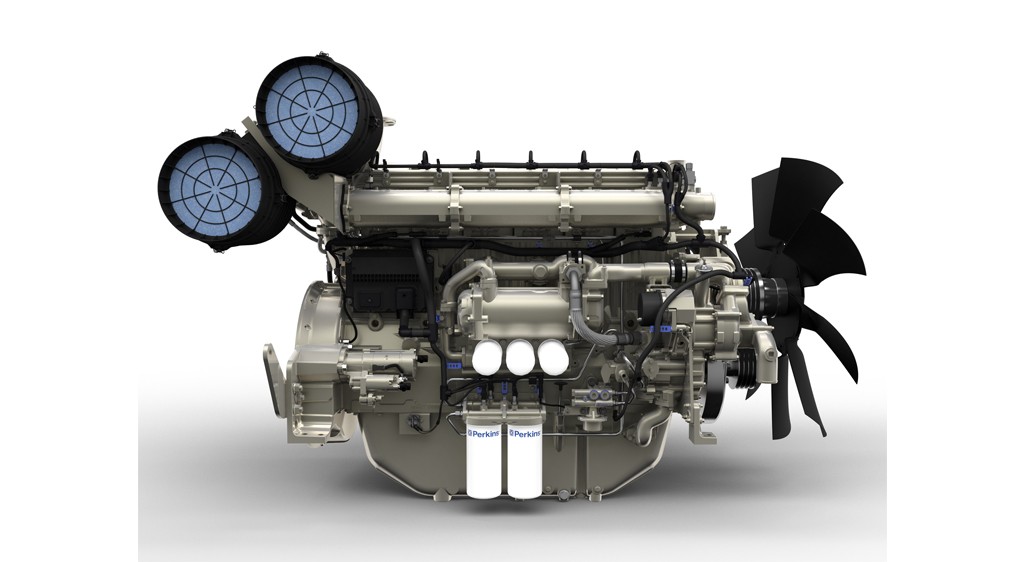

Perkins’ 4006 electronic engine for power generation

By EPR Magazine Editorial October 5, 2018 5:50 pm IST

By EPR Magazine Editorial October 5, 2018 5:50 pm IST

The Indian prime and standby power generation markets present some unique challenges for diesel engine suppliers including high ambient temperatures and high altitudes. Developing a market-leading engine that excels in these environments to offer durable and reliable power with excellent performance was the challenge accepted by the Perkins team.

“The 4006 electronic engine is a significant addition to the globally known Perkins 4000 Series range,” says Tommy Quan, Perkins Asia Sales Director. “By offering market leading performance and reduced cost of ownership, they are designed for the growing infrastructure industry of India; it is built on Perkins commitment to India.”

The new 6-cylinder, 23-litre 4006 electronic engine is rated at 750 kVA prime. It offers outstanding power density, simplified service requirements, world-class load acceptance and the ability to operate over a broad range of ambient temperatures and altitudes, all of which are important needs of the Indian power generation market. It is built on the core of Perkins 4000 series engines currently manufactured at Aurangabad with substantial improvements to many of that engine’s features.

A re-designed cylinder head benefits from changes in both materials and geometries that result in a tappet setting interval of 2,000 hours to reduce maintenance costs. The valves use new alloys in optimised designs and geometries to improve performance and extend their service life, resulting in a cylinder head top end overhaul period of 15,000 hours.

“Another step to improve uptime is through reducing engine oil consumption to minimise oil top up frequency,” Tommy added. “We addressed it with a new piston ring pack for the 4006 electronic that cuts oil consumption up to half. That’s another big reduction in operating and maintenance costs that impacts the overall cost of ownership for end users.”

While improved mechanical designs and components are important, the fact that the 4006 electronic engine is electronically controlled is the most significant change Perkins made to the product. Among the many benefits of this technology, is a reduction in specific fuel consumption of up to seven percent, resulting directly from the use of electronically controlled fuel injectors.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.