Why India’s digital transition faces unexpected delays?

By EPR Magazine Editorial April 26, 2025 2:32 pm IST

By EPR Magazine Editorial April 26, 2025 2:32 pm IST

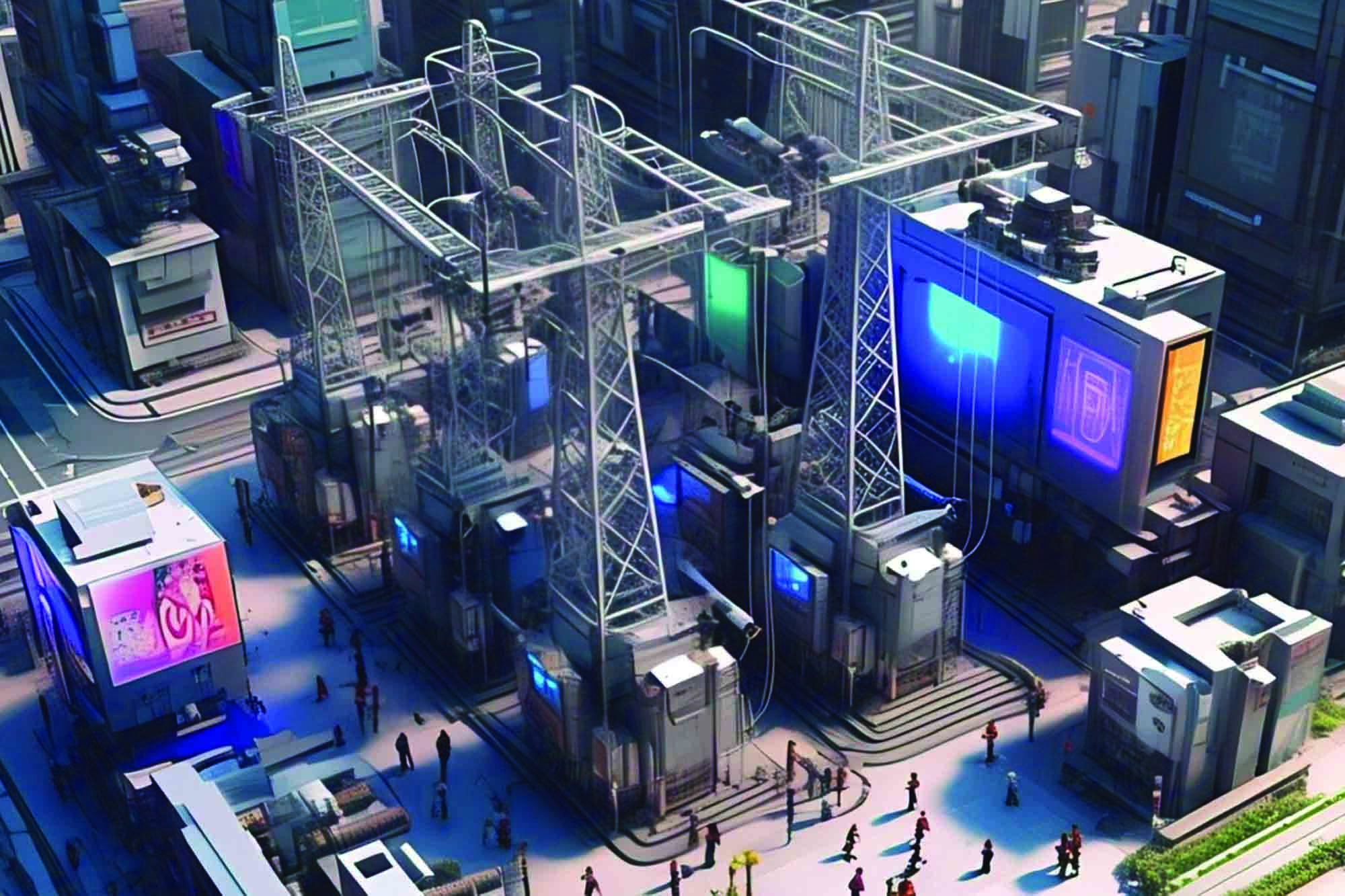

The future of automation and digitalisation holds immense potential for improving transmission network efficiency, reducing operational costs, and enhancing grid stability, ultimately reshaping the country’s power infrastructure.

