Green, clean, smart: When solar power plant meets digitalisation

By EPR Magazine Editorial May 10, 2019 11:33 am IST

By EPR Magazine Editorial May 10, 2019 11:33 am IST

Large solar power plants are spread out geographically and are typically distributed over large areas and in remote locations. This, in essence, coupled with the need for efficiency and the large volumes of real-time data, drives the need for the implementation of digital technologies in this industry. Declining tariff rates and a simultaneous rise in O&M costs push solar company CXOs to think of new ways to maintain their competitive edge. The industry has, thus, steadily been embracing smart technologies and exploiting their benefits to gain faster ROI.

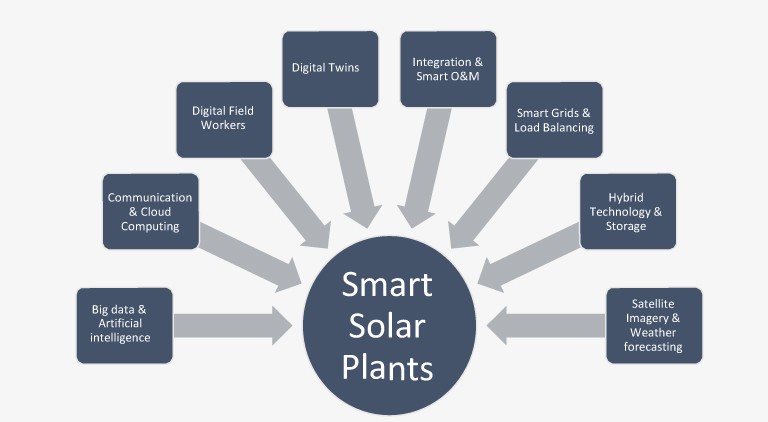

While it is still debatable as to what comprises smart technologies with respect to solar, given below are some of the key technologies that help in the smart operations of a solar power plant.

Big Data & Artificial Intelligence

A typical utility scale solar power plant has several hundred components working concurrently. The data generated from these systems can reach several GBs per second. It, therefore, becomes a challenge to analyse the data and identify specific problems in a power plant, unless there is a tool or a performance improvement key to analyse data in real-time, providing alerts during non- performance. It is essential to use reliable software that can provide consistent results, low false positive and reliable data security.

Artificial Intelligence should also provide actionable recommendations (e.g., cleaning recommendation) that can help in choosing next steps without spending much time in data analysis. The recommendations should be configured to cover the entire power plant, right from the module level, up to the main feeder or energy meter level. AI should also be able to tell the health of the asset, the risk of failures, and asset degradation steps to reduce rate of degradation.

Communication & connectivity

While we talk about Big data, it is also vital to have such enormous amounts of data transferred from remote power plants to a central location without any data loss/theft. One of the key issues here is availability of reliable internet connectivity in such remote locations. It is required to have redundancy in connectivity of leased lines, and continuous monitoring for early assessment and resolution of any connectivity related issues that may arise. In cases where frequent connectivity issues are anticipated, a data collector (a desktop computer) can be placed in the remote site to pool the data from the parks, store the data and send it to the central location when internet connectivity is available again.

With widespread prevalence of mobile internet usage amongst business users, O&M heads can opt to check plant performance in real-time and give instruction to the site team whenever and from wherever.

Cloud computing

It is an unstated requisite for power generation companies to focus on the core of their business. Data storage, in essence, is a non-core activity for a solar power generator, and it becomes cumbersome to manage server infrastructure. Cloud based storage helps in this, and off-late, data security protocols have been upgraded to higher standards. Nevertheless, there is still apprehension in using the cloud for data storage and for data heavy organisations, such as in the power industry, a server based infrastructure or a hybrid model is ideal.

Digital field workers

Usage of drones and robots in inspection and cleaning has become common with most solar companies; usage of such systems could help in resource optimisation and cost benefits. Thermal imaging done using drones can be sent in through image recognition algorithms to identify the severity and type of degradation, at module level. This will help identify some common problems and arrest any loss at symptomatic stages itself. The inspections are faster, large scale, timely and cost effective, with the need for a site visit eliminated.

In desert environments, the dry, arid climate and the abrasiveness of the sand makes the panel degrade fast. Over-cleaning or under-cleaning a solar plant results in high O&M costs or reduced yield respectively. Water consumption to clean solar panels at remote locations can be greatly reduced through robotic cleaning.

Digital twins

A digital twin is a physical replica of a real asset that is present on the field. Whether it is a solar park or a wind farm or any other asset, digital twins display real-time conditions of the actual system in the remote location. From the smallest component of the asset, up to terrain variations, digital twins can provide data to any level of sophistication. Digital twins can also be customised to display color codes according to asset performance or asset risk ranks. Digital twins can also be used to control total plant operations from a central monitoring station.

In a power plant, there are several hundreds of systems/components that have different protocols of communication. It is required that some sort of a middleware that can communicate with all the devices/components integrate them in a common platform for further processes. Solar plants last for about 20 – 25 years. Hence, new technology that is adopted should have the capability to accommodate legacy systems with minimum upgrades or retrofits. Contemporary equipment can accommodate third party interfaces and allow for third-party data sharing.

It is important for O&M teams to focus on key issues, rather than focusing on non-value activities such as report creation or co-ordination. Therefore, integration systems should also be able to pull in data from Enterprise Resource planning (ERP), Enterprise asset management (EAM), IOT devices, FTP files, Historians, databases and many other manual records. Easy-to-use integration software can be used here to make O&M teams highly productive.

Analytics softwares are available in the market, which help by providing real-time intelligence to O&M teams, through which we can understand which assets to focus on and plot a course of action.

Such systems help identify assets to curtail in cases of excess power production, considering asset efficiency, health, remaining asset life, etc. Analytics engines can also identify assets that could potentially fail in the near future and recommend actions to make the whole O&M process smart and efficient. Some of the components such as tracker motors can also be maintained proactively so as to ensure that they don’t fail and spur a loss in production.

Smart grids and load balancing

Smart grids are electrical grids that can communicate and process data digitally, helping in optimised use of energy resources and power supply. Applications include (but not limited to) storage, accommodation of hybrid technology, smart meters, sensors across T&D lines, forecasting and load balancing, cyber security, information sharing, faster restoration of grids after disturbance, and accommodation of intermittent renewable energy sources.

For grid security, proper forecasting of energy generation, electricity demand and reliable weather data are important. In countries like India, the load dispatch centers have, thus, mandated power generators to forecast energy generation for a forward period of 24 hours in 15 min slots. The use of digital technology in load balancing can avoid large scale grid black outs and thus preserve the interests of both energy producers and consumers.

Hybrid technology and storage

Solar power not being available for the entire day can be stored or complemented with thermal or wind power in order to be used as a base load. This also helps in efficient utilisation of grid and avoidance of grid imbalances. In the meanwhile, extensive research is being done for storage of power for large scale solar power plants. Many solar organisations are conducting pilots with various storage technologies to understand what could work. A proper cost benefit analysis, evaluation of technical & commercial risks and usage of technology can make hybrid technology and such energy storage viable in the future.

Satellite imaging and weather forecasting

Availability of weather data through satellites helps tremendously as it covers a larger geography than a local weather station on field. The atmospheric data collected can be processed through image processing or data processing algorithms to get clarity on the cloud coverage, cloud movement, and expected weather over a period of time. Long term availability of reliable weather data can ensure proper budgeting and expectations of energy generation at a particular solar plant.

Authored article by:

Lakshman Rao Ramesh Sutrave

lakshman.sutrave@bahwancybertek.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.