Rewinding critical electrical equipment parameters

By Admin October 15, 2019 3:18 pm IST

By Admin October 15, 2019 3:18 pm IST

Growth in the power industry is expected to drive growth in the electrical equipment industry. However, there are issues that need to be addresses before we attain a global status quo. Here, we discuss three verticals of electrical equipment, meters, transformers and explosion proof equipment, the critical aspects of Indian electrical sector and the issues they face and solutions. for the same

An efficient power supply system is a key requirement for a nation‘s economic growth and the quality life of its citizens. Assured availability of quality power at a reasonable cost will not only act as a catalyst in the socio-economic development of the country, but also enhance the global competitiveness of the electric equipment sector.

Meters

As India makes rapid strides towards its vision of providing universal access to affordable power, it becomes important to eliminate the challenges faced by DISCOMs. To overcome challenges such as billing inefficiencies, unauthorised power consumption, and DISCOMs’ financial woes, the Government of India is accelerating the adoption of smart meters.

Venkatesh Dwivedi, Director (Projects), Energy Efficiency Services Limited is pleased to support the DISCOMs in their pursuit of energy sustainability and accountability with the adoption of future-ready technologies like Smart Meters. He says, “Thrust on such efficient systems is critical for sustainable consumption, growth and enhances consumer experience through improved service delivery.”

Smart meters are an integral part of the overall Advanced Metering Infrastructure solution (AMI) that measures and records consumers’ electricity usage at different times of the day and sends this information to the energy supplier through GPRS technology. This gives consumers better access to information and enables them to make more informed decisions on the use of electricity in their homes. This can immediately control the AT&C losses resulting from power pilferage, bypassing meters, defective meters, or errors in meter reading. Dwivedi says, “Every kilowatt of power drawn from the grid is thus accounted for – and billed, thereby reviving DISCOM revenues.”

Through these smart meters, consumers have access to prepaid billing model, which is quite remarkable, as it enables the consumers to pay in accordance with their ability, convenience and usage. Smart meters with Advanced Metering Infrastructure solution (AMI), will help monitor and records consumers’ electricity usage at different times of the day and sends the information to energy supplier through GPRS technology. These meters also eliminate the task of monthly manual meter reading, whose billing inaccuracies and delays are borne as costs to the DISCOMs. Therefore, Dwivedi says,“ Under-billing or inadequate billing can become a thing of the past, further contributing to revenues. By using remote disconnection, DISCOMs can instantly stem power theft. Consumers get better access to information and enable them to make more informed decisions on the use of electricity in their homes and thus avail monetary savings.”

Underlining EESL’s mission of ‘Enabling more – more efficiency and more innovation”, Dwivedi believes that efficient and future-ready transformative solutions must create a win-win situation for every stakeholder. This will ensure that the rollout of our various programmes is truly effective. He says, “We are achieving this inclusively advantageous proposition by incentivising all the stakeholders in the value chain. With respect to the Smart Meter National Programme (SMNP), EESL has ensured the proper readiness of the ecosystem, the capacity building of DISCOMs and objective specific AMI solution to DISCOMs.”

EESL is enabling DISCOMs to benefit from zero upfront financial investment through our unique model – Pay-as-you-save (PAYS). This model has been at the core of the successful implementation and the positive experience of partner DISCOMs. EESL procures smart meters, as well as services of the system integrator with 100 percent investment, enabling DISCOMs to benefit with this investment. Their repayment to EESL is through the monetisation of energy savings, resulting from enhanced billing accuracy, avoided meter reading costs and other efficiencies. These savings further enable DISCOMs to invest in value-added services for its consumers.

As the backbone of India’s power industry, India’s DISCOM sector must participate in this new era of energy accountability that will enable citizens’ access to sustainable and reliable energy. The smart meter technology is critical to India’s ongoing power sector reforms.

