Real time monitoring for distribution efficiency and transformer analysis

By EPR Magazine Editorial July 5, 2019 12:04 pm IST

By EPR Magazine Editorial July 5, 2019 12:04 pm IST

India has one of the largest electrical power distribution network in the world, connecting the consumer base of around 200 million, having 400 GW of connected load. The Power network in India, distributed 1142 billion units generated in 2018-19 (till Feb19), with the current reported ATC losses of approximately 19.69 per cent, which is quiet high, compared to the 9 per cent of developed countries.

The losses incurred, are due to poor administrative management, inadequately maintained distribution network, inadequate planning, leading to inefficiency in networks and electrical, and ageing of infrastructure. Transformer in the distribution network are the key assets, and the estimated losses in the transformers is estimated to be at approximately 4 per cent which amounts to `200 billion, as against the standard acceptable losses of < 1percent.

The primary reason attributed to the technical losses in a distribution are due to inadequate planning, that often leads to addition overloading the transformer due excess allocation of new customers, thereby, causing inefficiency, thus generating more losses, in the form of heat, leading temperature overhaul in the transformer which further invite the losses. Secondly, the operating condition of a transformer, when subjected to unbalanced loading condition causes flow of circulating current in the winding.

The transformer for distribution network, are designed with a service life of 25 years. Transformers are continuously subjected to environmental and operation stress, which impact their performances. Inadequate maintenance, lower the transformer’s capacity, amounting to increased losses, so as to accelerate ageing of transformer, thereby reduces the service life.

Transformer IoT multi-monitor

Motwane has introduced Transformer IoT Multi Monitor that records and monitor the vital parameters, and analyse them, for estimating the health of the transformer in Distribution Network. Monitoring of the transformer in the distribution network requires real-time data on its’ health parameters and trends of this data is made possible by deploying cost effective sensors, hardware to integrate, perform computation and a reliable communication network to access the data effectively and the infrastructure to store and compute the large volume of data. Advancements in computer processing technology and storage capacity availability are enabling factors in the monitoring of distribution transformers.

The vital parameters which can be remotely monitored, stored and analysed for estimating the health of the transformer in Distribution Network are, load current of the three phases, oil temperature, oil level in the conservator tank, ambient temperature, humidity.

This data can be analysed for historical trends, correlations, and the predictions can be made using statistical tools. Based on the above parameters, we can identify unbalance in the load currents, overload condition, oil temperature fluctuation with load currents, and leakage of the transformer oil.

Further to these the following important parameters can be inferred and alerts can be generated when any parameter crosses a limit value.

Estimated winding temperature

The power transformers in the distribution substation typically have the sensors like, buchholz (gas operated relay), oil level gauge, pressure relief valve, oil temperature gauge, which are used for status alerts and safety protection.

The above sensors are calibrated to operate when the value of the parameter measured breaches the set point.

The Buchholz and Oil temperature gauge has an early set point which is used to activate the alarm and annunciation. The next set point is used to send the trip command to the switchgear to isolate the transformer from the network.

The proximity to the control room makes it feasible to connect these sensors to the control room and monitor the substation transformer.

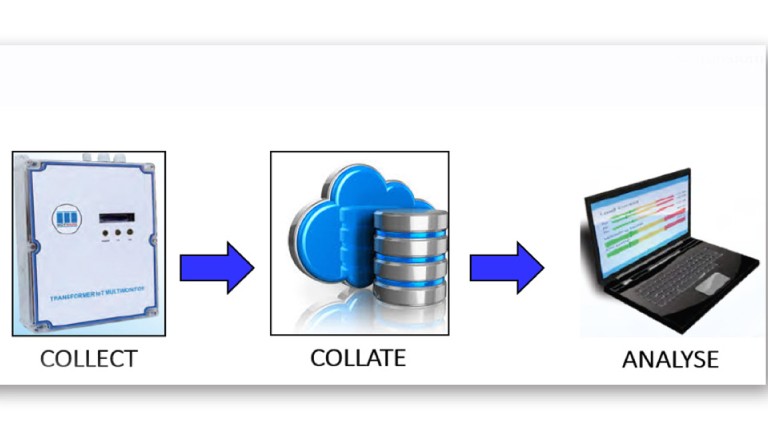

Solution architecture

The breakthrough in cloud technologies for storage, processing and analysing large volume of data along with very significant enhancement in edge computing capabilities enabling to hardware to capture the sensors data and process in real time and be able present it in meaning full structure to a Middle ware gateways for seamless flow of the data to cloud hosted application would make it possible to monitoring store and do analysis of large number of scattered assets like Distribution transformer in a very cost effective manner.

Advantage of real-time monitoring

The real-time transformer monitoring solution, is the use of available computing and sensing technologies, to help digititalise and ageing infrastructure network for enhancing the efficiency and reliability of power through the network. It can assist in:

Article By:

Achal Trivedi,

Project Head,

trivedi.achal@motwane.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.