OPTICHECK™ technology built-in for OPTIMASS

By Staff Report May 28, 2025 12:15 pm IST

By Staff Report May 28, 2025 12:15 pm IST

Built-in OPTICHECK™ technology enables advanced diagnostics, verification and functional safety in OPTIMASS Coriolis mass flowmeters, ensuring reliable and efficient flow measurement.

Introduction

State-of-the-art measuring devices such as OPTIMASS Coriolis mass flowmeters combine robust measuring principles and powerful electronics to produce a wide range of readings and device-specific data. OPTICHECK technology built-in leverages the features of the devices to translate their available comprehensive measuring system data into sophisticated diagnostics information for plant personnel.

It goes beyond extensive device diagnostics, self-tests and on-site verification. With measurement principle-specific application diagnostics, this technology also allows in-depth insights into the process and thus opens far-reaching possibilities for device monitoring, condition-based maintenance and optimisation of measurement technology and systems.

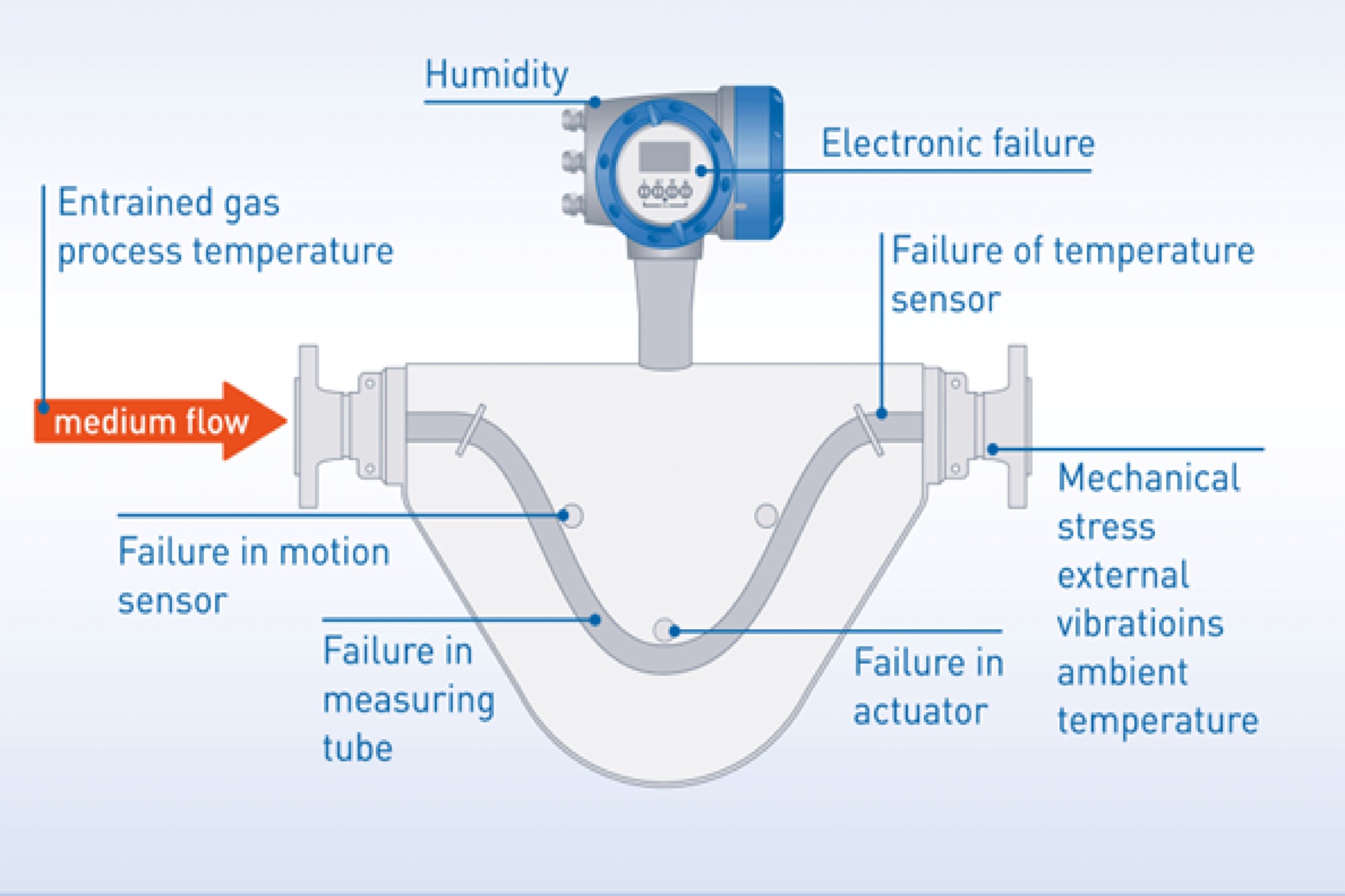

The functional status of a measuring device can have a direct influence on the reliability of a measurement and therefore on process stability and system availability. The comprehensive device diagnostics from OPTICHECK technology built-in enable a measuring device to reliably detect typical errors or potential damage within the meter’s sensor or signal converter. OPTICHECK technology built-in produces a continuously repeating self-diagnosis of the measuring device resulting in reliable self-monitoring of the meter’s health for every moment it is in operation.

Continuously repeating self-diagnosis

Every measuring device with OPTICHECK technology built-in can provide a reliable statement about the correct function of the device at any time. The technology uses continuously executed test routines to cyclically compare the current device condition against its baseline performance at time of delivery. In addition to the general monitoring of output signals, power supply and circuits, this includes numerous device-specific function tests.

Diagnostics of OPTIMASS Coriolis mass flowmeters include

On-site verification with report generation at the touch of a button

