Thermal imaging and monitoring increasing reliability in substations

By EPR Magazine Editorial April 26, 2025 2:59 pm IST

By EPR Magazine Editorial April 26, 2025 2:59 pm IST

Predictive maintenance tools have emerged as essential solutions enabling proactive detection of potential issues before they lead to costly failures.

In the rapidly advancing electrical infrastructure landscape, ensuring reliability, efficiency, and safety is more critical than ever. With growing power demands and ageing assets, utilities face increasing pressure to maintain uninterrupted service. Predictive maintenance tools have emerged as essential solutions enabling proactive detection of potential issues before they lead to costly failures. Among these tools, thermal imaging cameras and environmental monitoring instruments stand out for their effectiveness and versatility.

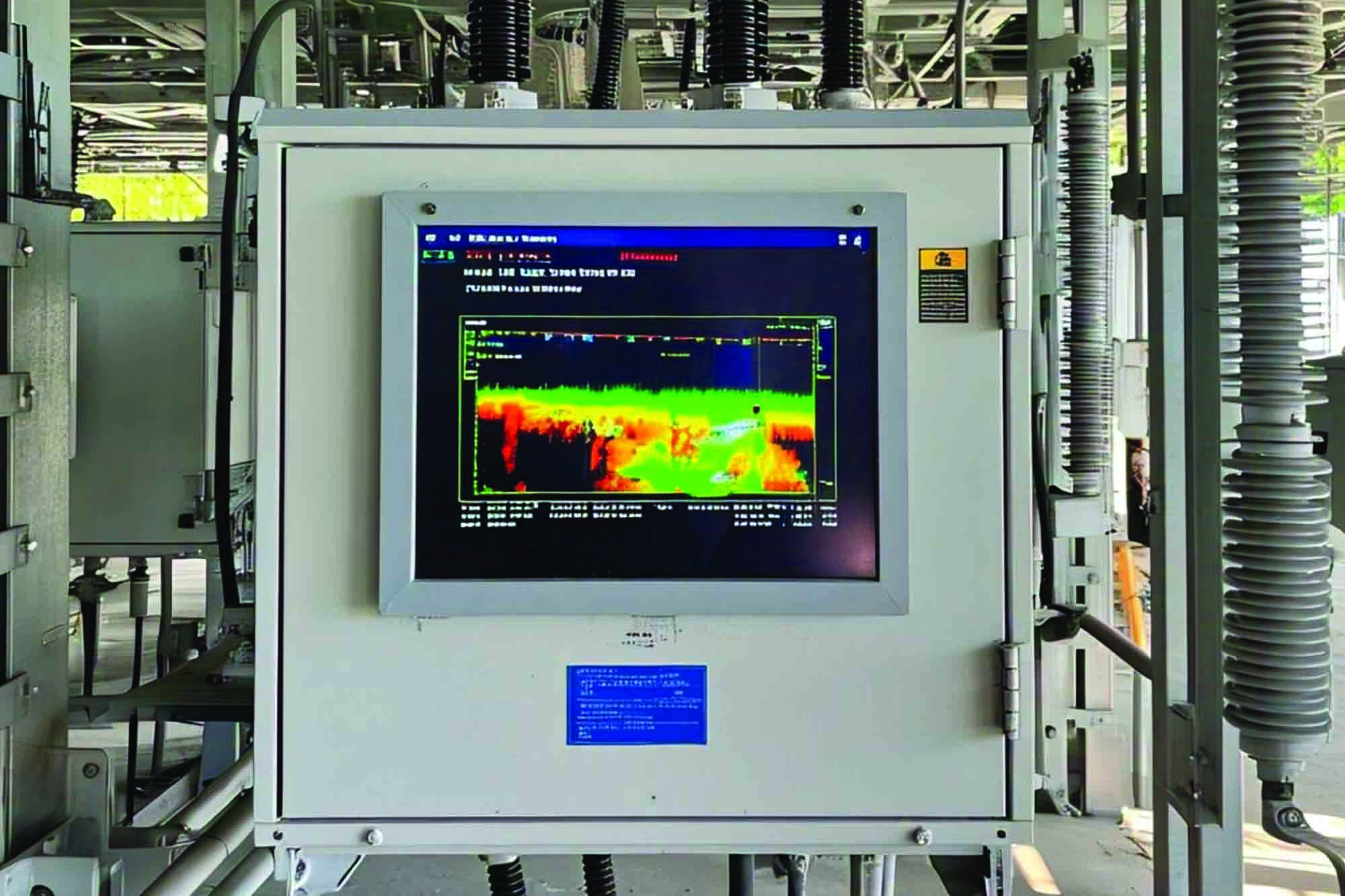

Thermal imaging allows operators to visualise heat patterns and identify anomalies in equipment such as transformers, circuit breakers, and insulators. This early detection of overheating components can prevent breakdowns, extend asset lifespans, and reduce maintenance costs. Meanwhile, environmental monitoring devices track factors like humidity, temperature, and gas levels, providing real-time insights into substation conditions.

