Measuring power quality in electrical installations

By EPR Magazine Editorial August 5, 2020 4:18 pm IST

By EPR Magazine Editorial August 5, 2020 4:18 pm IST

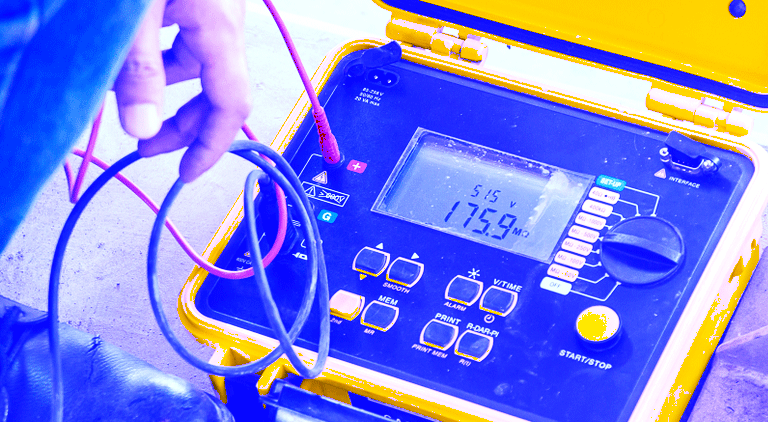

The report highlights the role of T&M instruments in measuring power quality in electrical installations

Power quality is gaining importance in every segment due to the increased usage of inverter based technology, sensitivity of modern equipment and components, demand supply gap and its impact on economy, process and product quality, etc. Countries focusing on clean alternative energy generation through inverter-based technologies like solar and wind, too is contributing to its share of power quality related reliability issues. Today the engineers and business owners are increasingly aware of the importance of good power quality and are willing to adapt to newer technologies and ensure better quality of their production, process and economy.

Talking about the role of test and measurement (T&M) instruments in measuring power quality in electrical installations, Prabhakaran PV, Head – Product Management, Fluke India said, “T&M instruments play a very important role in identifying power quality issues correctly from the grid to end-user levels. Most of the power quality issues are not known to the users and occurs when least expected. If you can measure such unknown events and quantities accurately and reliably, you will be able to manage it better or take necessary action before it is too late. Good quality, reliable T&M instruments help one to take an informed decision on corrective actions to be taken.”

Further, due to the increase in non-linear loads in the industries, it has now become evident to measure the quality of power at the industry premises so as to mitigate the ill effects of the electrical pollutants emitted by these loads in an electrical system. The first step to mitigate power quality issues is to measure and monitor the electrical parameters. And there comes the role of test and measurement equipment that can measure all the required parameter with high accuracy. Narendra Goliya, CMD, Rishabh Instruments Pvt Ltd said, “Measuring tools used for the measurement of parameters like voltage swell, sag, interruptions, and harmonics are required to be designed with a precise and powerful hardware tool that can sustain and work efficiently in critical electrical environments. Such powerful tools help analyse the system parameters over a larger span of time and provided an integrated report at the end specifying the health of the system. These devices become essential when power quality audits are to be taken for preventive maintenance as well as for fault analysis post breakdown. Implementation of a good power quality measuring tool or device helps indicate the health of the system proactively to avoid future damage on the system.”

According to R Mallikarjuna, General Manager – Power quality test and measurement solutions, Atandra Energy Pvt Ltd, “Measuring power quality parameters, assessing their impact on sensitive equipment and adopting meaningful preventive measures is imperative for industry to ensure minimum downtimes. Towards this objective, choosing the T&M instruments of right quality, specifications and accuracy is the key to achieve the objectives.” KRYKARD from Atandra Energy offers a range of power quality measurement and mitigation solutions and related T&M products with the right application and technical support to help industries and auditors.

A few advanced T&M instruments

The offerings of Rishabh Instruments in the T&M instrument segment include basic power quality monitors like Rish PQM & RM 3440iDL, power quality analysers such as Rish PQA and advanced analysers such as ND45, NP40 & NP45 ideal for power quality analysis and audits.

Atandra Energy offers the following range of instruments and solutions:

• Class A Ed-3 Power Quality Analysers

• 4CT and 3CT Power Quality Analysers

• Power and Harmonic clamps

• Active Harmonic Filters

• Online Power Quality Panel Meters.

Recently, the need of power has been increased very high to meet the demand of consumers. Majority of the production lines have become automated which in turn increases the necessity of power. In order to meet this demand, power generation companies in India have been extensively working. However, such huge demand leads to power quality issues such as power loss, harmonic effects, voltage fluctuations in terms of swells, dips etc. To avoid or minimise power quality related issues, it is necessary to conduct a periodic maintenance activity in every power consuming facility, informed Prasanna Babu G, Manager – Business Development, Sonel Instruments India Pvt Ltd. T&M equipment such as power quality analyser, thermal image camera, corona camera etc., are used in testing activities.

Implementation of a good power quality measuring tool or device helps indicate the health of the system proactively to avoid future damage on the system.Good quality, reliable T&M instruments help one to take an informed decision on corrective actions to be taken.

Prabhakaran PV, Head – Product Management, Fluke India

Measuring power quality parameters, assessing their impact on sensitive equipment and adopting meaningful preventive measures is imperative for industry to ensure minimum downtimes.

R Mallikarjuna, General Manager – Power quality test and Measurement solutions, Atandra Energy

To avoid or minimise power quality related issues, it is necessary to conduct a periodic maintenance activity in every power consuming facility.

Prasanna Babu G, Manager – Business Development, Sonel Instruments India Pvt Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.