Implementing digital substations in the power sector has sparked widespread debate, primarily due to technical challenges and the slow pace of integration. While the standard promises enhanced interoperability, communication, and automation within substations, utilities often face difficulties in adapting legacy systems to new digital technologies. One key hurdle is the lack of skilled professionals who are well-versed in both the standards and the intricacies of digital systems. This shortage hinders the smooth transition to a fully digital environment.

Another concern is the gap between the intentions of standardisation and real-world applications. Many utilities face issues in aligning their existing infrastructure with IEC 61850, leading to delays in implementation and increased costs. Additionally, the complexity of integrating protection, control and automation systems from various vendors poses further obstacles.

Industry leaders emphasise the need for greater collaboration among equipment manufacturers, system integrators and utilities to ensure seamless integration. They also advocate for comprehensive training programmes to bridge the skills gap and accelerate adoption. In India’s power sector, the future of automation and digitalisation holds immense potential for improving transmission network efficiency, reducing operational costs and enhancing grid stability, ultimately reshaping the country’s power infrastructure.

Automation in Substations

The world of digital substations has witnessed significant development, yet implementation remains a major bottleneck. As T. Jagat Reddy Director of the Transmission Division from TGTRANSCO, aptly points out, “Technology means it must be like a GIS substation…how the facilities are improved.” His statement reflects the core issue utilities face today — a disconnect between the expected advancements in automation and the practicalities of achieving these advancements. The technology in question, notably IEC 61850, was designed to bring about seamless automation and integration in substations. However, its adoption has not been as smooth as anticipated, largely due to the slow pace of commissioning and the steep learning curve for engineers working on these systems.

Reddy points out the delay in commissioning substations, mentioning, “For a 400 KV substation, I’ll spend about 500 crores of rupees, and for getting it automated, it is taking more than three months…for the supplier to commission it.” The cost and time required to automate substations have proven to be major obstacles. These delays have broader implications for utilities, particularly in managing high-value infrastructure and meeting the increasing demand for power in rapidly growing regions.

Anil Yadav, Management Consulting Principal of Accenture Strategy & Consulting, elaborates on the larger framework of IEC 61850, explaining that it spans multiple stages from substation equipment to communication protocols and control centres. However, he highlights, “The learning curve is not that easy for IEC 61850. It requires expertise.” This expertise is often lacking, with many engineers still being trained on the protocol’s specifics. Furthermore, even though IEC 61850 is intended to be an open standard, Yadav acknowledges that the reality is that many systems are vendor-specific, creating challenges in interoperability and scalability.

Lack of Expertise

The lack of a skilled workforce has been a persistent issue in the power sector. T. Jagat Reddy specifically states the current state of expertise in the field: “None of the manufacturers have expertise…there are only one or two expert people in the country, and many of the people coming for commissioning are temporary employees.” This lack of expertise directly impacts the quality and timeliness of automation processes, which delays getting substations up and running.

This situation is further compounded by the fact that many engineers working on automation systems are often fresh recruits without the necessary experience. As Reddy puts it, “They are sending temporary employees who are not even permanent. How can we go forward with such a situation?” This reliance on inexperienced personnel for critical projects is a significant risk, particularly when dealing with complex systems crucial to the smooth operation of power transmission networks.

Harshal Vyas, Head of Corporate Strategy and Communications at Bajel Projects Limited, shares a similar sentiment: “We dominate two or three global players or local players that play in a specific niche.” He also emphasises the challenge of the lack of scale in manufacturing, which affects the timely availability of automation systems and components. Vyas highlights the role of third-party system integrators who often face challenges in communicating and integrating different vendor systems. The lack of a unified approach to system integration combined with the skill gap has made the rollout of digital substations far more difficult than it should be.