Together, these technologies play a pivotal role in the evolution of smart substations and digital power systems. By integrating thermal and environmental data with digital platforms, utilities gain deeper visibility into asset health, enabling data-driven decisions and remote diagnostics. This shift enhances operational efficiency and boosts grid resilience and safety. As the industry embraces modernisation, thermal imaging and environmental monitoring are proving indispensable to building a more reliable and intelligent power infrastructure. Let us analyse the changing shift in the sector with industry experts.

Role of Thermal Imaging in Fault Prevention

Thermal imaging is critical in fault prevention as it enables the real-time detection of temperature anomalies in electrical and mechanical systems. Identifying hotspots or irregular heat patterns helps detect issues like loose connections, overloaded circuits or failing components before they lead to equipment failure. This non-contact, non-invasive method enhances safety and operational efficiency, allowing for early intervention and timely maintenance. Widely used in power utilities, manufacturing and critical infrastructure, thermal imaging reduces downtime, prevents costly repairs and extends the lifespan of equipment. Its accuracy and speed make it essential in modern predictive maintenance strategies.

“Thermal anomalies often precede critical equipment failures in the electrical and power sectors,” explains Kalidas Bhangare, Managing Director of Testo India. “Testo’s thermal imaging cameras provide precise non-contact temperature measurements. Early detection through thermal imaging allows maintenance teams to intervene before faults escalate.” The company’s thermal imaging technology offers high-resolution imagery and advanced analytics, making it indispensable during routine inspections. By enabling accurate diagnostics without interrupting operations, thermal imaging improves operational safety, asset longevity and energy efficiency.

Martin Lv, Product Manager at Raythink Technology Co. Ltd., emphasises the science behind their approach: “The thermal imaging technology of Raythink utilises infrared radiation principles for non-contact surface temperature measurement. It offers a wide detection range, rapid response and high accuracy.” Raythink’s technology is tailored for continuous substation monitoring, detecting early indicators of issues like insulation degradation or short circuits. Critical components under surveillance include transformers, circuit breakers, GIS equipment, disconnectors, voltage/current transformers, surge arresters, capacitors, reactors, busbars, insulators, bushings, cables and switchgear.

Real-Time Monitoring

Real-time substation monitoring enhances operational efficiency, safety, and reliability by continuously tracking equipment conditions and environmental parameters. Using advanced sensors and communication technologies, critical assets such as transformers, circuit breakers and switchgear are monitored for temperature, voltage, current and other vital metrics. This allows for early detection of anomalies, enabling predictive maintenance and minimising unplanned outages. Integration with SCADA systems provides operators with immediate alerts and actionable insights, improving response time and decision-making. Real-time monitoring supports a proactive maintenance strategy, reduces downtime, and extends equipment lifespan, all of which are vital in modernising power grid infrastructure.

Martin says, “Our infrared thermal imagers enable early detection of potential failures in critical equipment such as transformers and circuit breakers. For transformers, infrared thermal imaging identifies defects in components like the main body, conservator tank, bushings, coolers and control circuits.” These non-contact diagnostic tools provide valuable insights into abnormal heat patterns. For instance, elevated temperatures on transformer bolts may indicate eddy currents from magnetic leakage. Overheating at bushing connections often points to poor electrical contact, while localised spikes on bushings could be due to surface contamination or excessive dielectric loss.

Overcoming Implementation Challenges

Integrating thermal imaging cameras into substations presents challenges such as environmental interference, high installation costs and system integration complexities. Substations often operate in harsh conditions, requiring durable weather-resistant cameras. Accurate data interpretation demands specialised software and skilled personnel. Additionally, retrofitting existing infrastructure can disrupt operations and incur significant expenses. Compatibility with existing SCADA systems is also critical to ensure seamless data flow and real-time monitoring. Overcoming these hurdles requires strategic planning, investment in robust technology, and staff training. This includes long-term benefits, enhanced predictive maintenance, improved safety, and reduced downtime, ultimately making the investment worthwhile despite initial implementation barriers.

“Surface reflection interference from high-reflectivity materials like metal enclosures can lead to misdiagnosis,” Martin from Raythink notes. “Raythink mitigates this with polarisation filters and image fusion algorithms,” he says. Retrofitting older substations also presents hurdles due to their reliance on wired temperature monitoring systems. “Traditional setups often require extensive cabling or structural changes, which can be costly,” says Martin. “We address this with wireless transmission technology and a modular design, reducing installation complexity and supporting non-invasive upgrades,” he adds.

