Preventing electrocution and electrical fires

By Staff Report May 8, 2025 11:41 am IST

By Staff Report May 8, 2025 11:41 am IST

According to the National Crime Records Bureau, around one lakh people lost their lives because of electrocution in the last decade alone.

Electrocution, electrical fire and lightning kill 15,000 a year. Also 75000 (approx.) suffer because of these deaths, there is loss of property and assets, dreams of many people associated with deceased shatter. Around 1 lakh people died due to electrocution in the last decade, as per NCRB data.

NCRB data of deaths due to lighting electrocution and short circuit fire 2020-2022

According to the National Crime Records Bureau, around one lakh people lost their lives because of electrocution in the last decade alone. The annual average of fatalities rose to 12,500 per year or 30 fatalities every day.

Causes of electrocution and electrical fire hazard

Electrocution and electrical fires in electrical installations can result from various issues such as over currents caused by overloads or short circuits, presence of harmonics, and earth faults. Electric arcs in cables, loose connections and failure or incorrect selection of protection devices also pose significant risks. Additional causes include improper cable selection, mismatched lighting components, misuse of extension cords for heavy loads, and outdated or damaged equipment. Over voltages, inadequate earthing design, and lack of proper testing or verification further contribute to these hazards.

Role of adequate earthing/grounding

Grounding/earthing means making a connection to the general mass of earth. The use of grounding is so widespread in an electric system that at practically every point in the system from the generators to the consumers’ equipment, earth connections are made.

There are two types grounding:

Equipment and neutral earthing

The objectives of general grounding system

The general grounding system serves multiple critical objectives within a power system. It provides a low-resistance return path for fault currents, ensuring the safety of personnel and protection of equipment. By minimising ground potential rise (GPR) during faults, it prevents hazardous voltage differences with respect to remote ground. It also offers a safe discharge path for power system transients like lightning and over voltages. Additionally, the system ensures uniform potential bonding of conductive objects within a substation, reducing the risk of dangerous potential differences. It further prevents electrostatic charge buildup and allows sufficient fault current flow for proper operation of protection systems.

