Solar cable management and its essentialities

By EPR Magazine Editorial October 16, 2019 5:24 pm IST

By EPR Magazine Editorial October 16, 2019 5:24 pm IST

One of the most important tasks when installing a PV system is cable management. Here, the industry experts discuss the importance of having proper management system in place for the same and its market challenges.

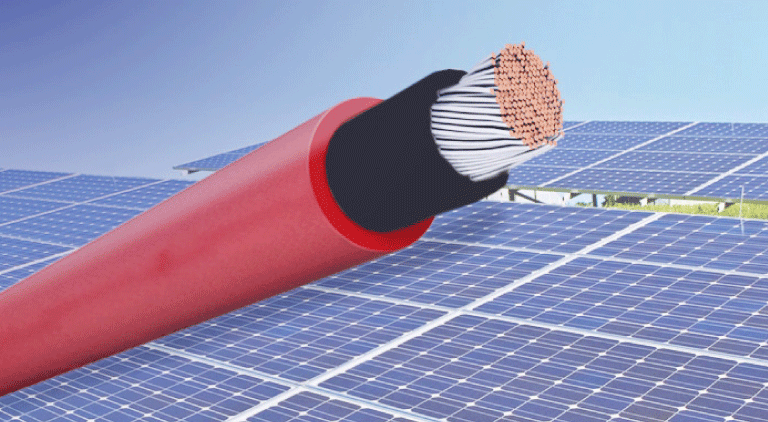

Amidst, the growth of solar cables, its management is an important step in panel or PV installation. Commonly installed on rooftops for homes and businesses and on solar farms, PV systems depend on a complex array of wires and cables to harvest renewable energy. These components are subject to extreme temperatures and often direct sunlight, wind, snow and rain. With proper wire management, solar panels can last more than 25 years. Careless cable management after PV installation will lead to losses. Cables are subjected to thermal, mechanical, and external loads. Just like the rest of the system, cables need to last the stipulated 25 years or more. Damage not only jeopardises the system’s reliability, but also its safety.

Cable management for project reliability, safety and life

Wire management is important because it minimizes maintenance, optimizes safety and thus enhances life of wire and system. Cables are one of the most critical aspect of solar plants and therefore requires a stringent management process. Wire management becomes necessary to avoid on site failures, which could result in high financial setbacks. Standard parameters for wire management like cable routing, cable bending, cable insulation etc., will help maintain uniformity throughout the manufacturing process, and standard quality cable will be delivered to solar PV plants.

Cables are designed to operate for a period of 20-25 years in solar power plants. The cables undergo high temperature, moisture, reptiles etc., which could harm cable and affect performance of cables and therefore the output of the plant. Neelaksh Pathak, Business Development-Manager, HPL Electric & Power Ltd. says, “Cable manufactures take in to consideration the stress and challenges that the cable undergoes during the product life cycle and develop cable products, maintaining highest quality standards. For cable manufactures, reliability and life span are the prime focus area. I would like to draw attention of all end users to choose product wisely so as to avoid hazardous situation and for achieving longer plant life to ensure high return on investment.”

Proper wire management minimises maintenance, optimises safety and enables longer-lasting systems. Wire is essential part of any solar plant; there are three major importance of wire in solar project according to Nitesh Vaghasiya, Chairman & Managing Director, Ultracab (India) Ltd.:

Cable management solutions

As per application and weather conditions Vaghasiya suggests the following three different style of solar cables:

All above three cables have different range of temperature rating and properties. Customer may choose as per their project requirements.

Market challenges

It is important to deal with balance of system and manufacture entire range of solar solutions for the end consumers, while maintaining tough quality checks to increase reliability and performance of the products is important. Pathak says, “We undergo several quality checks in our manufacturing process to achieve zero onsite failure for our cables. In terms of wire management, we consider quality of compounds as top priority, and follow a scientific manufacturing processes to deliver a product, which can face tough climatically challenges. We ensure the same by undertake in-house testing of manufactured lots to meet technical requirements. We make certain that wire shouldn’t be clipped tight with cable tie, maintaining bending radius of cable, proper cable routing, proper crimping, insulation should be accurate, these are some keys solution that we offer in our manufacturing process to meet world class standards.”

Vaghasiya, too, is of the same opinion. He says, “With the rise in major challenges for non-standard products, not well in quality, cheaper, and easily available in market, the customers are confused to choose right products with best quality.” Further, the cost of the solar wires is high due to high tax levied on it. The government should reduce the GST rate on solar wires and cables would make it affordable to customers and encourage them to use renewable and eco-friendly energy.

Manufactures take in to consideration the stress and challenges the cable undergoes during its life cycle and develop cable products, maintaining highest quality standards.

Neelaksh Pathak, Business Development-Manager, HPL Electric & Power Ltd.

GST reduction on solar cables will make it affordable to customers and encourage them to use renewable and eco-friendly energy

Nitesh Vaghasiya, Chairman & Managing Director, Ultracab (India) Ltd.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.