Extending substation automation systems during operation

By EPR Magazine Editorial November 11, 2020 4:29 pm IST

By EPR Magazine Editorial November 11, 2020 4:29 pm IST

This article describes an innovative method for testing the substation automation system functions, especially for the expansion of a substation during operation and for commissioning bay by bay.

Extension and testing of a substation – automation system with interlockings based on IEC 61850

The international standard IEC 61850 (communication networks and systems for power utility automation) allows the implementation of interlockings and backup protection functions by means of real-time communication instead of copper wiring of signals. This article describes an innovative method for testing the substation automation system functions, especially for the expansion of a substation during operation and for commissioning bay by bay.

IEC 61850 was published in the early 2000s and is now a recognised standard for automation systems in substations. With Edition 2 [1] and the now available Edition 2.1, its acceptance has grown and its implementation in all countries continues to increase.

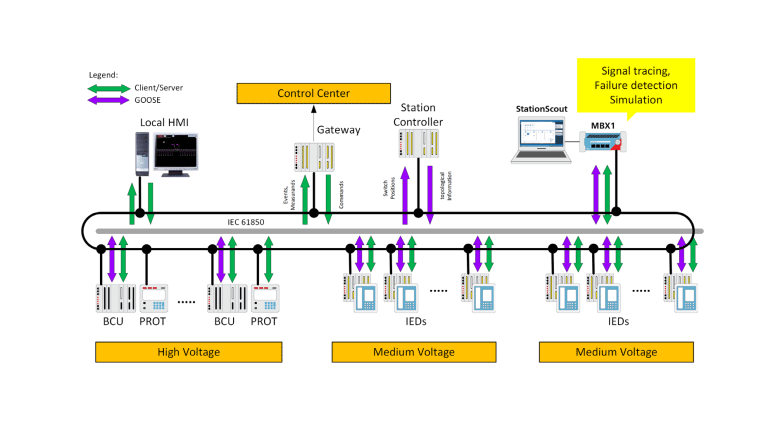

This standard defines two basic types of communication with different services for data exchange between the intelligent electronic devices (IEDs) at the bay level (protection devices, bay controllers, etc.) and the station level (telecontrols gateway, local control system, etc.):

Client/Server (MMS) for communication between a “server” (for example a bay controller) and a “client” (for example a telecontrol gateway), typically used for the control and monitoring of the substation from the remote control center or a local operator workplace. “Report” and “Control” are used as typical services.

GOOSE and Sampled Values (SV) for the exchange of time-critical information between the IEDs, typically used for interlocking functions, exchange of protection signals and also for digitised current and voltage transformer signals (process bus).

An essential component of the standard is the standardised Substation Configuration Language (SCL), which describes the project-specific signals and communication services in a manufacturer-independent form. This means that, in addition to the manufacturer-specific tools, third-party tools can also be used for engineering, testing, commissioning, and ongoing maintenance of the installations.

Command interlocking in the substation

In addition to remote control and monitoring of the primary installation, command interlocking is a standard function that can be found in almost every substation automation system. The command interlocking ensures that the control of a primary equipment does not lead to damage to the electrical equipment or to endangering individuals. For example, the command interlocking prevents the opening of a disconnector under load. Which equipment is to be interlocked, and how, is often specified by the owner of the substation in the form of an interlocking concept. Not just the specific properties of the primary equipment but also operational requirements play a role here. For example, switching from the control center is usually only permitted in the “remote” operating mode (switching hierarchy) and all further commands must be blocked as long as a switching operation has not been clearly completed (1-out-of-n interlocking).