For the operator, the permanent self-monitoring is translated into standardised status signals in accordance with NAMUR NE 107. These status signals provide clear and comprehensible descriptions of the current device situation and provide a quick overview of error events. The error information can be immediately signalled to the control room via a defined error current or via error signals. This provides operators with condition-based information about the measuring devices in real time. Appropriate measures can be derived from this. All data is also logged in the measuring device and, in case of doubt, is available for a more in-depth root cause analysis.

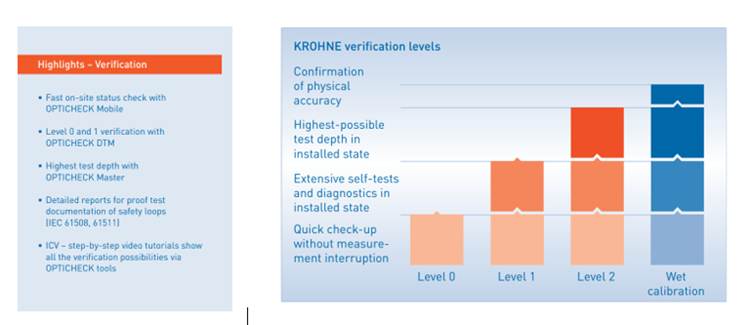

The continuously running self-diagnosis of OPTICHECK technology built-in also forms the basis for rapid on-site verification of the measuring devices. Regardless of whether the status of software and hardware components is to be routinely checked and documented or carried out as part of troubleshooting, detailed verification reports on the health status of the instrumentation can be generated directly on site or in the control room.

The measuring devices can be checked without interrupting the process and are ready for reporting at the touch of a button. Depending on the device type, this verification option can be performed wirelessly via Bluetooth using the OPTICHECK Mobile app on site at the field device or from the control room using the OPTICHECK DTM.

Built-in application diagnostics

In addition to comprehensive device diagnostics, OPTICHECK technology built-in provides a wide range of device-specific application diagnostics that provide a deep insight into your own processes and systems. This measurement and device data is always available to operators to optimise and control processes. They also provide information that can be used for predictive system maintenance. OPTICHECK technology built-in utilises the device-specific data in numerous KROHNE measuring devices for meaningful application diagnostics.

Advantages of OPTICHECK technology built-in:

Colour coded display and user interface.

Diagnostics functions in the OPTIMASS MFC 400 converter can be displayed according to various standards: VDI / NAMUR NE107 and WIB 2650. The status messages have the option to be shown via display, current and/or status output, HART® or bus interface.

