Partial discharge testing of power transformer

By EPR Magazine Editorial November 13, 2018 3:40 pm IST

By EPR Magazine Editorial November 13, 2018 3:40 pm IST

The need to manage an electrical power system asset economically and keep a check on the quality criteria is raising the issue of applying quality control and diagnostic techniques to electrical network components so as to increase their reliability and reduce direct and indirect costs. Such techniques form the basis for an efficient and reliable asset management, as they can ultimately reduce the failure rate. Power transformers are one of the most expensive components of the electrical power system. These transformers may experience failures which may be due to insulation failure caused by internal discharges in the insulation itself or high quantity of dissolved gases or loose connections which may lead to corona and surface discharges.

Partial discharge- A tool for condition-based monitoring

Partial discharge (PD) measurement and analysis is one of the major tools to detect any defect or damage and identify any weak spot which may lead to insulation failure. This technology, however, is not so popular earlier, but is now gaining popularity as one of the effective techniques to carry out condition-based monitoring (CBM) and risk analysis. In reality, the degree of harmfulness associated with partial discharges can be assessed only if the kind of source generating them can be identified. For example, large partial discharges happening at the surface of insulation system are generally less harmful than low amplitude partial discharges occurring in cavities or voids inside the insulation. In addition to this, most of the time, partial discharges are mistaken for noise and disturbances. Hence, a misinterpretation of data acquired during PD measurement may lead to proactive maintenance. Moreover, PDs themselves might not be the fastest cause of insulation degradation, nor they cover the diagnosis of all insulation defects.

It can be summarised that, when PDs are the most suitable diagnostic property for a certain insulation system, their identification as well as localisation becomes necessary because only the correct attribution of the acquired PD pulses to their source(s) will allow a consistent evaluation of their harmfulness arising out of the insulation defects. Therefore, measurement systems that provide advanced tools for the identification of PD, can contribute towards the optimisation of CBM procedures by increasing the reliability and efficiency at a reduced cost.

ALTANOVA is one of the leading companies in the field of condition-based monitoring (CBM) and diagnostics of electrical apparatus. ALTANOVA has its roots in two strong and long experienced companies well set in the market of testing and monitoring: ISA and TECHIMP.

Partial discharge

As per IEC 60270, Partial discharge is a localised electrical discharge that only partially bridges the insulation between conductors and which can/cannot occur adjacent to a conductor. PDs normally develop in air gaps or on insulation surfaces, due to defects in the insulation system. Because PDs are correlated to insulation ageing, they are the cause and effect of insulation degradation.

Types of partial discharge

Internal PD : It can occur inside the insulating system defect, such as voids or contaminants, and can eventually trigger electrical treeing.Surface PD: It can occur in surfaces of insulating materials if the electric field is high, and can provoke insulation tracking. Corona PD: It is originated in correspondence of sharp tips or protrusions or in the HV connections, normally it is not harmful.

Diagnostic Procedures

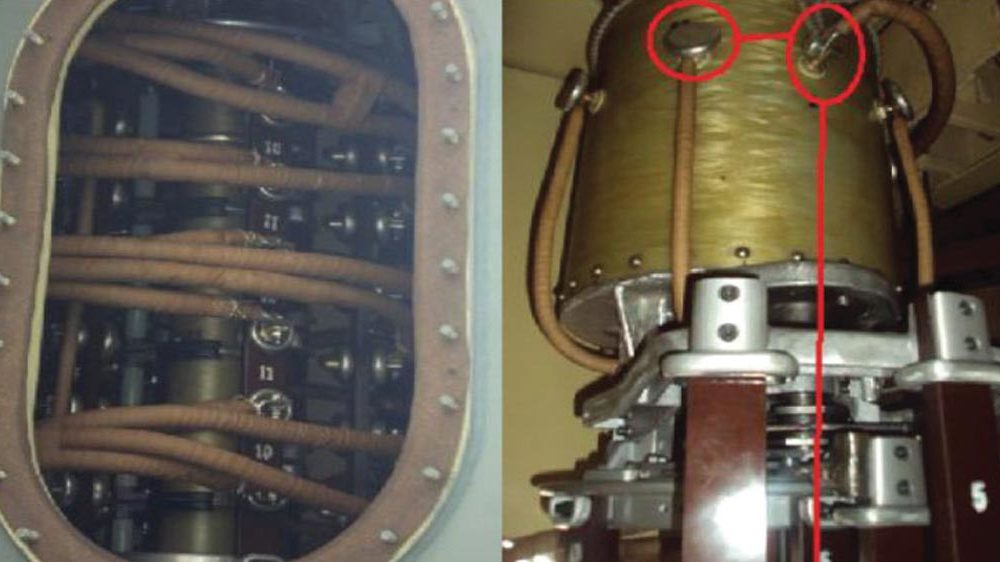

PD recognition is the prerequisite for correct diagnosis. The measurement on the equipment under test (EUT) is done by using sensors such as high frequency current transformer (HFTCT) on the transformer tank ground and by using transient Earth voltage (TEV) sensor on the transformer tank. These sensors send the signal to the system which is recorded by the PC installed with the TECHIMP software.

Innovative Technology of TECHIMP

The most crucial part in PD testing is the interpretation of the acquired data. Any misinterpretation of PD data may lead to dangerous results. With the advanced and patented technology of TECHIMP-Altanova group, it is now possible to segregate noise and disturbances from partial discharges during and after the acquisition. The software helps in recording the Phase Resolved Partial Discharge (PRPD) pattern. Thanks to the patented T-F map technology of TECHIMP, which performs the Fast Fourier Transformation (FFT) of PRPD pattern and gives the T-F mapping. The T-F mapping helps in visualising different clusters which are having a distinct frequency range. On the basis of the frequency range, shape of the sub-pattern, amplitude of the waveforms, the sub-patterns are classified into noise, disturbance or partial discharge. T-F mapping also helps in noise rejection during the PD data acquistion. The recorded data is then further analysed for the identification and localisation of PD. Based on the diagnosis, corrective as well as preventive actions are recommended for the tested electrical asset(s).

On-site measurements and data interpretation

Areva T & D make power transformer having rating 230 kV/10.5 kV/ 140 MVA was tested while in operation. TEV and HFCT sensors were used for the acquisition of PD data using TECHIMP Acquistion Unit (Model: PDBase II) having 4 PD channels (extended upto 7 PD channels). The same unit can be used for off-line testing of transformers or other electrcial assets.

The recorded data was analysed with the PD Processing Software and it was found that the transformer was having PD activities in the form of corona discharges. It was recommended to check for any loose HV connections and any sharp point in connections and also clean the cable termination and diverter switch. During the inspection of transfomer by the customer after testing (as recommended by TECHIMP), it was found that the diverter switch had loose connections which was giving corona discharges.

It can be said that the innovative technology allowing the separation and identification of partial discharges can play an important role in the condition-based monitoring of power transformer.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.