Retrofits and ScalingDespite the challenges highlighted by the experts, many utilities are finding ways to manage the adoption of digital technology through retrofitting. Retrofits allow for integrating new systems into existing infrastructure with minimal disruption. Pramod Mishra, Additional Vice President of BRPL (BSES Rajdhani Power Limited), discusses how retrofitting has been a cost-effective approach to modernisation, stating, “If you can deliver the expected result with little additional cost without replacing the existing equipment, it helps…retrofit solutions can come in handy.”

However, Pramod also acknowledges the limitations of retrofitting, particularly regarding sustainability. Retrofitting may not provide long-term solutions for replacing legacy equipment or ensuring the future-proofing of systems. He uses the example of the 15,000 remote monitoring units (RMUs) in their network, noting that retrofitting with communicable features can help improve fault detection and isolation, but this comes with its challenges in terms of cost and scalability.

The challenge of scaling up digital substation technology remains a critical issue. According to Anil Yadav, scaling issues arise when the initial design and planning of the system are not done with scalability in mind. “If we are facing problems in scaling, it means the system has not been designed right from the start,” he notes. This observation is critical because it highlights that failing to plan adequately for future expansion leads to difficulties when integrating new technologies or scaling existing systems. The underlying issue is that many utilities are not thinking far ahead when designing their digital infrastructure, leading to gaps in their ability to implement upgrades efficiently.

Vendor-Specific Solutions

A key issue is the challenge posed by vendor-specific solutions. Even though IEC 61850 was designed as an open standard, the reality is that many suppliers have not fully embraced this approach. T. Jagat Reddy is particularly vocal, stating, “When I buy a substation automation system from one company, I must be able to plug in components from another company if it is an open protocol system.” The inability to seamlessly integrate systems from different vendors results in operational difficulties and increased costs for utilities, who are often forced to deal with proprietary systems that limit their flexibility.

Open, interoperable systems are a core principle that needs to be emphasised moving forward. For digital substations to reach their full potential, systems need to be more adaptable, enabling utilities to switch between suppliers and integrate new technologies without experiencing significant downtime or operational disruption. This is where the need for standardisation and adherence to open protocols becomes critical. Harshal Vyas concurs with this sentiment, noting that the future will require “system integrators who can communicate between different systems,” ensuring that disparate technologies can work together efficiently.

Road Ahead

Looking ahead, the future of digital substations appears promising, but significant challenges remain. As the global demand for electricity increases, the need for more efficient, reliable and automated transmission systems becomes more critical. T. Jagat Reddy points out that by 2030, the country’s transmission capacity must be increased to 750 gigawatts, with an 80 percent increase in substation capacity. Achieving these ambitious goals will require a comprehensive embrace of digital technologies and innovations, allowing greater flexibility and adaptability in power transmission.

In this regard, the government has a role in supporting the transition to digital substations. As Harshal Vyas suggests, there should be long-term plans from the OEM side that ease the burden on utilities, potentially through financial incentives or subsidies for digital infrastructure upgrades. Pramod also highlights that the push for modernisation comes from the government with initiatives like the Resource Adequacy Plan, which focuses on building resilient networks that can withstand future challenges.

Ultimately, the adoption of digital substations will require technological advancements and a cultural shift within utilities and their suppliers. The importance of training, building expertise, and fostering collaboration between system integrators, vendors, and utilities cannot be overstated. Only by addressing these key issues can the full potential of digital substations be realised.

The journey toward fully automated and digital substations is long, but it is clear that the future lies in embracing these innovations. As T. Jagat Reddy aptly sums up, “Technology evolution is the key to meeting the growing demands of the future.” The challenges of expertise gaps, vendor-specific solutions, and retrofitting must be addressed head-on. Utilities can move closer to a future where digital substations become the norm rather than the exception by fostering greater collaboration, standardisation and support for scaling. The time to act is now as the power transmission industry braces for unprecedented growth and transformation.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.