The backlight colour displays device status according to NE107.

myDevice – Smart Service Tools

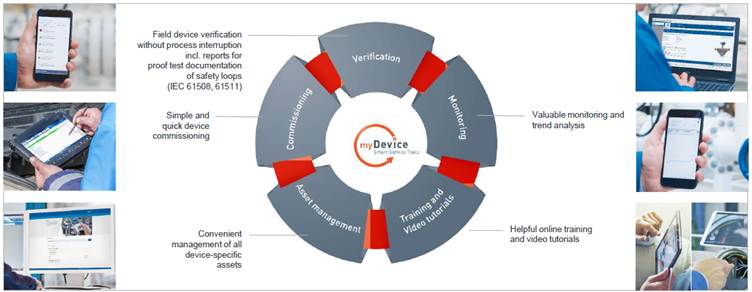

The myDevice tool suite is tailored to meet the needs of users and operators of KROHNE process instrumentation.

The comprehensive range of smart service tools makes it easy to commission, verify and monitor devices in the field and provides convenient access to all device-related assets. A training and tutorial portfolio for streaming and downloading rounds off the suite to help you resolve questions about process instrumentation.

myDevice covers the entire lifecycle of a measuring point

myDevice tool suite at a glance

Verification, device commissioning and monitoring options for OPTIMASS flowmeters

OPTICHECK Master

Handheld for in-depth verification, device commissioning and monitoring

OPTICHECK Master is a handheld for in-depth verification, commissioning and monitoring of KROHNE field devices. It provides the most extensive on-site device verification available on the market. Featuring the highest possible test depth, this essential service tool ensures that process measuring devices perform according to specification. In this way, operators can extend the time between costly re-calibrations of field devices.

Product features and options depend on device configuration: Contact us to make sure that your preferred functionality can be combined in one device.

OPTICHECK DTM

DTM for advanced device verification and commissioning

OPTICHECK DTM is a device type manager (DTM) for verification as well as commissioning of KROHNE measuring devices. It can be either used on site or from a control room. The tool provides advanced verification with full access to the powerful diagnostic functions of a field device. Operators benefit from extensive performance checks with precise status information on each device. The service life of measuring instruments can be increased while life-cycle costs can be reduced. In addition, detailed reports, e.g. for proof test documentation of safety loops (acc. to IEC 61508/61511) as well as for quality management systems (acc. to ISO 9001), can also be generated.

Product features and options depend on device configuration: Contact us to make sure that your preferred functionality can be combined in one device.

OPTICHECK Mobile

Mobile app for wireless device commissioning, verification and monitoring

OPTICHECK Mobile is a mobile app for wireless on-site commissioning, verification and monitoring of KROHNE measuring devices. It is the ideal service tool to manage all device settings via a secure Bluetooth connection. In this way, a variety of commissioning tasks, e.g. zero calibration or configuration of diagnostics, can be done wirelessly. The mobile app also enables thresholds for certain parameters to be set and adjusted via a mobile device.

Product features and options depend on device configuration: Contact us to make sure that your preferred functionality can be combined in one device.

General

Does verification replace calibration?

Verification ensures that the flowmeter is operating within its original manufacturing specification whereas calibration is comparing the accuracy of the flowmeter to a device which is more accurate than the flowmeter itself. Verification can be performed without removing the flowmeter from the line whereas calibration usually requires the flowmeter to be removed from the line (unless a mobile prover or similar is used).

No integral flowmeter verification can replace national, industry or institutional requirements for calibration or re-calibration. Some mandate periodical wet calibration of the flowmeter, and the end user is responsible to fulfil this legal requirement. While verification can extend the time required between calibrations, it does not replace it.

Functional Safety and SIL

Functional safety is a crucial part of plant safety in the process industry. To ensure plant safety, most plant operators follow IEC 61508/61511. These rules and standards provide normative guidelines for ensuring the safe operation of process equipment. KROHNE supports its customers with measuring solutions and advice on plant safety.

Definition of Safety Integrity Levels

SIL stands for Safety Integrity Level and indicates the safety level on a device. The standards set out four safety integrity levels for minimising the risks of equipment. For example, a safety function designed in accordance with SIL 1 reduces the plant risk by a factor of 10-100, a function designed in accordance with SIL 2 reduces the plant risk by a factor of 100 – 1000, etc

A safety function (SIS – Safety Integrated Function) as per IEC 61508 essentially consists of three components:

Criteria for the design of safety functions

The safety integrity level is defined by the plant operator in a risk assessment (HAZOP). Two criteria must be fulfilled for the safety function to be configured properly (e.g. as per SIL 2):For example: the overall failure probability of an SIL 2 safety device must not exceed 0.01 per year, i.e. mathematically the safety functions must fail less than every 100 years.

