kVAH billing optimisation for highly dynamic loads in steel industries like EAF, rolling mills

By EPR Magazine Editorial January 3, 2024 4:07 pm IST

By EPR Magazine Editorial January 3, 2024 4:07 pm IST

The inPhase solution tackles high harmonics caused by non-linear loads and low power factors due to dynamic loads.

InPhase excels in addressing power system challenges in steel and other heavy industries. Steel industries incorporate dynamic loads like furnaces and rolling mills; conventional compensation needs to meet performance requirements. The company’s solution tackles high harmonics caused by non-linear loads and low power factors due to dynamic loads. Here is a case study of a customised solution implemented by InPhase for one of the leading steel manufacturers in India.

Major Loads:

Existing Conventional Compensators

Power Quality Issues:

Commercial Implications:

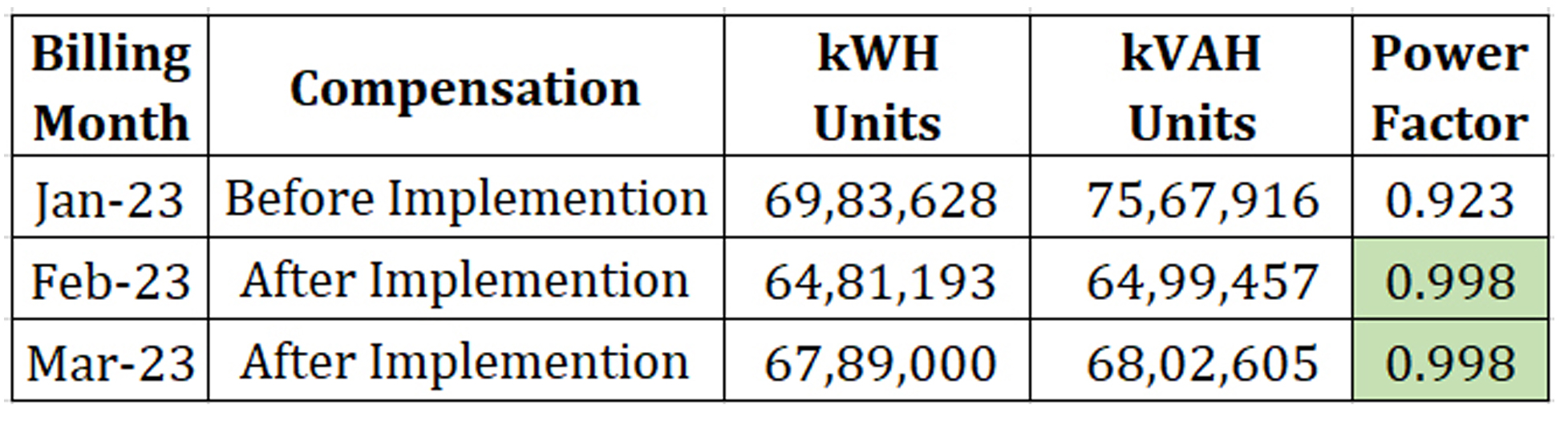

Since the inception of the kVAH billing methodology in Maharashtra in April 2020, the plant has been running at a low PF of 0.93. Due to this, they were paying higher electricity bills of 30 – 40 lakh rupees every month.

Implemented Solution:

Active Dynamic Reactive Power compensator

Incomer-1: +/-4700kVAR ASTRA

Incomer-2: +/- 2700kVAR ASTRA

The ASTRA panels are designed to improve PF at the metering point, taking direct CT feedback from 132kV Incomer.

Performance Achieved:

Note: Adding an Active Compensator to the existing HT/LT Passive PF correction system can provide additional fine-tuning capabilities. The Active Compensator can continuously monitor the power factor and dynamically inject or absorb reactive power to maintain a desired power factor.

Technical & Commercial Benefits Achieved:

Special Features of ASTRA:

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.