Don’t Change Oil, Keep it Clean

By EPR Magazine Editorial November 27, 2017 10:52 am IST

By EPR Magazine Editorial November 27, 2017 10:52 am IST

At least 75 per cent of equipment failures occur due to lube oil contamination. So, in order to eliminate equipment uncertainty it is very important that we proactively maintain the lube oil quality.

Contaminants may enter any oil system either through the reservoir air breathers; or maybe present from the start-up of the system; or be introduced into the system through maintenance and top ups of oil. However, major concerns are particles produced through oil oxidation—which is an ongoing process and the main cause for all oil changes.

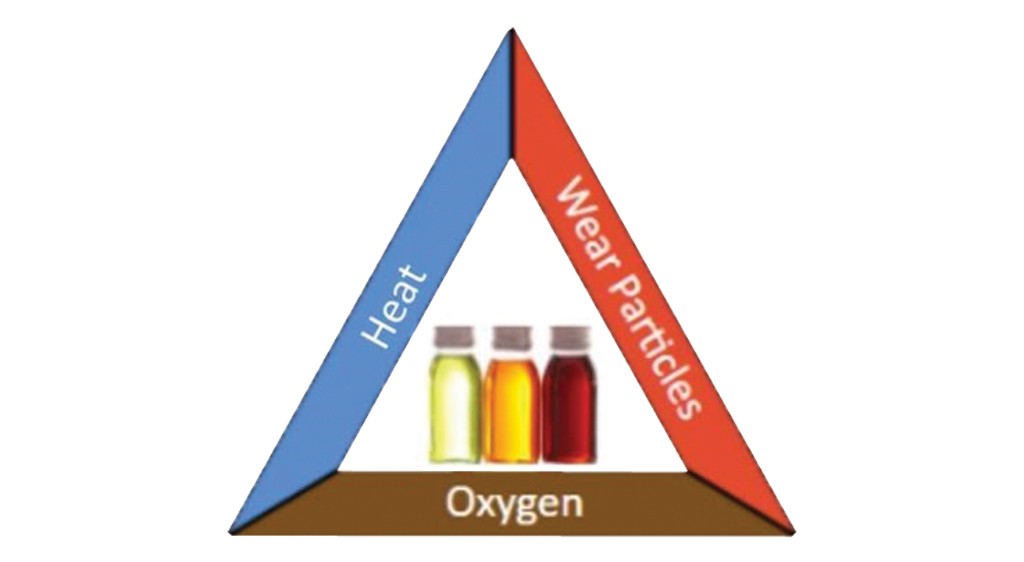

Oil oxidation is the nemesis of lube oil and ultimately leads to the formation of varnish. This in turn degrades the oil and critical components of any equipment.

Oil Oxidation = Oxygen + Heat + Wear Particles

Heat or oxygen cannot be prevented from acting on the system but if wear particles are effectively removed, oil oxidation can certainly be prevented.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.