What the SIL logos mean

In the example shown here, which applies to OPTIMASS flowmeters with the SIL-enabled MFC 400 converter, this means that the hardware of the field instrument is certified in SIL 2, whereas the software is certified in SIL 3. Thus, these devices can be used in a single channel (1oo1) in SIL 2 and in two channels (1oo2) in SIL 3 applications.

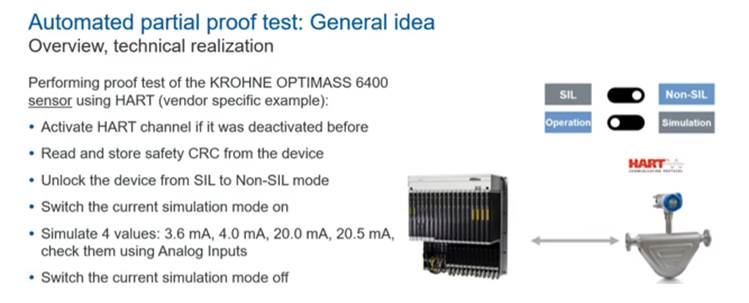

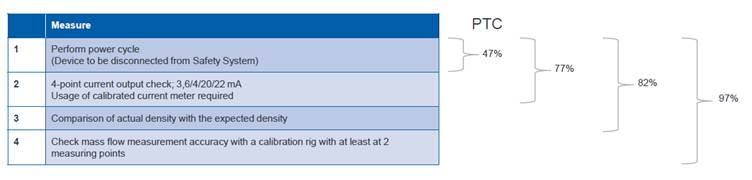

Automated partial proof testing

Partial proof testing in general offers great opportunities to increase overall plant safety and the reduction of proof test efforts.

OPTICHECK technology built-in offers added value during automated partial proof testing in safety-related applications. In the partial proof test, it enables a complete self-test to be carried out, which allows a proof test coverage (PTC) of up to 80percent and a failure detection rate of approx. 95percent, ensuring the safe operation of any safety-relevant function. This can also extend the interval between full tests under certain conditions.

Both full proof test and a partial proof test procedures have been developed in conjunction with TÜV Rheinland for KROHNE’s OPTIMASS Coriolis flowmeters. Proof test coverage (PTC) of up to 82percent is available without the need to remove the device from the process line. This ensures the safe operation of any safety-relevant function involving Coriolis flow measurement and helps to lengthen full proof test intervals.

In addition, the test methods themselves are now also fully automated. For this purpose, the safety system (SSPS) first reads out the entire configuration of the measuring device while in SIL mode. Then the safety control system (SSPS) transfers the measuring device from SIL mode to simulation mode to perform the specified partial proof tests:

Conducting a complete self-test

First, the SSPS causes the device to perform a complete self-test. In doing so, the device can test memory areas, among others, that it could not be tested in normal operation. Depending on the measuring method, this self-test can reach a test depth (PTC – Partial Proof Test Coverage) of up to 47percent.

Easy testing of current loops

Secondly, the current loops can now be easily tested without disconnecting the cabling. Via simulation, the SSPS instructs the measuring device to apply different current values to the output, which are measured directly by the input modules of the SSPS. This makes it easy to check whether the setpoint and actual values still match. Depending on the device type, the PTC here is approx. 30percent, so giving approx. 77percent total.

Density comparison

Comparison of actual density against the expected (measured) density extends the PTC to approx. 82percent.

At the end of the automated partial proof test, the measuring device is set back to SIL mode, and the previously read configuration is compared with the current configuration. This is done to ensure that the device is 100percent in the same configuration state as before the test.

Important: The plant operator must be aware that during the partial proof test, manually performed or automated, the safety function is not available for the duration of the test!

It is essential to ensure that the safety of the plant operation is guaranteed during the partial proof test. This is usually regulated by organisational measures: If, for example, there is a risk of overfilling a container, which could result in persons in the immediate vicinity being burned, the corresponding area must be closed off to persons for the duration of the partial test.

Partial proof tests bring a test coverage of up to 80percent of all undetected failures by self-diagnosis. They ensure the safe operation of any safety-relevant function and can be carried out under process conditions – no need to remove the device from the process.

