Preventive maintenance of polluted power transformer bushings, insulators

By EPR Magazine Editorial May 6, 2022 2:45 pm IST

By EPR Magazine Editorial May 6, 2022 2:45 pm IST

This article aims to bring your attention to the importance of polluted power transformer bushings/insulators preventive maintenance.

Everyone involved in power utilities experience leakage current losses and power outages on their transmission and distribution infrastructures caused by polluted bushings and insulators.

Outdoor Power Transformer bushings and insulators are subject to surface dirt deposits to some degree in all operational areas. Most commonly encountered contaminants have little effect on insulator performance if the surface is dry.

The pollutants gradually build up on the insulators but do not decrease the insulation strength when the insulators are dry. The user resolves these issues with cold washing and cleaning maintenance work, requiring a few days of power outages, typically one bay or circuit at a time.

Power transformers installed in coastal and inland T&D power grids with climatic areas subject to dry weather followed by fog, mist, and light rain, and in the proximity of contaminants sources, e.g., coal, cement factories, industrial/agricultural, dust, and cooling tower effluent pollutants, the surface of polluted insulators becomes wet.

A conductive layer forms, initiating a current leakage that ultimately causes a flashover; in most cases, several arcing periods may precede an actual flashover.

Without cleaning the pollutants from the insulator surface, fog, mist, or light rain usually create conditions that produce a conducting film on the dirty insulator surface.

To solve or contain such pollution side effects, some users start installing composite and polymer insulators; the equipment (Composite and Polymer bushings/ insulators) is sold emphasising hydrophobicity as the main feature and claiming that the hydrophobic feature is a crucial factor in limiting and preventing leakage currents.

Moreover, preventive maintenance is often emphasised as being minimal and ultimately unnecessary.

Because contaminants settle in dry periods, the pollutant layer covers the hydrophobicity feature; therefore, the paramount quality of being hydrophobic is voided.

With the marketing and sales strategy of the composite and polymeric insulators, all loudly grant that they are maintenance free. With all due respect to the claim that composite and polymer insulators require minimal and ultimately unnecessary maintenance, sooner or later, they must be cleaned. (In the aforementioned climatic zones.)The same is true for RTV-coated bushings and insulators.

The RTV silicone coatings are being sold, emphasising hydrophobicity as the main feature, and claiming that the hydrophobic feature is crucial in limiting leakage currents. This coating is designed to replace silicone grease and water washing and, it is claimed, to eliminate the maintenance cost.

Within a variable length period (time depends on the climatic conditions), RTV coatings degrade, and quite often, the RTV coating peels off, forcing a power outage to resolve issues.

The aim and the challenge of a maintenance programme are to clean insulators without a power outage.

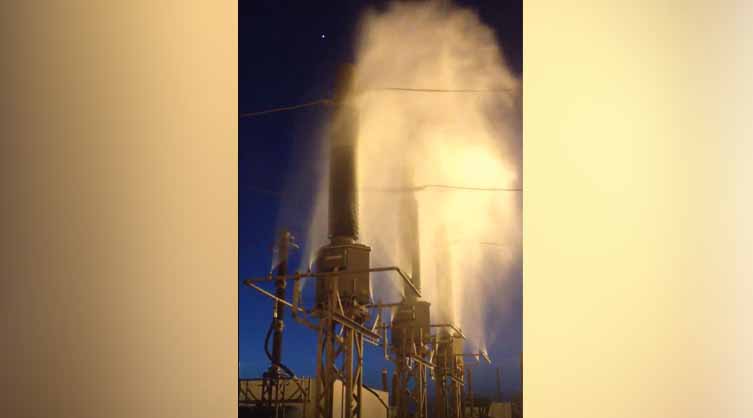

A preventive maintenance program based on an “Energised Washing System” reduces network outages, eliminates repair time and maintenance costs, grants zero flashovers (caused by polluted insulators), attains operational excellence, reduces downtime risk, ensures personnel safety, and achieves financial efficiency by optimising the maintenance budget.

Clean insulators without a power outage. Pros: Reduce:

Clean insulators without a power outage. Pros: Reduce:

Increases:

Optimises:

NOTE: The preventive maintenance plans are chronically suffering from a shortage of funds with limited budget allocation and are often mistakenly squeezed to the minimum.

A customised preventive maintenance program should be adopted and seasonally adjusted.

The washing frequency, seasonally programmable, is dictated by the type of contaminant and its build-up rate on the bushings and insulators.

For more details, please visit; https://www.wilorton.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.