Being predictive and preventive with electrical equipment

By EPR Magazine Editorial March 8, 2019 1:48 pm IST

By EPR Magazine Editorial March 8, 2019 1:48 pm IST

An industry analysis on what predictive and preventive maintenance tools can do for an effective programming of electrical instruments

All electrical equipment whether used for generation, transmission or distribution of electricity need periodic maintenance. By regularly checking the health of the equipment, major shutdowns can be avoided.

Predictive vs preventative maintenance

We are witnessing a new revolution in trends and technology of operations in all the industries, especially, T&M sector, which has multiple roles to play in predictive and preventive maintenance. Although both are equally important, the former tries to predict the failure or breakdown even before it happens while the latter enables you to implement strategic maintenance which is periodic and pre-planned.

Parag Yelegaonkar, Manager – Business Development, Testo India Pvt Ltd, says, “Practically, predictive maintenance is being preferred as it tries to determine the actual condition of the equipment or component instead of an early or delayed predefined inspection. It also helps to conduct the maintenance job without shutting down the system, keeping the operational losses to minimum.”

Today, we are living in 4th version of industry, which means growing to have competency of next-gen technology and stability in a competitive atmosphere including awareness in less optimisation of OPEX/CAPEX. Suneel Kapoor, Country Lead, Kyoritsu KEW India Instruments Pvt Ltd states, “As being part of testing and measuring segment, we always emphasis on customer’s requirement v/s service delivery, though we always try to provide best solution in terms of latest technology based of reliability and consistency.” The difference between preventive and predictive maintenance is that preventive maintenance tasks are completed when the machines are shut down and predictive maintenance activities are carried out as the machines are running in their normal production modes.

There are many test and measuring instruments, which can predict the trend of ageing and safety of the equipment and by observing the values at regular intervals, the likely occurrence of failure can be predicted. Chandmal Goliya, Director, Kusam Electrical Industries Limited says, “By observing the Polarisation Index of the insulation of cables, motor transformers etc. We can get to know the rate of deterioration of the insulation. With this information, we can take timely and necessary measures to prevent the failure of the equipment. Also, by the use of battery quality analyser, the rate of deterioration of the system batteries can be known in advance so as to avoid breakdown of the UPS backup system.”

Preventive maintenance is carried out at regular intervals to ensure that the equipment functions properly by providing for systematic inspection, detection, and correction of incipient failures, either before they occur or before they develop into major defects. It is a regular and routine action taken on equipment in order to prevent its breakdown. It includes tests measurements, adjustments, parts replacement, and cleaning and servicing performed specifically to prevent faults from occurring.

The maintenance tools

Predictive maintenance is a philosophy that uses the equipment’s operating condition to make data-driven decisions and improve quality, productivity and profitability. In test and measuring space, Kyoritsu provides their customer with the best product solution for specific product line. According to present scenario, predictive maintenance is not a tool, technique or certification. Most predictive maintenance is performed while equipment is operating normally so as to minimise disruptions to everyday operations.

Kapoor asserts, “For predictive maintenance to be effective, it requires both hardware to monitor the equipment and software to generate the corrective work order when a potential problem is detected.Based on frequent customer requirements Kyoritsu deliver shardware monitoring with Ethernet/Bluetooth facility for online monitoring in case of troubleshooting and daily operation.”

Most predictive maintenance is carried out while the equipment is in service, the technology to be used should be non-destructive such as infrared, acoustic, partial discharge, ultrasonic, corona detection, vibration analysis, sound level, measurements, oil analysis etc., says Goliya. Various industries such as railways, manufacturing, automobile, oil & gas, etc. use one or more of the above methods for predictive maintenance.

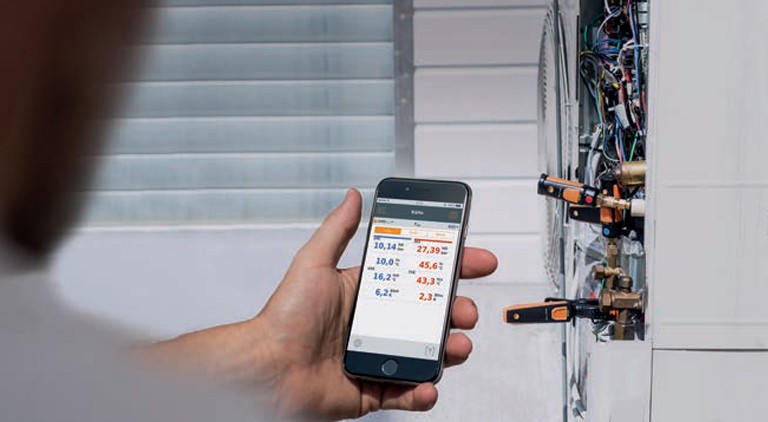

“Considering our latest and most advanced solutions for instance, our electrical instruments are very distinct and unique in their features. They are excellent instruments to inspect the electrical components and circuit failure threats. Along with that they ensure longevity and efficiency of various power electronic components that control and regulate the flow of electrical energy,” says Yelegaonkar.

Smart probes and thermal imagersTesto’s latest solution to the industry, the new range of Thermal Imagers with smartphone integration is designed to deliver networked thermography mostly used for predictive and preventive maintenance in electric and power sector. Wireless operation, with the ease of saving and transferring data over networks makes an instrument more users friendly, interactive and cost effective.

Being fundamental to Industry 4.0

Industry 4.0, in itself, is invariably a continuous setup of smart operational framework and consists of relatively expensive assets and equipment. With an increasing inclination on IoT, machine learning and smart technology, there is a complete transition of processes and thus predictive maintenance becomes very critical in this new phase.

During the installation phase, the necessary predictive T&M equipment are very much required and is used in setting up benchmark parameters for various process tags. This recorded benchmarked parameter can be used to check and confirm the safe and efficient operation of the industry throughout its life cycle span. Be it manufacturing, automotive, power sector or any other industry, predictive maintenance is crucial in optimising operation and for all kinds of trouble shooting jobs. Yelegaonkar says, “A small lapse in predictive maintenance can lead to highly unsafe conditions and thus results in loss of huge revenue and system breakdown, which can be easily corrected with equipment like testo Thermal Imagers and electrical instruments.”

Industry 4.0 sectors such as managing SCM, smart factory/system integration, plant safety and security/IoT play a very intensive rolein Indian techno commercial market. Though predictive maintenance is a seamless parameter, which performs a very penetrating role in the growth of industries, also becomes one of the useful vehicle to reduce CAPEX in maintenance’ perspective. Kapoor says, “Kyoritsu always aggressively invent and introduce product which stand for customer’s need in way of innovation.”

Goliya concludes, “As compared to traditional factories, Industry 4.0 factory, in addition to its condition monitoring and fault diagnosis, components and systems are able to gain self-awareness to beself-predictive and provide management with more insight on the status of the factory.”

By observing the Polarisation Index of the insulation of cables, motor transformers, we can get to know the rate of deterioration of the insulation

Chandmal Goliya, Director, Kusam Electrical Industries Limited

A small lapse in predictive maintenance can lead to highly unsafe conditions

Parag Yelegaonkar, Manager – Business Development, Testo India Pvt Ltd

For predictive maintenance to be effective, it requires both hardware to monitor the equipment and software to generate the corrective work order

Suneel Kapoor, Country Lead, Kyoritsu KEW India Instruments Pvt Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.