Environmental Monitoring for Substation LongevityThermal imaging detects equipment-specific issues by identifying temperature anomalies that signal potential faults or failures. This allows for targeted maintenance and improved operational safety. In contrast, environmental monitoring provides a broader view of system health by tracking factors like humidity, air quality and ambient temperature, which can impact equipment performance and longevity. Together, these technologies offer a comprehensive approach—thermal imaging ensures individual components function properly while environmental monitoring safeguards the overall system environment and operational stability.

“Environmental conditions directly influence the reliability and longevity of substation equipment,” says Kalidas Bhangare. “Testo’s advanced monitoring instruments keep parameters like temperature, humidity and differential pressure within optimal limits,” he explains. These instruments provide continuous, real-time feedback, alerting technicians to threats such as excessive humidity, which can cause condensation or corrosion in high-voltage systems. Improper temperature control may result in overheating or performance issues in sensitive control equipment. “Our data loggers and real-time monitoring systems provide technicians with precise, reliable insights,” Kalidas continues. “Instruments like sound and lux meters also help maintain safe and comfortable working environments.” This data supports predictive maintenance strategies, reduces unplanned downtime, and enhances system performance.

SCADA System Reliability

SCADA (Supervisory Control and Data Acquisition) system reliability is critical for ensuring continuous monitoring and control of industrial processes. High reliability minimises downtime, enhancing operational efficiency and ensuring safety across systems like power grids, water treatment and manufacturing. It depends on robust hardware, secure communication networks and effective software. Regular maintenance and cybersecurity measures also play vital roles. Reliable SCADA systems support timely decision-making, reduce operational risks and enable real-time responses to system anomalies or failures. Thermal imaging and environmental monitoring gain further utility when integrated with substation automation and SCADA systems. “Raythink’s full range of hardware products, from detectors to integrated systems, supports multiple industry-standard protocols, including ONVIF, GB/T 28181, MODBUS, and MQTT,” Martin explains. “This ensures seamless integration,” he adds.

Chandmal Goliya, Managing Director of Kusam Electrical Industries Ltd, underscores the importance of measurement tools in SCADA environments. “SCADA systems manage operations by receiving signals from the field. Microcontrollers process these to monitor electrical parameters accurately.” Measurement instruments verify the accuracy of these signals. “By comparing actual performance to expected values, these tools detect anomalies early and ensure substation components function correctly,” Chandmal highlights. Advanced measurement tools are critical in maintaining the safety and reliability of digital substations, ensuring the systems perform as intended under a wide range of conditions.

Power Analysers

Complementing thermal and environmental monitoring, power analysers play a crucial role in substations by providing real-time insights into electrical parameters such as voltage, current, frequency and power quality. These devices help detect anomalies, imbalances and inefficiencies in the power system, enabling predictive maintenance and reducing the risk of equipment failure. By monitoring energy flow and system performance, power analysers support the efficient and reliable operation of substations, ensuring optimal energy distribution and enhancing grid stability and safety.

“These instruments measure parameters like voltage, current, frequency, dips, swells, harmonics, power, energy, power factor, flicker and inrush current,” Chandmal highlights. By monitoring these metrics, engineers can detect abnormalities and inefficiencies, enabling timely interventions that enhance operational safety and stability. Power analysers also help ensure compliance with industry standards and verify system performance. “Through continuous and accurate monitoring, power analysers contribute significantly to the optimal functioning of modern digital substations,” Chandmal adds.

Equipping Engineers with Handheld Devices

Handheld devices empower engineers with quick on-site diagnostics, facilitating fast decision-making and efficient fault detection. These devices provide real-time monitoring, allowing engineers to assess equipment conditions, detect anomalies, and take immediate corrective actions. This reduces downtime, enhances operational safety, and improves overall efficiency. By integrating advanced technologies, handheld devices streamline the process of identifying issues, making them invaluable tools for engineers in power utilities.

“Electrical and HVAC engineers operate in fast-paced environments, often needing to act swiftly. Our handheld measurement devices deliver speed, accuracy and convenience,” Kalidas Bhangare explains. These devices measure key parameters such as current, voltage, temperature, humidity and airflow. HVAC systems also capture data like superheating, subcooling and refrigerant pressures to optimise performance and energy efficiency. “Our instruments feature high-resolution sensors and smart connectivity via the Testo Smart App. Engineers can view, save and share data in real-time, improving collaboration between teams,” Kalidas highlights. These devices’ portability, durability, and accuracy make them essential tools for turning diagnostics into actionable solutions.

Hence, we can say that integrating thermal imaging, environmental monitoring, SCADA systems and handheld diagnostic tools form the backbone of predictive maintenance. These technologies enhance safety and reliability and drive energy efficiency and operational cost savings. Companies like Testo, Raythink, and Kusam Electrical Industries are at the forefront of this transformation. Through advanced diagnostics, real-time monitoring and intelligent data integration they are enabling power utilities to meet the demands of today while preparing for the challenges of tomorrow.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.