Lithium Battery and Critical Minerals – Why we should get serious about mining critical minerals for clean energy

By EPR Magazine Editorial September 5, 2023 11:30 am IST

By EPR Magazine Editorial September 5, 2023 11:30 am IST

Rare earth mining’s competitive scarcity triggers geopolitical tensions, escalating with environmental concerns and clean tech demand. Recycling, transparency, and a circular economy are vital. India should prioritise sustainable mining for clean energy independence

The mining of rare earth elements is perceived as a “zero-sum game” due to the limited global reserves and intense competition for these critical minerals. With relatively scarce deposits and an uneven distribution worldwide, countries vie for control over the resource, leading to geopolitical tensions. Furthermore, environmental degradation caused by mining, coupled with the increasing demand for rare earth elements in clean energy technologies and electronics, exacerbates the competition. The complexities of extraction and processing, along with the potential market control by a few dominant players, add to the challenge of ensuring sustainable access to these essential resources while considering environmental and social impacts.

Role of critical rare-earth minerals in clean energy

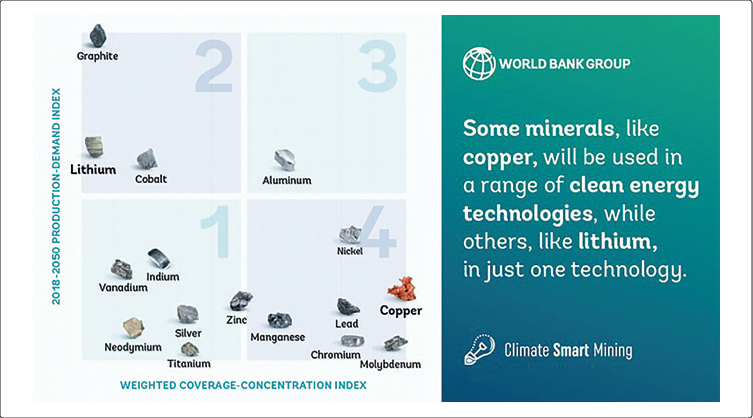

Critical minerals play a crucial role in clean energy products, facilitating the transition to sustainable technologies (see Figure 1). Rare earth elements like neodymium, dysprosium, and praseodymium are vital for wind turbines and electric vehicle motors. Solar panels rely on tellurium, indium, and gallium. Lithium-ion batteries, essential for energy storage, contain lithium, cobalt, and nickel. Energy-efficient lighting incorporates terbium, europium, and yttrium. Fuel cells utilise yttrium and gadolinium. Hydrogen production and storage technologies use lanthanum and cerium. Securing a stable supply of these critical minerals is pivotal for advancing clean energy and combating climate change.

Essential elements and components of Lithium-ion batteries

The primary components of a standard lithium-ion battery are lithium, cobalt, nickel, manganese, and graphite. These elements are essential for the battery’s cathode and anode materials, electrolyte, and separator. Keep in mind that the usage of specific critical minerals can vary depending on the technology and its specific design. Moreover, ongoing research and advancements may lead to changes in the materials used in these products.

Major recyclers of critical minerals include companies like Umicore (Belgium), Solvay (Belgium), and Mitsubishi Materials (Japan). These companies have established advanced technologies and processes to recover critical minerals from various products, including electronic waste, magnets, and industrial scrap. Additionally, some countries, such as Japan and South Korea, have implemented strategic initiatives to promote critical mineral recycling due to their limited domestic reserves and the importance of these elements in critical technologies. The recycling efforts by these major players contribute to resource conservation, reduce dependency on primary mining, and support sustainable supply chains.

Sustainability, tracability and recycling capabilities and applications

India’s rare earth recycling industry is still in its nascent stages compared to other countries. India’s recycling efforts primarily focus on electronic waste and certain industrial processes, and the critical mineral recycling infrastructure is limited at this time.

One effective way to ensure the traceability and sustainability of critical minerals used in lithium batteries throughout their lifecycle is the concept of a battery passport (from the Global Battery Alliance, Figure 2). A battery passport, in a broader context, refers to a standardised documentation system that tracks essential information about batteries, such as their composition, origin, manufacturing process, and environmental impact. It is intended to provide transparency to consumers and stakeholders regarding the environmental and social aspects of the batteries they use, promoting responsible and sustainable practices.

Building a circular economy for rare-earth elements involves developing strategies to reduce dependency on primary mining and enhance recycling and reusing practices. This entails improving the design of products to facilitate the easy extraction and recovery of rare-earth elements, establishing efficient recycling systems, and investing in advanced separation and purification technologies. Additionally, promoting international collaboration and standardising recycling processes can optimise resource recovery. Implementing responsible sourcing and supply chain transparency is crucial to ensuring sustainable practices. A circular economy for rare-earth elements can mitigate environmental impacts, secure supply chains, and promote a more sustainable and resilient approach to these critical resources.

Prioritising transperancy in mining activities for Lithium batteries

India should prioritise mining critical minerals for clean energy due to their vital role in lithium batteries and other clean energy technologies. Lithium-ion batteries, crucial for energy storage in electric vehicles and renewable energy systems, contain essential elements like lithium, cobalt, and nickel. India’s demand for clean energy is rapidly growing, and securing a steady supply of these critical minerals domestically can reduce dependence on imports, enhance energy security, and promote sustainable manufacturing. By investing in responsible mining practices and fostering a circular economy for critical minerals, India can support the clean energy transition, combat climate change, and strengthen its position as a leader in the global green energy revolution.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.