ABB India is enhancing Gas-insulated Switchgear (GIS) manufacturing with its state-of-the-art Nashik factory

By EPR Magazine Editorial June 26, 2023 1:26 pm IST

By EPR Magazine Editorial June 26, 2023 1:26 pm IST

Efficient power equipment manufacturing stabilises the energy grid infrastructure, says Sanjeev Sharma and Ganesh Kothawade of ABB India.

How has the power equipment industry evolved technologically over the past two decades?

Today, almost all of power equipment is becoming smarter with intelligent software and better emission control features making them safe and reliable. In electrical engineering, noticeable trends have emerged in recent years. Firstly, there is an apparent convergence between power systems and electronics and a growing emphasis on digitalisation. Approximately 80 percent of the electrical products manufactured today are increasingly expected to possess communication capabilities and be digitised. Consequently, there is a rising demand for these products to be connected to the cloud, enabling asset management. This represents a significant development in the industry.

Secondly, technology is undergoing significant changes, with a greater focus on producing environmentally friendly products. As a result, there is a shift towards using GIS (gas-insulated) switchgear, which takes up less space. This transition allows for a smaller footprint while delivering increased reliability and energy efficiency. Furthermore, the industry is witnessing a demand for products that are user-friendly and easy to operate. These transformations shape the market dynamics and drive advancements in the power equipment sector.

What challenges arise when integrating renewable energy into the grid for efficient distribution, especially in the context of solar power’s projected growth?

Previously, power would be generated at a large power station using lower voltage in traditional engineering. This power would then be elevated to a higher voltage for easier transportation. Transmission and distribution processes would follow, with the voltage being stepped down to deliver power to end-users geographically distant from the power generation source. These limitations existed in the past.

However, as the world increasingly embraces renewable energy and India makes commitments to reducing reliance on fossil fuels, there is growing support for renewable energy sources such as solar, hydro, and other clean forms of power. These energy sources generate power in a fragmented manner. Disturbances can occur when integrating these fragmented power sources into a unified grid. Our current grids may need to be fully prepared to handle this variability because renewable energy generation depends on natural factors. For instance, solar panels generate power during the day but not at night, and wind turbines rely on windy conditions. This fluctuating generation can destabilise the grid.

To address this challenge, power storage equipment becomes essential to stabilise the grid. The future lies in ensuring a stable grid by locally generating power and utilising it at the source. Any excess power generated can then be supplied to the grid. This approach allows for distributed power generation, emphasising local usage while maintaining grid stability. The transition towards this direction is evident as more entities move.

Please provide information about ABB’s newly inaugurated manufacturing facility for gas-insulated switchgear (GIS) in Nashik and its production capabilities.

ABB India recently celebrated the inauguration of a state-of-the-art Nashik factory dedicated to producing gas-insulated switchgear (GIS). This state-of-the-art facility has effectively doubled ABB’s GIS production capacity. The factory is equipped to manufacture primary and secondary GIS units, catering to a wide range of industries such as power distribution, smart cities, data centres, transportation (including metro and railways), tunnels, ports, highways, and other infrastructural developments.

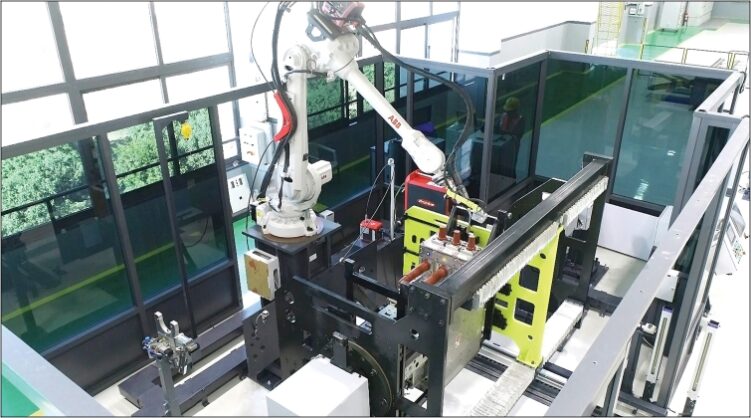

Spanning an area of 78,000 square feet, the new site boasts advanced and efficient manufacturing capabilities. It incorporates smart technology and employs lean manufacturing processes, integrating robotics to connect people, processes, and assets. This setup enables real-time data transmission, enhancing productivity. Moreover, the facility has been developed in compliance with the standards set by the Indian Green Building Council (IGBC), ensuring eco-friendliness. It optimises water and energy usage while employing carefully selected materials to minimise environmental impacts throughout its life cycle. In alignment with ABB’s Sustainability Strategy 2030 targets, the factory is powered by 100 percent renewable electricity, fulfilling the company’s commitment to low-carbon operations.

Nashik holds significant strategic importance for ABB India, with the inauguration of our first plant dating back 45 years. In 2018, we proudly unveiled our second manufacturing plant, and in February 2023, we inaugurated our third manufacturing facility in Nashik. Our focus on manufacturing electrical and electrification products continues to grow rapidly. Specifically, our Electrification Distribution Solutions division serves various market segments, including smart cities.

Furthermore, it is worth mentioning that this factory is the first in the switchgear industry to achieve a gold certificate from the IGBC. Our factory and its manufacturing processes have also been awarded platinum certification, highlighting our commitment to excellence.

Which products and solutions are designed and manufactured at your Nashik factory?

With the inauguration of this new factory, ABB India also launches PrimeGear™ ZX0 in the country. This eco-efficient switchgear is built on ABB’s SF6-free ecoGIS™ with Dry Air technology for applications up to 12kV in the factory in Nashik, supporting the migration to a greener, smarter and safer future. Its robust, compact design generates 20 percent less heat while saving energy and improving safety. Using SF6 alternatives, this ecoGIS™ lowers the global warming potential by 100 percent. PrimeGear™ ZX0 enables remote monitoring and reduces the product installation footprint by up to 25 percent compared to conventional switchgear. Being a market leader in GIS, this factory of ABB in India will strengthen local manufacturing and contributes towards creating a low-carbon society.

How do you evaluate India’s ongoing transition towards green energy through the emergence of electric vehicles?

While I don’t have expertise specifically in vehicles, it is clear that we are moving away from reliance on fossil fuels and embracing environmentally friendly alternatives. The shift towards renewable energy production is one significant step in this direction. Simultaneously, India is making remarkable progress in adopting electric vehicles (EVs). This is evident in the introduction of EV charging infrastructure by companies like ABB, which has become a significant and growing business globally. Although EV adoption in India may be less pronounced, it is expected that most vehicles, similar to the current trend in two-wheelers, will eventually transition to EVs. This will likely apply to four-wheelers, buses, and other modes of transportation. The future trajectory is undoubtedly oriented towards electric vehicles, as is evident in using green cabs for local transportation.

For more details, visit: https://new.abb.com/indian-subcontinent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.