout-Tagout (LOTO) procedures. Always verify the absence of voltage before starting work. Ensure proper earthing of the equipment being serviced. Finally, protect adjacent live parts and exercise extreme caution when working near bare conductors.

Conclusion

Regular maintenance and condition monitoring of electrical equipment are essential to prevent hazards. Routine inspections by qualified electricians ensure early detection of faults. Proper wiring, adherence to safety standards, and the use of overload protection devices like circuit breakers are crucial. Fire safety measures, including smoke alarms and extinguishers, must be in place. Keep electrical setups ventilated and clear of obstructions. Promote awareness about safe practices, especially during rain, waterlogging or public events. Emergency preparedness and lightning protection are vital. By taking these steps, we can reduce risks and ensure safety.

Authored by: Dr. RAJESH KUMAR ARORA Senior Manager Delhi Transco Limited .

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

With currently 18 GW of annual domestic manufacturing capacity for wind turbines and components in India, Indian Wind Turbine Manufacturers Association (IWTMA) pledged to achieve 100 GW of wind power capacity by 2030.

India’s wind energy sector has reaffirmed its commitment to the national renewable energy goals, pledging support to achieve 100 GW of wind power capacity by 2030. At a high-level meeting with the Ministry of New and Renewable Energy (MNRE) recently, the Indian Wind Turbine Manufacturers Association (IWTMA) outlined the industry’s readiness to scale up manufacturing, generate employment, and advance the ‘Make in India’ mission.

“The Indian wind industry is fully aligned with the government’s clean energy vision. We are investing in capacity, technology innovation, and workforce development to achieve 100 GW of wind energy by 2030,” said Aditya Pyasi, CEO, IWTMA. India currently has over 18 GW of annual domestic manufacturing capacity for wind turbines and components. Leading players, including Suzlon, Nordex, Windar, Senvion, Envision, Siemens Gamesa, Flender, ZF Wind Power, Aditya Birla Advanced Materials, Vestas, GE Vernova, and Inox Wind, manufacture critical parts—blades, nacelles, gearboxes, generators, and towers—within the country. This strong value chain supports both domestic demand and India’s emergence as a potential global export hub for wind equipment.