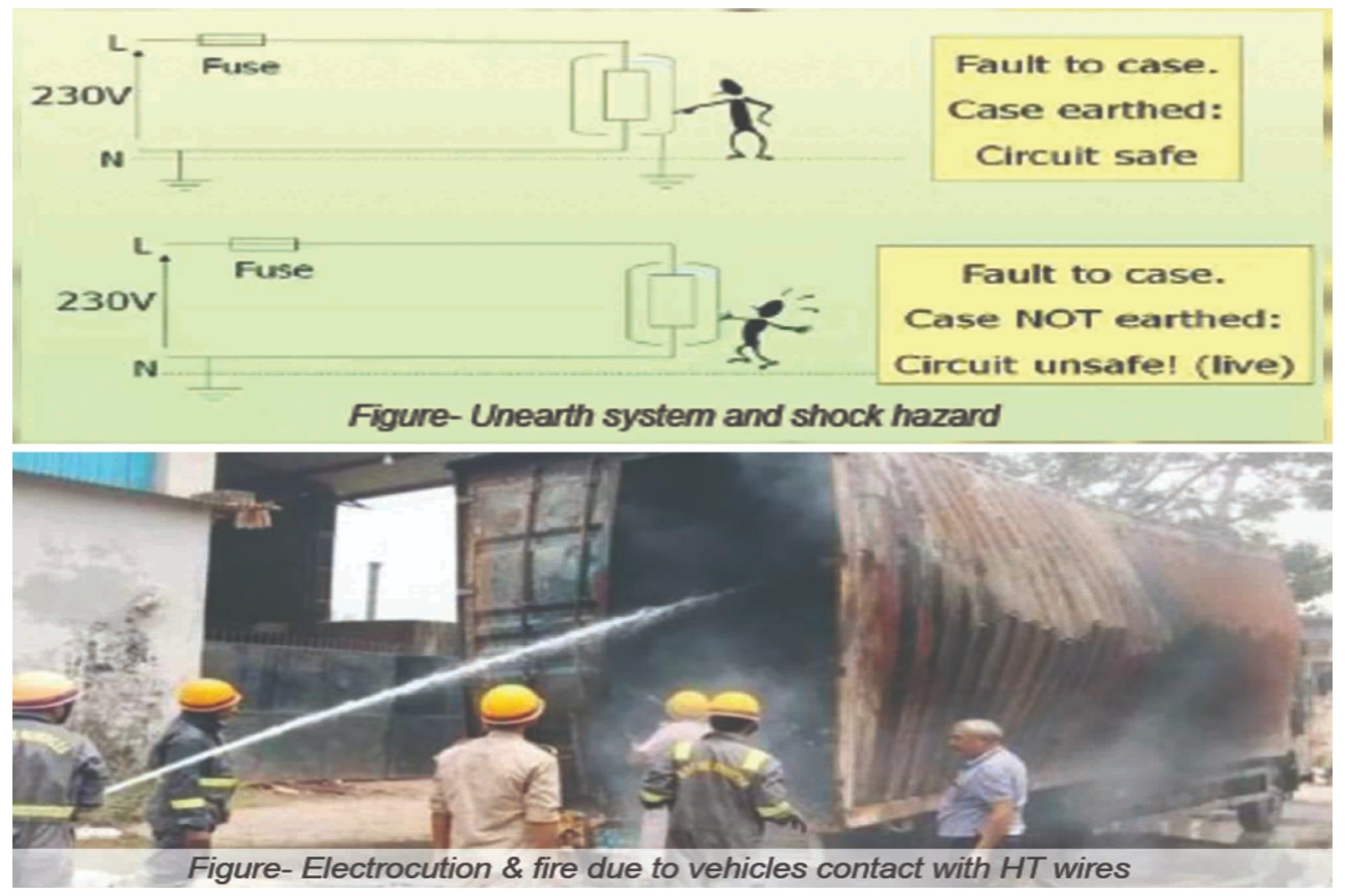

Unearth system and shock hazard

The main objective of grounding electrical systems is to provide a suitably low resistance path for the discharge of fault current which ultimately provides safety to working personnel and costly installed equipment by providing sufficient current to safety devices.

Electrocution due to high-tension wires

Inadequate clearance: Temporary structures erected for public processions often lack proper planning and supervision, resulting in insufficient clearance between the structures and overhead high-tension wires. Failure to maintain adequate distance increases the risk of accidental contact, especially when structures sway due to wind or crowd movement.

Ignorance and negligence: Organisers and participants may lack awareness about the dangers posed by high-tension wires or fail to recognise the potential hazards associated with erecting structures near them. Ignorance coupled with negligence in adhering to safety guidelines exacerbates the risk of electrocution incidents.

Lack of coordination: Coordination between event organisers, local authorities, and power distribution companies is often inadequate, leading to haphazard planning and implementation of safety measures. Failure to coordinate activities such as route planning, structure placement, and crowd management increases the likelihood of accidents involving high-tension wires.Encroachment and unauthorised construction: Encroachment on public spaces and unauthorised construction near high-tension wire corridors is a common phenomenon in many Indian cities and towns. Informal settlements, temporary shelters, and makeshift structures often encroach upon the safety buffer zones around high-tension wires, heightening the risk of electrocution during public processions.

Electrical safety at industrial location, generating station and substations

Industries, generating station and substations are critical components of electrical networks, but they also pose significant risks if safety measures are not strictly enforced.

Causes of electrocution and fire in substations include:

High voltage exposure: Industries and substations contain high-voltage equipment that poses a severe risk of electrocution to untrained personnel or trespassers who come into contact with live components.

Equipment failure: Malfunctions or breakdowns of transformers, circuit breakers, and other substation equipment can result in electrical arcs, sparks, and fires.

Lack of proper enclosure: Unprotected or poorly enclosed panels or substations may expose electrical components to environmental factors such as moisture, debris, and wildlife, increasing the risk of failures and fires.

Inadequate security measures: Substations that lack sufficient security measures are vulnerable to unauthorised access, which can lead to tampering, theft, or vandalism that compromises safety.

Insufficient training: Workers at factories or substations must receive comprehensive training on electrical safety protocols and emergency procedures to mitigate risks effectively.

Golden rules to ensure safety

To ensure safety at industrial locations, substations or generating stations, follow these seven golden rules. Begin by thoroughly evaluating the task and conducting an on-site Hazard Identification and Risk Assessment (HIRA). Clearly identify the work location and the specific equipment involved. Apply for a permit to work and review the job details with the team. Disconnect electrical sources and secure them against reconnection using Lockout-Tagout (LOTO) procedures. Always verify the absence of voltage before starting work. Ensure proper earthing of the equipment being serviced. Finally, protect adjacent live parts and exercise extreme caution when working near bare conductors.

Conclusion

Regular maintenance and condition monitoring of electrical equipment are essential to prevent hazards. Routine inspections by qualified electricians ensure early detection of faults. Proper wiring, adherence to safety standards, and the use of overload protection devices like circuit breakers are crucial. Fire safety measures, including smoke alarms and extinguishers, must be in place. Keep electrical setups ventilated and clear of obstructions. Promote awareness about safe practices, especially during rain, waterlogging or public events. Emergency preparedness and lightning protection are vital. By taking these steps, we can reduce risks and ensure safety.

Authored by: Dr. RAJESH KUMAR ARORA Senior Manager Delhi Transco Limited .

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.