Power quality: Measuring algorithm of electrical parameters

By EPR Magazine Editorial August 6, 2019 5:03 pm IST

By EPR Magazine Editorial August 6, 2019 5:03 pm IST

The regulations defining power quality by the EN, IEEE & IEC Standards are accepted and followed worldwide. Power quality, what exactly does it mean? It’s not just the power quality, rather it is the usage of electricity; effectively and load dependent. Users generally have major issues in having regulations to most commonly named problems under banner ‘power quality’. It is the general and most familiar terms which describe the parameters of electrical power.

Electricity has become one of the basic necessities of day to day life. Here most inevitable is the energy consumed. However, going a step ahead, we find that most of the energy is been wasted by one means or the other. This waste of energy counts in revenue loss and needs extensive attention to get it under control. Based on this many studies have been undertaken.

The major concern in power quality is due to the modern day equipment’s which generally include variable speed drives and switched mode power supplies, furnaces and varying load conditions. The variety of loads used in process industries, household appliances and other equipment’s produce harmonics, which are one of the key contributors to the loss of energy. Further, resulting in poor power quality and therefore resulting in heavy penalty from electricity board, unexpected maintenance or even damage of equipment.

IEC 61000-4-30 explains the power quality-measuring algorithm of electrical parameters. IEC 61000-4-30 is an IEC standard that defines the correct measuring algorithms for power quality instruments. Moving ahead let’s see what are key issues which mainly address power quality.

Harmonics are generally defined as “a sinusoidal component of a periodic wave or quantity having a frequency that is an integral multiple of the fundamental frequency”. Harmonics can be mostly explained using the musical notes which are created by an instrument while playing. These were known to mankind since long back before the electricity came to existence

Another component of harmonics is inter-harmonics, which are like the shredded pieces of mud in a pile of wheat. To explain the inter-harmonics let us take an example of voltage waveform, comprised of 60 Hz and 200 Hz signals. Integral multiples of 60Hz correspond to 120, 180, and 240 and so on. However, if 200Hz is seen then the resultant calculation may result a varied result in the 3rd or 4th Harmonic if considered for 200 Hz. These in-between frequencies are termed as inter-harmonics.

In order to keep track on the harmonics, IEEE has defined the limits shown in below table.

General harmonic generating loads are:

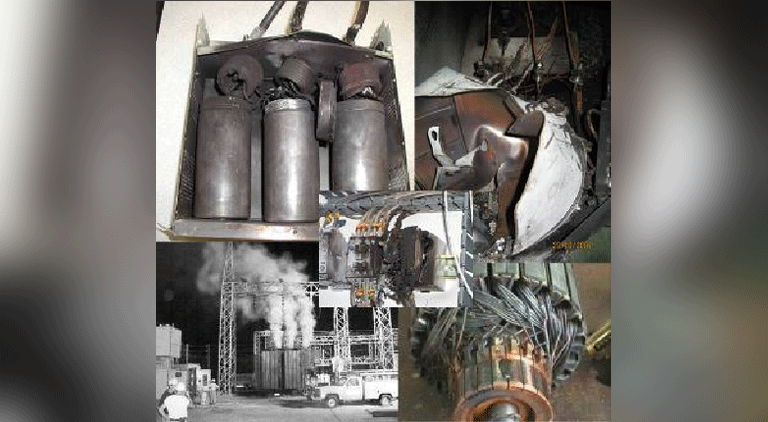

Harmonics has very much impact on the system and few of the negative impacts seen are:

Flickers – An unsteady movement of a flame or light that causes rapid variations in brightness OR Flickering is the opposing changes in intensity of luminosity. These are generally caused due to fluctuations in voltages. Flicker is generally caused due to loads, which draw more current during the processes such as;

According to an article by Dr Kurt Schipman and Dr François Delincé, “the best electrical supply would be a constant magnitude and frequency sinusoidal voltage waveform. The power quality of a system expresses to which degree a practical supply system resembles the ideal supply system.

Poor power quality can be described as any event related to the electrical network that ultimately results in a financial loss. Possible consequences of poor power quality include:

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.