Sterlite Power delivers reliable power to over 3 Cr residents in Northeast India

By EPR Magazine Editorial December 5, 2020 10:37 am IST

By EPR Magazine Editorial December 5, 2020 10:37 am IST

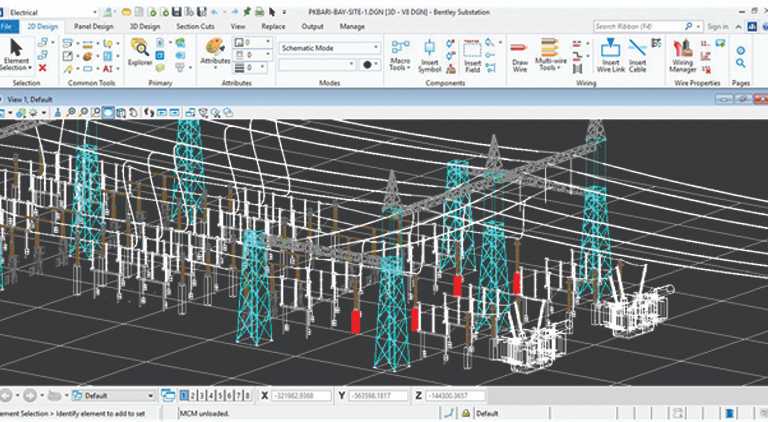

The company Sterlite Power overcame inefficiencies of conventional design and construction modeling methodologies with 3D and 4D BIM technology to enhance visualisation, collaboration, and efficiency

Project Overview

India is strongly commitment to its renewable energy targets, which are aimed at quickly reducing carbon emissions. The North Eastern Regional (NER) Grid of India, serving a population of more than 3 crore, wants to improve reliability of power evacuation, reduce intermittency, and accelerate sustainability of renewables for this region. The Power Ministry awarded Sterlite Power, a developer of power transmission infrastructure projects, the NER-II Transmission Limited project to develop transmission lines across the region. Sterlite Power is an established technology leader in this sector and a sponsor of India’s first power sector Infrastructure Investment Trust.

The project is of strategic importance to India’s renewable energy targets. It strengthens interconnection with the states of Assam and Arunachal Pradesh and provides an additional source of power to the capital city of Itanagar. However, the project was complex, including designing and constructing a 400-kV/132-kV substation in Tripura state to evacuate gas-generated power from ONGC’s Palatana power plant (a 726.3-MW combined-cycle gas turbine). The substation was the only one delivering much-needed power to Tripura state. Considering the importance of this substation for the local region, efficient design and construction of a new substation within a tight schedule were necessary for rigorous project monitoring and real-time construction updates. Seamless and accurate information flow among stakeholders was crucial to ensure timely delivery of the substation.

Challenge

Sterlite Power realised that they needed a modeling solution that would deliver right-first-time design by detecting and resolving clashes early in the design process. However, traditional 2D design methods for substation planning limited the design team’s ability to detect clearance problems between electrical components and support structures. Additional challenges included managing interdependency among activities, design-plan inter-linkage, a lack of real-time progress data, and inefficient resource planning. These inefficiencies posed enormous risks in the substation construction timeline adding prolonged inspections, handovers, and resource training difficulties. Therefore, 3D modeling proved to be the best method.

Adopting BIM 4D technology using SYNCHRO also helped Sterlite Power utilise virtual reality to further optimise and refine design and planning. They generated a detailed reality model from images captured with unmanned aerial vehicles, which helped them further optimise substation layout and increase design and planning efficiency.

“With Bentley’s ProjectWise, our project team was able to work in complete collaboration, even when separated by distance,” said Pratik Agarwal, Managing Director, Sterlite Power. “Design being the heart of infrastructure projects, the application’s real-time review system helped us save huge hours of reworking on design errors and enabled us to accelerate the renewable energy journey of India.”

Outcome

Using OpenUtilities Substation, Sterlite Power was able to check for electrical clearance issues and detect problems early in the design process, which helped them reduce rework. They saved nearly Rs 23 lakhs and over a month on the project schedule. The cost and time savings can be attributed to a reduction in design closure time through enhanced collaboration and a digitalised workflow using a connected data environment.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.