Powering pharmaceutical with solar

By EPR Magazine Editorial January 9, 2020 12:08 pm IST

By EPR Magazine Editorial January 9, 2020 12:08 pm IST

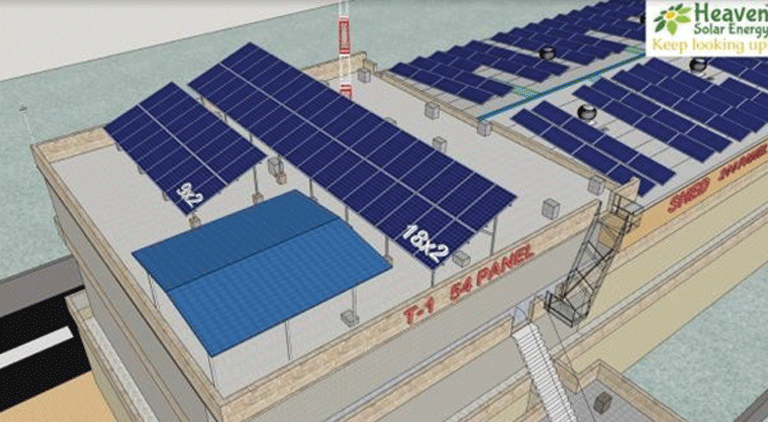

Designing a complete 3D model of factory site and simulating whole project in a software, while installing the solar plants on its TIN shed roof.

In today’s cut-throat competitive market, delivering a good quality product at an affordable price is a big challenge. We closely work with many solar EPC companies as their design partners. To deliver a cost-effective and energy-efficient solution solar project design plays a very important role. Every site comes with a new unique challenge and new opportunities that excite us more.

One of our pharmaceutical industry owners from Vadodara wanted to go solar. He has an average consumption of electrical energy of 33,300 kWh per month which costs him approx ₹ 2.5 lakhs per month and he noticed a continuous increment in energy charges every year, and finally, in June 2019 they decided to install solar panels on his pharma factory.

We met the client to understand their exact needs and did a detailed discussion. In conclusion of the meeting we found the following major challenges:

After realising these challenges, we visited the site. The rooftop of the industry was basically divided into two parts:

To meet the above challenges, we worked on the selection of technology, project feasibility. We found that there are ventilators and few other objects which will cast a shadow on solar modules in the morning and evening time for a few months of winter. For us, each ray of sun is very important and we wanted to get maximum radiation on solar panels.

TIN shed of factory RCC building of the factory

To get maximum generation we can use MONO PERC panels, which requires less space and produce more energy at the same time. MONO PERC modules cost a lot more. We studied the detailed datasheet of solar cell and choose modules in polycrystalline technology and fill factor of 79 percent. Poly 325-watt modules were good enough, in terms of both cost-wise and efficiency-wise.

Now the concern was space. Poly panels occupy more space, and will cover almost complete RCC roof and TIN shed roof. The customer did not agree to cover the entire RCC roof; they wanted some space for future construction on RCC. Though it was a minor shadow, we did not want to install solar panels in the shadow region on the TIN shed, because, we know that it affects the generation of an entire row of panels which was definitely going to increase the ROI time.

Heaven’s EPC team Heaven’s design team3D design and real Installation

Finally, the project got installed as per the drawings and commissioned recently. Our team inspected the site and verified the electrical parameters. The plant is working as expected and hopefully, ROI will be done before 3.75 years. This project helped us to build stronger business relations with our client EPC company.

Project summary

No Solar power plant size 126 KW On grid

Visit us at

www.HeavenSolarEnergy.com

Email: Design@HeavenSolarEnergy.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.