ERDA’s Solar Photovoltaic Modules Test Facility

By EPR Magazine Editorial September 5, 2023 12:14 pm IST

By EPR Magazine Editorial September 5, 2023 12:14 pm IST

ERDA Lab has tested solar modules for 10+ years and is accredited by NABL and MNRE. Services include testing, fieldwork, and R&D with advanced equipment and innovations like self-cleaning coatings and robotic cleaning.

Electrical Research and Development Association’s (ERDA) solar photovoltaic modules evaluation laboratory has been providing solar photovoltaic module testing services to the nation for more than one decade. This laboratory is accredited by NABL and approved by MNRE, Government of India. Services are provided under ERDA’s three business verticals of “testing and evaluation”, “Field services” and “R&D and expert services” as per the following details.

Major services for solar photovoltaic modules:

Testing and Evaluation: Complete test facilities for solar photovoltaic modules for BIS certification testing, which is now mandatory, as per the Quality Control Order Issued by MNRE (Govt. of India) as per the following Indian standards as well as the following International standards:

| Sr.No. | Standard Title/Product | IS / IEC Standard |

| 1 | Crystalline Silicon Terrestrial Photovoltaic (PV) Modules | IS 14286: 2010IEC 61215: 2021, IEC 61730-2: 2016 |

| 2 | Thin-film terrestrial Photovoltaic (PV) Modules | IS 16077: 2013IEC 61215: 2021 IEC 61730-2: 2016 |

| 3 | Solar Home Lighting System | As per MNRE Specifications |

| 4 | Solar Street Lighting System | As per MNRE Specifications |

| 5 | Solar Lenten | IS 16476 (Part-1 & 2): 2017As per MNRE Specifications |

Infrastructures for evaluation of solar photovoltaic modules:

Solar Sun Simulator, Class AAA to carry out Maximum power determination, Performance at STC conditions and performance at low irradiation.

Climatic chamber and humidity chamber to carry out Thermal cycling test, Humidity freeze cycle test and damp heat test.

EL (Electro luminance) tester to find out micro-cracks in PV modules

NMOT & Outdoor exposure test set up to determine how the electrical performance of the module varies with load at NMOT.

Wet leakage current tester to evaluate the insulation of the module under wet operating conditions.

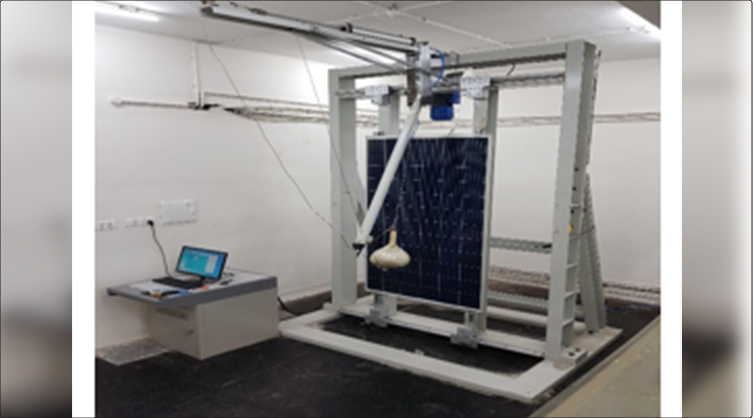

Mechanical load tester to determine the ability of the module to withstand a minimum static load.Hail tester to verify that the module is capable of withstanding the impact of hail.

Bypass diode tester to assess the adequacy of the thermal design and relative long-term reliability of the bypass diode.

Module breakage tester to provide confidence that the risk of physical injuries can be minimized if the PV module is broken in its specified installation

UV Preconditioning test chamber to precondition the module with ultra-violet (UV) radiation.

Hot-spot endurance test chamber to determine the ability of the module to withstand hot-spot heating effects.

Field services and R&D initiatives at ERDA

ERDA undertakes onsite testing of solar PV modules and arrays. Major infrastructure for the performance of onsite solar module testing includes an advanced PV analyser (I-V Curve Tracer) for commissioning, auditing and troubleshooting of PV systems, an IR camera for thermal performance monitoring of PV systems, and monitoring and analysis of complete solar PV systems.

As a part of the R&D initiative, ERDA has developed some key technologies for solar modules such as anti-dust, self-cleaning nanocrystalline coating for solar panels, and an automatic robotic arm for solar panel cleaning.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.