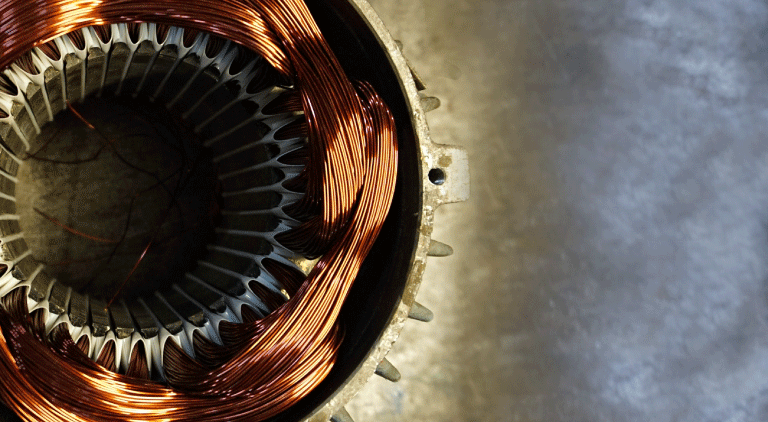

Transformers

UDAY was launched by the Government of India to encourage operational and financial turnaround of DISCOMS, with an aim to reduce the AT&C losses to 15 per cent by FY19. The rate of failure of distribution transformers in India is higher as compared to developed countries. This high failure rate is cause of concern to all the DISCOMs in the country.

Risks and failures

Transformer system, especially distribution transformers, in itself is a very complex system and it requires continuous monitoring and maintenance. However in spite of that there are transformer failures generally are seen in India (95 per cent of them in rural areas).

Saurabh Pataria , CEO, National Electrical Equipments Corporation highlights the following reasons:

Explosion proof equipment

The explosion proof electrical equipment industry keeps on upgrading itself with new innovations at the same time keeping the basic principles of explosion proof design and principle of explosion proof design and safety intact. Likewise, the design and standards of explosion proof electrical equipment is constantly upgraded periodically to attain safer equipment for use in hazardous locations. Surojit Ray, Partner, Flameproof Consulting Agency says, “The testing laboratories have continuously upgraded their testing facilities to provide certifications for new and innovative products. The last standard being used for Explosion proof electrical equipment viz: IS/IEC60079-1:2007 is being upgraded again with changes to make the hazardous locations a safer place to work.”

Opportunities

As our standards are being constantly upgraded and gets more aligned to newer standards, which is being introduced/practiced in other parts of the developed world (although, we have the same standard as IEC60079-1 as the EU and corresponding American NEC standard – but with our own changes in them to suit our conditions), the acceptability of our equipment grows beyond our geographical boundaries. Ray says, “With high levels of production and engineering capabilities of Indian manufacturers and availability in abundance of skilled, semi-skilled and unskilled labour in India at a low cost in comparison to developed countries – the opportunities seem endless as of now.”

The advent of international (mainly European) laboratories opening their facilities in India to provide EU certificates have opened new markets world-wide for the Indian manufacturers. Also, the upgradation of Indian Oil & Gas refineries and installations has generated a lot of business in the industry and this is going to continue for another few years to come.

Risks

According to Ray, the Indian manufactured explosion proof electrical equipment does not have much to worry about as of today. However, internationally, the embargo nations having sanctions put on them (especially oil rich nations) find it very difficult or even impossible to trade with Indian manufacturers, posing a serious hindrance for the industry.

Also, some developed countries that try and sell their own countries’ manufactured explosion proof electrical equipment, who are also consultants to other countries, prohibit the use and buy of Indian manufactured (Made in India) explosion proof electrical equipment without any substantial reasoning. This is inspite of these Indian equipment having the same international certificates issued from the same testing laboratories as the ones being sold by the developed countries.

The Indian companies have to face competition from their peers in the Indian market regularly However, as the industry is small – everybody has enough on their plates. Ray says, “The industry in India is thriving for manufacturers who have suitable quality control and up-to-date prevailing certifications and have themselves enlisted with all major oil & gas refiners/installations (government/private/public-private owned) in India.

The international market is open to players who have the requisite international certificates like ATEX/IECEx (EU) and can easily bag a good portion of the demands due to low cost of products with the same high qualities the international clients expect out of these products. The going seems to be great so far for the Indian explosion proof equipment industry, says Ray.

Failure occurs due to degradation of the insulation material due to overloading of the transformers.

Saurabh Pataria , CEO, National Electrical Equipments Corporation

The design and standards of explosion proof electrical equipment is constantly upgraded periodically to attain safer equipment for use in hazardous locations.

Surojit Ray, Partner, Flameproof Consulting Agency

Every kilowatt of power drawn from the grid is thus accounted for – and billed, thereby reviving DISCOM revenues.

Venkatesh Dwivedi, Director (Projects), Energy Efficiency Services Limited

The rate of failure of distribution transformers are too high, as the power utilities are not maintained as per the recommendations prescribed by the manufacturers

Parag Yelegaonkar, Business Development Manager, Government Business, Testo India Pvt. Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.