Additional testing for Full Proof Test Coverage

Calibration of the device with a more accurate device based on a minimum of two measuring points to confirm mass flow measurement accuracy can take the PTC to approx. 97percent.

Entrained Gas Management (EGM)

EGM was developed for OPTIMASS Coriolis mass flowmeters to overcome problems caused by air or gas entrainments in a liquid. Powerful control algorithms allow the flowmeter to maintain operation over a wide range of gas fractions and complex flow conditions, even during a complete transition from a pure liquid phase to a gas phase and back. Mass flow and density measurements remain stable and continuous, which has been demonstrated in batch/ loading/ empty-full-empty applications.

EGM™ (Entrained Gas Management) is a standard feature on all OPTIMASS flowmeters with MFC 400 converter.

Entrained gas – required or unwanted?

Entrained gas may either be required for the process or the product (e.g. with aerated products) or occur as an unwanted side-effect caused by:

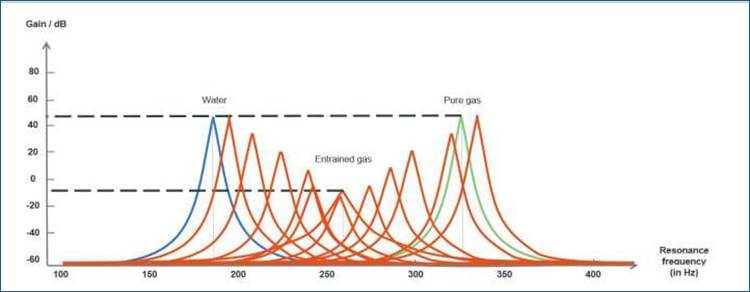

How entrained air or gas affects the Coriolis flow measurement

With conventional Coriolis mass flowmeters, difficulties arise with entrained air or gas in the liquid, e.g. overreporting, or maintaining measurement. This is because the entrained air or gas affects the measurement.

Without entrained gas, the measuring tubes in the Coriolis mass flowmeter have the desired

regular oscillation. Gas entrained in the liquid dampens this regular oscillation, and as the gas content increases, the oscillation can come to a complete stop.

To overcome this, KROHNE has developed powerful control algorithms for the OPTIMASS series of Coriolis flowmeters and implemented them in a synthesised drive control.

Continuous operation even with complex flow regimes

The difficulty of measuring a liquid with entrained gas increases with the gas volume fraction (GVF). Several other process factors such as temperature, increased viscosity, pressure, and the relative velocity between liquid and gas also affect the resulting flow regime.

EGM technology allows the flowmeter to maintain the oscillation with complex flow regimes. Even during a complete transition from a pure liquid phase to a gas phase and back, i.e. from 0 to 100percent gas content, the device will continue to operate.

Benefits

EGM technology presents several advantages for your process:

Mass or density measurement – both are possible even with gas entrainment

Density measurement of single-phase fluids is common practice, but for traditional meters it becomes challenging with entrained gas. In many applications where entrained gas is present, OPTIMASS flowmeters with EGM show excellent performance and repeatability for process control, batching, loading, unloading and transfer measurement.

KROHNE Centre of Excellence for Mass Flow Technology

The KROHNE centre of excellence for Coriolis mass flowmeters is located in Wellingborough in the United Kingdom. KROHNE launched the first commercially available single straight tube Coriolis meter and holds many patents that make possible the natural evolution of unique designs.

KROHNE has almost 4 decades of experience in developing the most innovative Coriolis meters. Our state-of-the-art R&D and manufacturing facilities are focused on continuous improvement of the product design & quality. Ongoing research and development play a crucial role in shaping and innovating the evolution of the OPTIMASS range. Each product is continually tested to global standards, to provide highest possible product excellence and reliability. Beside R&D and production we attach special importance to pre and post sales customer support, with in-house, on-site and remote training available.

The OPTIMASS series includes a complete portfolio of Coriolis mass flowmeters for mass, volume flow, density and concentration measurement of liquids and gases. Sizes range from DN01 to DN400 (1/25″ to 16″)with a wide pressure range and temperature range from -200°C to 400°C (-328F to 752F). KROHNE provides superior mass flowmeters with straight and bent tube designs to suit all applications.

Authored by:

Richard Davison, International Product Manager for Mass Flow – KROHNE Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.