Enhance your utility’s asset management with HIKMICRO thermal imaging

By EPR Magazine Editorial May 27, 2024 6:02 pm IST

By EPR Magazine Editorial May 27, 2024 6:02 pm IST

Proactive inspections prevent costly equipment failures, ensuring reliability and significant cost savings for utilities.

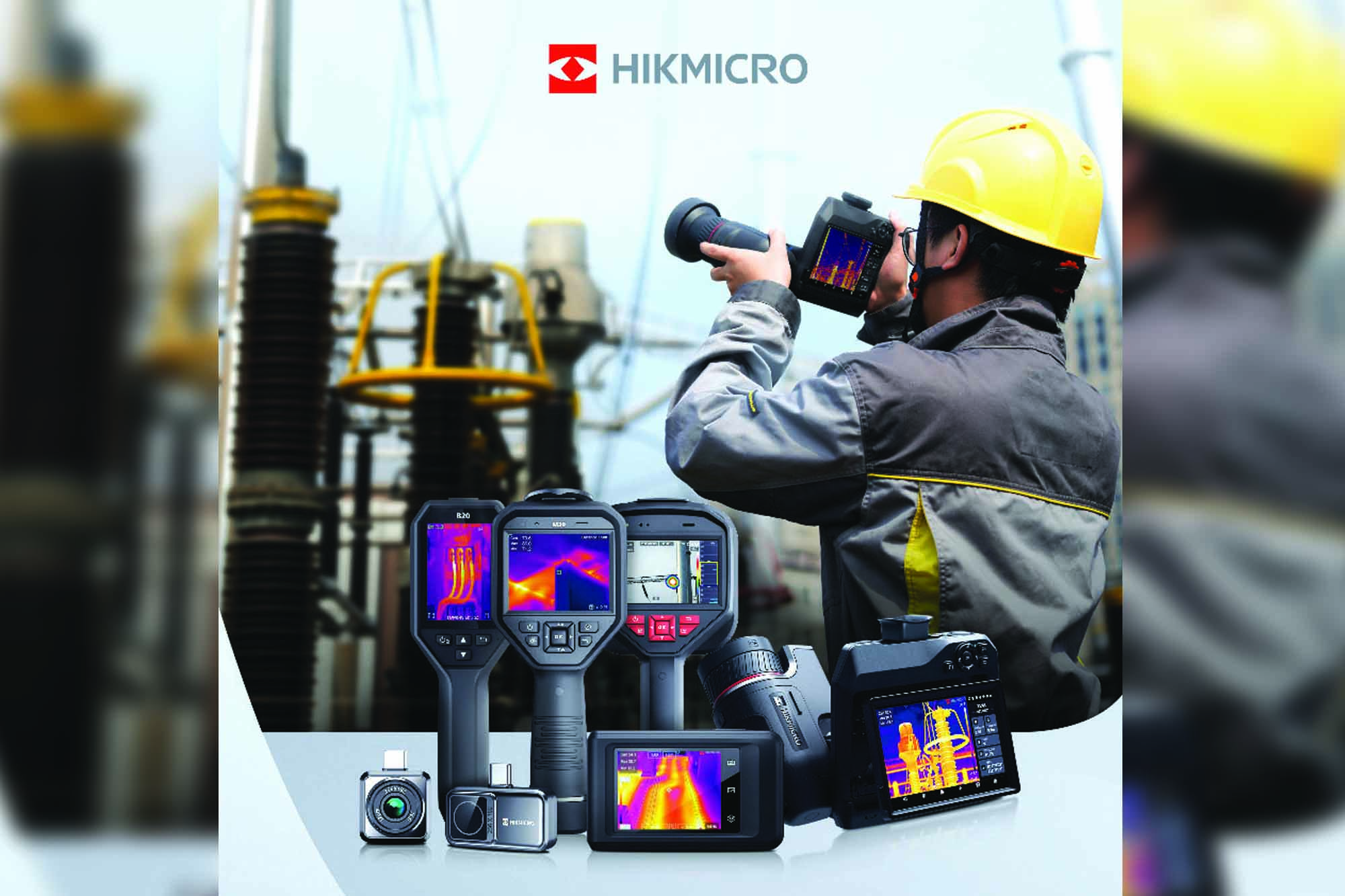

Enhancing the utility’s asset management program is essential. Cutting-edge thermographic inspection cameras play a crucial role in identifying and mitigating equipment issues before they escalate, thereby preventing costly service interruptions. Here’s why you should choose HIKMICRO solutions for conducting periodic thermographic inspections.

The Importance of Proactive Thermographic Inspections:

Cost Savings: Equipment failures and service interruptions are more expensive than preventive maintenance. Our inspections help you avoid downtime and costly repairs.

Invisible Threats: The heat signature of failing components is easily observed with infrared (IR) sensors, even when invisible to the naked eye.

Weather and Load Challenges: Over time, weather changes, load characteristics, and material shifts strain vulnerable points in the electrical system. We have got you covered.

Thermal Imaging Capabilities:

IR Sensors: Not all IR sensors are equal. Our high-resolution IR technology ensures efficiency and accuracy.

Immediate Visualisation: Set temperature thresholds to identify hotspots quickly.

Temperature Gradients: Measure operating temperatures under load.

User-Friendly Interface: Seamlessly switch between camera and IR sensor for efficient inspections.

Our cutting-edge thermal and acoustic cameras, along with software applications, are meticulously tailored for maintenance teams, manufacturing, oil & gas, electrical utility, safety providers, and construction sectors. The top-tier equipment, we offer includes the Thermal Camera SP, G, M, Pocket Mini Series, and Acoustic Camera AI 56. These devices are characterised by superior technical specifications and intuitive interfaces.

Our seasoned support team of industry experts is always ready to assist you. Join us in unleashing the power of our thermal technology for heightened performance and precision in every operation. Connect with HIKMICRO today to delve into a new era of thermal imaging excellence!Hikmicro thermal imaging cameras play a crucial role in preventive maintenance programs for electric power utilities.

Contributions to Maintaining Equipment Reliability and Reducing Costs:

Thermal imaging cameras allow technicians to monitor the temperature of critical equipment regularly. By detecting excess heat, they can identify potential failures before they occur.

A properly working preventive maintenance program can lead to significant savings. Studies estimate that such programs can result in:

By using thermal imaging cameras, facilities can transition from reactive maintenance (emergency repairs) to scheduled inspections, extending the lifespan of machine assets.

Thermal imaging cameras can identify:

Loose connections: Increased resistance generates heat, which can lead to component failure.

Corroded elements: Corrosion affects electrical connections and causes temperature variations.

Short circuits: Detecting abnormal heat patterns helps prevent dangerous faults.

Facilities can integrate thermal imaging with other maintenance tools (vibration analysis, motor circuit analysis, ultrasound, etc.).

Hikmicro thermal imaging cameras are cost-effective tools that enhance safety, prevent equipment failures, and improve overall reliability in electric power utilities.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.