Specific implementation of the interlocking function in the substation control system

In the past, the interlocking functions had been realised in electromechanical relay technology in the respective (bay) control cabinets. Various signals such as “Busbar grounded” or “Switching operation in progress” must actually be hardwired between the individual bays – a complex solution, especially for installations with multiple busbars. Fortunately, IEC 61850 provides a solution that is cost effective and more elegant: The required signals, such as for the switch positions, are exchanged by means of GOOSE services and the calculation of the command release information is implemented, for example, by means of a function plan according to IEC 61131-3. Over time, the following implementation concepts have been developed:

Centralised: Complete interlockings realised in a central unit (for example in the telecontrol gateway)

All release information is calculated centrally in one device and sent to the corresponding bay devices. Benefit: Simple and clearly structured. Disadvantage: No interlocking if the central unit fails.

Decentralised: calculation of Interlockings is fully distributed in each field device. Each bay controller processes all necessary switch positions of the other bays and thus calculates the release information of the switching commands in its bay. Disadvantage: Complex, all bay devices must be updated when the substation is expanded!

Mixed: The bay-related interlocks are implemented in the respective bay device. In addition, a dedicated device (e.g. station controller) calculates the station-wide interlocking (Figure 1). To realise this, the bay devices send their switch positions via GOOSE to a “station controller”, which calculates topological information such as “busbar 1 grounded” and sends this information via GOOSE to the bay devices, where the actual command releases are formed. Benefit: If the central device fails, the bay-related interlocks remain available. Existing field devices are not affected by expansions of the substation!

A similar situation arises when the secondary technology in an existing substation is renewed. Here, too, the new protection and process control devices must often be tested and commissioned bay by bay during operation and without affecting the bays that have already been refurbished.

One possible course of action that has already proved successful in practice is shown by the example of the extension of a medium-voltage installation with a new busbar section:

A new SCD file for the entire installation is created and the new bay IEDs are parameterised. The parameters and operator screens of the existing local HMI, the telecontrol gateway and the station controller are extended by the new bays. The existing bay controllers and protection IEDs remain unaffected.

The new switchgear section is installed together with the IEDs in the substation and tested (still without integration into the existing SAS). First, the data exchange with the existing secondary technology is fully pre-tested by simulating the affected components (gateway, station controller, other bays if necessary) with a modern testing solution such as OMICRON StationScout (Figure 2). The basis for this is the SCD file for the extended substation control system, which describes the existing components and the new bay devices with all signals and communication services. The protection and process control functions of the new IEDs can be tested without affecting the components of the existing installation: StationScout is used to test whether all necessary signals are correctly sent to the local operator workplace, the telecontrol gateway and the station controller. The test engineer also uses this tool to simulate the corresponding topological information which is otherwise calculated by the station controller. The interlocking states calculated in the field devices are visualised and tested in the graphical user interface of StationScout. The command function in StationScout can also be used to check the correct execution of each switching command – all this without affecting the function of the existing process control system.

In the next step, the existing local HMI, the telecontrols gateway and the station controller are loaded with the new parameters for the extended installation. Now StationScout can be used to simulate the IEDs of the new bays (Figure 3) and, as a result, the extended operator screens, event lists, alarm lists, archives, etc. can be checked both in the local HMI and in the control center at the individual signal level (Figure 4). At the same time, by simulating various switching states of the new bays, the correct implementation of the station interlocking in the station controller is tested without having to operate a switchgear within the new medium-voltage installation.

Now that both the new IEDs and the updated existing installation have been successfully tested, the two parts of the installation can be connected, and the interaction of the existing and new components can be tested. Here, StationScout provides support with signal tracking and in the search for any remaining causes of faults, such as incorrect time synchronisation or other parameterisation errors (Figure 1).

Conclusion

The testing solution described here, together with a forward-looking implementation of the interlocking functions, allows the switchgear to be extended during operation. The potential of the IEC 61850 standard can, therefore, be fully exploited in the substation without changing the parameterisation and consequently re-testing the existing field devices.

Authored by:

Christian Brauner, OMICRON, Austria

christian.brauner@omicronenergy.com

Co-author:

Mohit Kumar, OMICRON, India

mohit.kumar@omicronenergy.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.