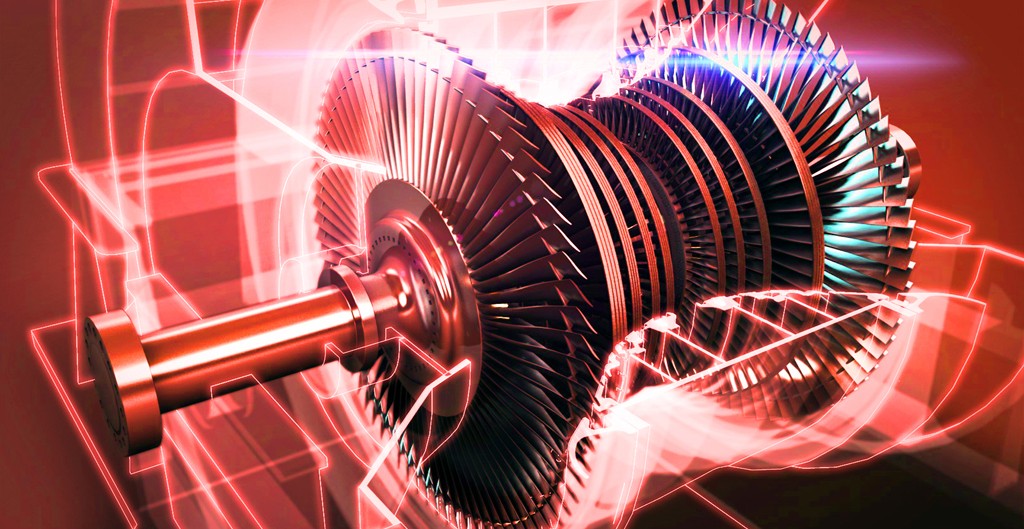

Boosting the power sector with turbines

By EPR Magazine Editorial April 3, 2017 2:39 am IST

By EPR Magazine Editorial April 3, 2017 2:39 am IST

Discussion on turbine industry’s status, growth drivers and offerings

With a total thermal installed capacity of 212 GW (as of May, 2016), India is the world’s fifth largest producer and consumer of electricity. With proven coal reserves of 126 billion tonne (as on 01/04/2014) and natural gas reserve of 1,489 billion cu.m (as on 01/04/2015), thermal power generation remains the most preferred method.

While sharing his views on the status of turbine industry Arun Mote, Executive Director, Triveni Turbine Ltd said, “The global steam turbine market was around 21 GW in 2015 and is projected to increase to 26 GW by 2020. The Indian steam turbine market was around 2.5 GW in 2015 and is projected to reach 3 GW by 2020.”

The turbine industry is doing well and the industry is opting more for efficient products believes Aditya Gandhi, Partner, Nitin Corporation. He says, “The turbine industry is doing well and the primary technology behind turbine application has been very constant for the last 60 years. Today, the industry is opting for more and more efficient machines which operate at higher steam pressures and temperatures. Also the technology trends in the turbine industry have remained constant and the demand depends upon the industrial activity. So, as such, there is no change and substitution of product for turbines.”

Major growth drivers for turbines

Turbines are also playing a major role in boosting the power sector but it is important to know what the major growth drivers for the same are. Mote shares major growth drivers for thermal turbines in India are:

Major growth drivers for the turbine industry are clarity of policy regarding availability of coal and other raw materials, believes Gandhi. He adds, “To drive the sector, it is essential that the industrial activity increases so the demand for power grows as well as more power plants are installed. Also, clarity in the regulations regarding cogeneration and installation of more cogeneration plants is leading to an increase in the number of installation in this sector. Also, substitution of the low pressure and low temperature and inefficient machines by larger efficient ones is also important for the growth.”

Offerings and expertise

Triveni Turbine manufactures and supplies engineered-to-order steam turbines up to 30 MW. With our steam turbines running in over 70 countries and across 18 different industries, we have an installed base of above 12,000 MWe. Triveni also provides after-sales services such as erection and commissioning, periodic overhauling, long term service agreements, spares, comprehensive O&M services and refurbishing. It has the capacity to manufacture over 150 turbines annually. “We deliver steam turbines in the above 30 to 100 MW range through our subsidiary – GE Triveni Limited, a Joint venture with General Electric,” says Mote.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.