Future-proofing flexible Wärtsilä engine power plants

By EPR Magazine Editorial June 6, 2022 12:41 pm IST

By EPR Magazine Editorial June 6, 2022 12:41 pm IST

Current Wärtsilä gas engine power plants can use up to 25 percent hydrogen blends in natural gas and we are developing a concept for pure hydrogen operations to be launched in 2025.

In order to meet decarbonisation goals and limit the impacts of climate change, national power systems should obtain 100 percent renewable power generation in future. Renewable like solar and wind will be required in abundance. To balance the intermittent nature of these renewable power sources, engine power plants and energy storage are ideal.

Wärtsilä power plants can already now run on carbon neutral fuels, and we will have solutions available for new sustainable fuels as those become available both for new power plants, and for conversions of existing assets. Wärtsilä’s continuous research on future fuels and engine technology will ensure reliable power generation with a wide range of sustainable fuels.

Current decarbonisation debates, which frequently focus on CO2 and other pollutants affecting local air quality, are generally ignored. However, both local and global emissions must be considered and a balance struck. Even carbon-free fuels like hydrogen or ammonia may not produce zero emissions, and depending on how emission limitations are enforced, exhaust after treatment, such as NOx reduction, may be required.

Modern and flexible engine power plants, as previously said, are a suitable alternative for balancing power because of their versatility in terms of fuels and operation profiles. Batteries alone will not be able to meet the balancing demands of variable renewable energy sources. Flexible capacity must be capable of starting rapidly at any moment and ramping up and down an unlimited number of times per day. Wärtsilä engine power plants can connect to the grid in less than 30 seconds and reach full load in less than two minutes. With such rapid ramp-ups, less gasoline is consumed during startup, resulting in lower set-up emissions.

There are benefits of having multiple medium-sized power plant units when dynamic power output levels are required. By switching the units off and running the remaining units at highest efficiencies, overall fuel consumption and CO2 emissions are minimised.

Current Wärtsilä gas engine power plants can use up to 25 percent hydrogen blends in natural gas and there is ongoing development for pure hydrogen and other P2X fuels. A fuel change can entail changing the combustion parameters of the engine, and therefore can potentially change the output. With hydrogen blends it is expected that it doesn’t impact the component’s lifetime, nor does it impact the frequency of maintenance. Selection and testing of new materials and components are ongoing for the various P2X fuels concepts. Additionally, the life cycle aspects remains to be a vital part of that development.

Wärtsilä is working on future fuel development according to its initial timetable

There are good synergies between the Wärtsilä Energy, and the Marine business units in fuel development needs; and Wärtsilä is testing and validating engines and the new solutions for both markets.

There are good synergies between the Wärtsilä Energy, and the Marine business units in fuel development needs; and Wärtsilä is testing and validating engines and the new solutions for both markets.

Wärtsilä continues developing hydrogen power plant solutions and will launch a power plant design for hydrogen blends in 2022, along with a concept for pure Hydrogen in 2025.

Proven track record in conversions

Power producers have always been concerned about their existing fleets becoming stranded assets due to changing market conditions and new fuels becoming available. The transition from carbon-intensive fuels, e.g., coal or HFO, to natural gas is a significant improvement step.

Decarbonisation can already be further enhanced by utilising blends or pure biofuels. If the conversion is made to dual-fuel engines, they can use an even wider range of fuels. For dual-fuel engines, a switch between liquid fuel and gas can be effortlessly made when the new fuel becomes available locally.

Conversion, usually is a more economically viable way to implement future fuels, than making Greenfield investments. Wärtsilä will have conversion packages for hydrogen engine power plants, along with the capability to develop ammonia and methanol conversions as and when required. The current understanding is that the majority of the engine will remain unchanged, while the fuel supply and control systems will be impacted.

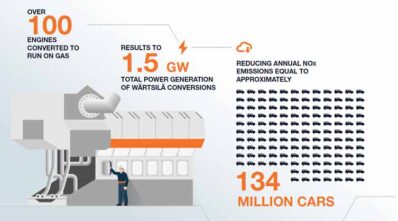

Wärtsilä has an extensive track record of optimisations and conversions to new fuels for existing assets. Globally, they have converted over 100 engines from HFO to gas-based operations. The main drivers for conversions from liquid fuels to gas have been the reduction of operational costs, local and GHG emissions. Local NOx emissions are reduced by 80-90 percent, and as natural gas contains almost no sulphur or ash, SOx and PM emissions are very low. The GHG emissions are reduced by 10- 15 percent. By converting from HFO to natural gas, power producers can become more competitive and meet new emissions regulations. This can further ensure that they can continue to operate and get a return on their investment despite a changing business environment.Key factors impacting the switch to sustainable fuels for Engine Power Plants

Wärtsilä collaborates with customers, suppliers and research institutions

Wärtsilä has constant deliberations with their customers to utilise sustainable fuels in Greenfield projects; and to evaluate fuel blends or fuel conversions for existing assets. Wärtsilä is committed to support its customers to move forward on their path to decarbonisation.

As part of the strong green hydrogen boom Wärtsilä is planning several hydrogen projects with partners and customers ranging from utilising hydrogen blends in existing assets at customers to a P2X2P plant in collaboration with partners.

For maritime sector, Wärtsilä is currently installing and commissioning the first ammonia pilot dual-fuel engine in Norway. Its methanol- fuelled engines have powered the Stena Germanica ferry since 2015 and in 2021 the methanol engine solution including fuel storage and supply system (MethanolPac) has been launched.

Wärtsilä has invested heavily in its development and production facilities during the previous years. Later in 2022 there will be the grand opening of the Wärtsilä Smart Technology Hub in Vaasa, Finland. Together with both internal and external partners, Wärtsilä Smart Technology Hub is a collaboration ecosystem both on local and global level. It connects companies, startups, organisations and academia in developing future sustainable societies.

Fuel testing and engine development will continue throughout the coming years. They are there to enable the transition to a decarbonised future with innovations in fuel flexible technology and decarbonisation services.

For more details, please contact: Dr. Reetta Kaila, Director,

Sustaina stainable Fuels and Environment

Email: reetta.kaila@wartsila.com

Fredrik Östman Product Manager, Fuel Conversion and Decarbonisation

Email: fredrik.ostman@wartsila.com Website: www.wartsila.com/energy

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.