IoT: T&M’s latest ‘buzz’ word

By EPR Magazine Editorial January 5, 2019 2:44 pm IST

By EPR Magazine Editorial January 5, 2019 2:44 pm IST

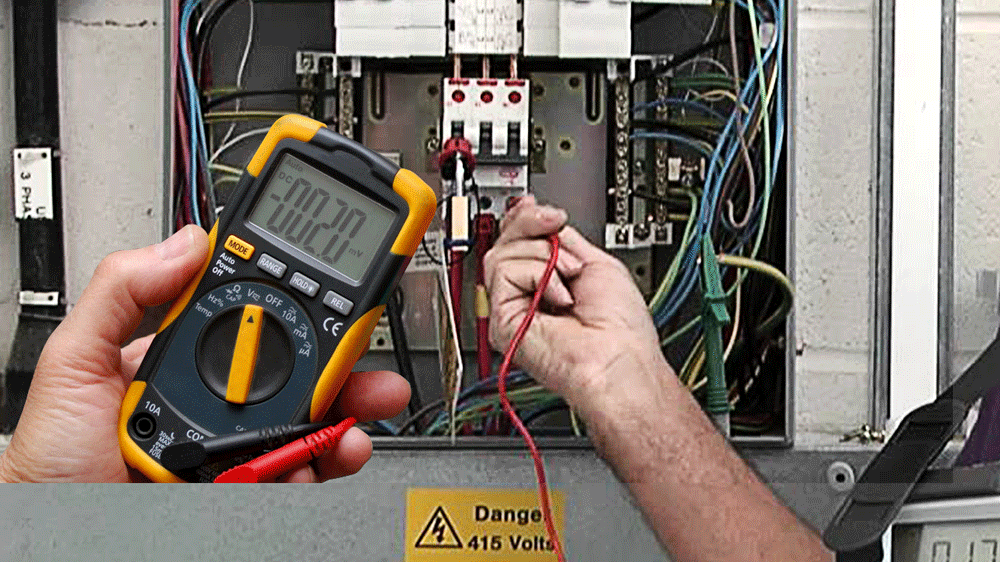

T&M plays a vital role in the power sector. Certifying, calibrating and assessing the reliability and quality of each equipment. Here, the industry experts discuss how to keep abreast with the latest technologies to ensure accuracy.

Energy demand is increasing every year and new technology has helped to save and generate more energy.

The growth prospects of T&M equipment related to the power sector

Test and measurement plays a major role in the R&D of new products’ design and validation and once system is deployed in production and distribution. Demand is being driven by stringent policies, upscaled energy efficiency of devices and instruments apart from the regular standards.

Madhukar Tripathi, Head- Marketing and Optical Business, Anritsu India Pvt Ltd says, “Many test and measurement instruments are required for efficient operation of production and distribution. Government is establishing new power plants and have instrumentation lab where regular maintenance is carried out.”

New power plants are connected to the Head Office and other locations using new optical fiber communication (OFC) technology. OPGW is being implemented in many states/private power pants. Optical fiber helps to transmit data faster to other location and receive report as well along with routine communication needs.

Chandmal Goliya, Director, Kusam Electrical Industries Ltd. says, “Due to an increase in the capacities of the power sector, the requirement for test andmeasuring instruments will grow in generation, distribution and transmission of electricity.” We see a growth of at least 22-25 per cent demand for test and measuring instruments in the coming years.

Technology aspect in T&M

The T&M sector is rapidly changing. With the advent of new AI technologies and increasing demand for electricity, T&M will expand from only offline portable testing, to a combination of offline and online monitoring. Yash Kulkarni, Head- Marketing, Scope T & M Pvt Ltd says, “The data from the test devices will be analysed through powerful machine learning backed AI to predict equipment failures and defer the need for taking DUTs out of service for maintenance.”

The more, the smaller

With the development of technology, many smart devices have been invented for the ease convenience of mankind. These devices can be used both for domestic use as well as for industrial applications. For the smart devices to function correctly under different environments, it is necessary to test them for various environmental and functional compliances.

Goliya of Kusam Electrical Industries Ltd. says, “To carry out the tests, test and measuring instruments play a very important role to check the correct functioning of each of the devices because ultimately it boils down to the measurement of electrical parameters. New test and measuring instruments will have remote transmission of data by bluetooth and wireless means.

Smart devices have created new challenges and roles for testing companies. Electronics is getting smaller and more complicated. Tripathi of Anritsu India says, “All smart devices are connected to one or more devices and connectivity test in important as well as key area of selection and performance. Anritsu Test and Measurement solution has been instrumental in providing connectivity test in smart devices such as Bluetooth test or WiFi test.”

Smart devices and AI provides insights into the equipment’s health which otherwise remain unknown to the maintenance team. Kulkarni of Scope T&M PVT. LTD. says,” Results and data are compared with similar clusters of equipment, identifying whether major maintenance services are required or can be deferred for later. Health scores of DUTs is calculated and the risk of maintenance enables better decision making.”

IoT device testing

T&M’s wireless communication technologiesTRIPATHI says, “Anritsu Wireless Test Set MT8870A is very useful and powerful testing tool for IoT devices.” Wireless communications technologies used by IoT include LTE, NB-IoT, Cat-M, Wireless LAN (Wi-Fi, WLAN), Bluetooth®, etc. Customers developing and manufacturing IoT devices must be able to choose the best wireless communications standard matching the features of their product under development. Key elements in selecting the wireless communications standard are the range, speed, and power consumption. For example, since a battery-powered IoT device must operate for long periods of time, power consumption is most important in this case.

Each communication’s standard has specific characteristics; bluetooth, for example, features low speeds, short range, and low power consumption, making it ideal for use in cordless headphones and healthcare devices, such as sphygmomanometers and pulse rate monitors.

Wireless LAN (Wi-Fi, WLAN) features faster speed than bluetooth as well as longer range and higher power consumption, making it ideal for smartphones, tablets and smart home equipment, such as air conditioners and refrigerators.

Moreover, standards limited to IoT applications, such as NB-IoT, Cat-M, etc., use the same base stations as LTE for communications. As a result, they have many outside use cases, such as smart car rentals, smart agricultural equipment, smart ranching (animal tagging), etc.

Lastly, the recent focus on 5G as a wireless service featuring large data capacity, ultra-fast speeds, and low latency, is driving verification testing in many different fields, including self-driving vehicles in partnership with mobile operators, equipment vendors, and service providers, as well as 4K/8K HDTV, remote building monitoring, and more.

Government is establishing new power plants and have instrumentation lab where regular maintenance is carried out.

Madhukar Tripathi, Head- Marketing and Optical Business, Anritsu India Pvt Ltd

New test and measuring instruments will have remote transmission of data by bluetooth and wireless means.

Chandmal Goliya, Director, Kusam Electrical Industries Ltd.

Health scores of DUTs is calculated and the risk of maintenance enables better decision making.

Yash Kulkarni, Head- Marketing, Scope T & M Pvt Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.